Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > SOP Package Explained: Definition, Features, and Applications

ICs are at the heart of modern electronics, operating everything from consumer devices such as smartphones and computers to commercial or automotive control applications, all the way through to industrial automation equipment, in all shapes and sizes. The silicon chip itself won’t work well at all if there isn’t reliable packaging available. The package not only protects the IC but also makes it possible for the IC to be interconnected with a printed circuit board (PCB).

One of these common package types includes the SOP. The SOP has evolved into a flexible and cost-effective IC packaging type, able to find a middle ground among performance and size and manufacturability. Let’s look at the SOP package definition and structure characteristics, as well as the main types of SOP packages. We will also compare SOIC in terms of its role as a package type and the advantages of SOP packages, along with introducing future trends.

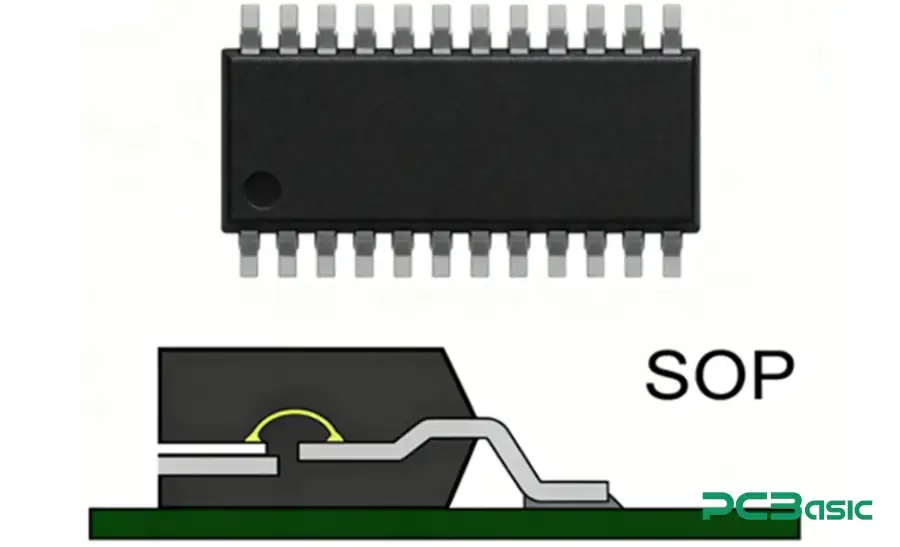

SOP (Small Outline Package) is a surface-mount IC package that is used where space is at a premium and high reliability is required. SOP is also referred to as the surface mount package type, and compared with old through-hole packages, it has leads in gull-wing leads extending from both sides of the package and can be mounted directly on a PCB by soldering.

The SOP is a rectangular SMD with the leads on the sides of the device's body. The leads are gull-wing, so they’re great for drag soldering as a bonus. This compact size allows for high-density design of consumer products, automotive applications and more.

The SOP was developed from the 1970s DIP, and due to its small size is used primarily for surface mount devices. The miniaturization of IC packages was also required with the advancement of circuits and devices. These demands were made possible with the SOP package by minimizing package thickness and lead length, while saving board space. Many different types of SOP packages have also been proposed and developed such as TSOP (Thin SOP), SSOP (Shrink SOP) etc, according to diverse design requirements.

There are several different kinds of packages for IC in our electronics products: DIP, QFP, QFN, BGA, and so on, for cost, ease of manufacturing, and performance. The middle-range SOP package gives a nice tradeoff. In high-performance computing, BGA or other advanced packages are commonly used. However, SOP is still an attractive package in terms of cost and reliability/density for small form factor applications. Most common in memory ICs, MCUs and analog devices.

The SOP package is quite simple but really powerful. It consists of:

● Compact Form-factor: They are much smaller than DIP packages.

● SMT (Surface Mount Technology) Compatible: intended for automated PCB mounting and soldering.

● Electrical Performance: Good performance lowering the inductance from shorter lead length.

● Adaptable: Comes in a wide range of types for various densities and applications.

● Cost-saving: Cheaper than other cutting-edge chip packaging forms such as BGA.

Over the decades, many SOP types have been created to satisfy new requirements in the electronics world. The most common ones are:

Narrow SOP (NSOP)

It is ideal for applications needing small board footprints, and is widely used in compact I/O modules, sensors, and small controllers.

Wide SOP (WSOP)

An enlarged body width is characteristic of Wide SOP, which can accommodate a higher pin number. It is mostly used in both memory ICs and devices with multiple connections.

Thin Small Outline Package (TSOP)

Unlike the conventional SOP, the TSOP is designed with a thinner body. It is very popular among memory ICs such as DRAM and Flash. Thanks to this package, the total thickness of the device is reduced, and therefore it is considered for slim electronic equipment.

Shrink Small Outline Package (SSOP)

Shrink SOP is a pitch-reduced version of SOP, which enhances pin density. It is a high-density packaged board that saves the PCB mounting area and is used as a transition for fine-pitch IC packages.

SOP is one of a variety of types of chip packages. The SOP is smaller than the DIP in size and compatible with automatic pick-and-place mounting. It lacks the density characteristics of both the QFN (Quad Flat No Lead) and the QFP(Quad Flat Package). However, it is simpler for production.

It’s this balance that also makes the SOP package type increasingly popular with mid-range products, where cost and assembly line space are just as important criteria for selection as is miniaturization.

The most common comparison may be SOIC vs SOP. The terms are often confused with each other, commonly used in error for the other, but they hold more than a few differences.

|

Feature/Aspect |

SOIC (Small Outline Integrated Circuit) |

Small Outline Package (SOP) |

|

Width Options |

Sold primarily in thin and wide (3.9 mm & 7.5 mm body widths) |

There are many subtypes: NSOP, WSOP, TSOP, SSOP, etc. |

|

Body Size |

Slightly bigger than the majority of SOP forms |

Can be narrower, thinner, or shrunk depending on subtype |

|

Pin Pitch (Lead Pitch) |

Typically 1.27 mm |

Can vary from 1.27 mm (standard) down to 0.65mm or smaller (e.g., SSOP, TSOP). |

|

Lead Form |

Gull-wing leads extending outward |

Gull wing leads, but dimensions and pitch depend on subtype |

|

Package Variants |

Narrow SOIC, Wide SOIC |

Narrow SOP (NSOP), Wide SOP (WSOP), Thin SOP (TSOP), Shrink SOP (SSOP) |

|

Thickness |

Standard thickness (≈1.5 mm) |

Variants of SOP include thinner types (the thickness of TSOP can be ~1mm or less). |

|

Pin Count |

Generally between 8 and 44 pins |

Can go from 8 up to 64 pins or more, depending on the subtype |

|

Cost |

Relatively cheap because of widespread adoption and standardisation |

Varies. Standard SOPs are cost-effective, while advanced variants (e.g., TSOP) can be more expensive |

|

Use in Memory ICs |

Less common for high-density memory |

TSOP and SSOP are widely used in DRAM, Flash, EEPROM, and packaging. |

|

Design Flexibility |

Less flexible, follows strict standards |

More flexible. Manufacturers adapt dimensions for performance, density, or board space |

|

Thermal Dissipation |

Moderate thermal performance |

Depends on subtype and SOP. Wider/thicker SOPs usually can handle more power, while thin versions dissipate less heat. |

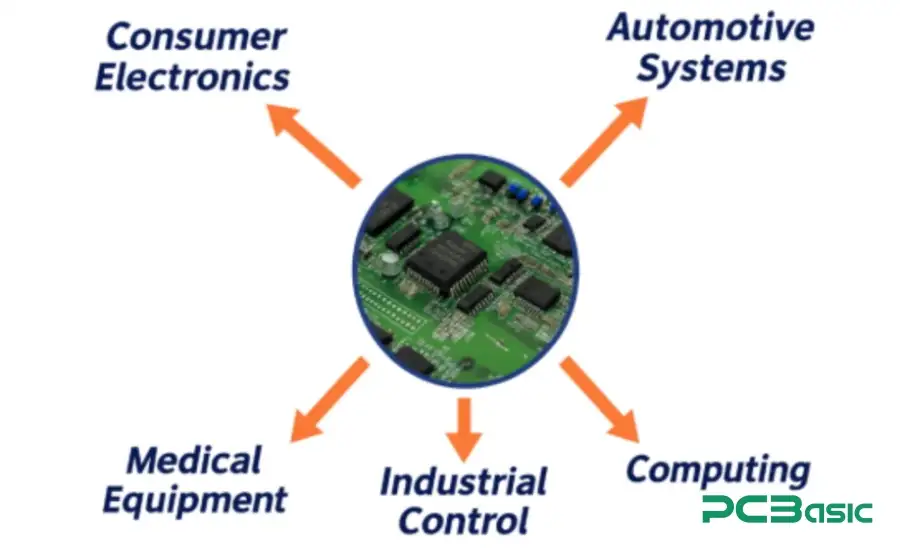

It is versatile and has been applied to many industries, so it is common practice. Typical applications include:

● Consumer electronics: Applied to the smartphone, TV, and game machine AV products for memory/utilization ICs.

● Automotive Systems: Typical also in micro-controllers and sensor interfaces.

● Computing: Logged for DRAM, Flash, and EEPROM memory in PCs and servers.

● Industrial Control: PMIC, Motor Drivers, and communication chips.

● Medical Equipment: the small size for portable diagnostics.

● Small footprints save PCB space.

● Reduced parasitics better than the DIP.

● Excellent SMT solderability.

● Can support Various SOP Packaging forms (NSOP, WSOP, TSOP, SSOP).

● Inexpensive compared with next-generation IC packaging types such as BGA.

● Lead pitch limitation: Cannot be achieved with ultra-fine pitch (e.g., QFN or BGA).

● Thermal performance: Not nearly as good as exposed-pad packages.

● Pin count: Poor choice for very high I/O counts.

The electronics industry keeps advancing, driving the chip packaging forms into more miniaturization and higher performance. Future trends include:

● Integration with Advanced Packaging: SOP package can support an exposed thermal pad for improved thermal performance.

● Thinner Variants: Demand for portable electronics will drive thinner SOP package types.

● Hybrid Package: Integration with QFN or SiP (System in Package) solutions for improved performance.

● Sustainability: Eco-friendly molding compounds and lead-free manufacturing meets global standards.

Despite such trends, the SOP package will continue to be a commonly used IC package type obtained at low cost and finding use in commodity applications.

The SOP package is one of the older and most versatile IC packages in the electronics industry. From its inception as a space-saving DIP alternative to the modern incarnations like TSOP and SSOP, SOP has walked a tightrope between performance cost and manufacturability.

Looking at SOIC vs SOP, you may not notice much of a difference, but there is enough of a difference to create issues that engineers need to be aware of when comparing datasheets. Widely used in consumer electronics, automotive systems, computing, and industrial equipment, the SOP remains a popular choice of packaging type for chips. Although smaller and more advanced packages may be superior with the progress of technology, the small outline package still plays an important role in electronics.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.