Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Exploring SMT Connectors in PCB Design

In the rapidly evolving field of electronics, Surface Mount Technology (SMT) has become a cornerstone of modern printed circuit board (PCB) design. SMT has transformed how electronic components are mounted and connected, offering significant advantages over traditional through-hole methods. At the heart of this transformation are SMT connectors, which play a crucial role in ensuring efficient and reliable connections between various components on a PCB. This blog aims to provide a comprehensive exploration of SMT connectors, their types, benefits, and applications in today's electronic devices.

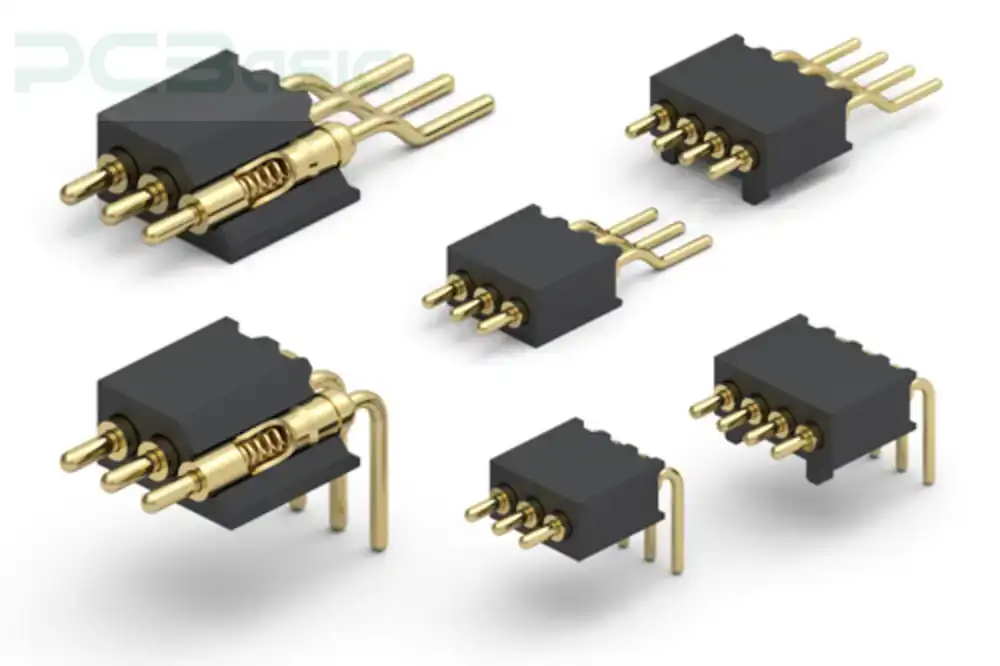

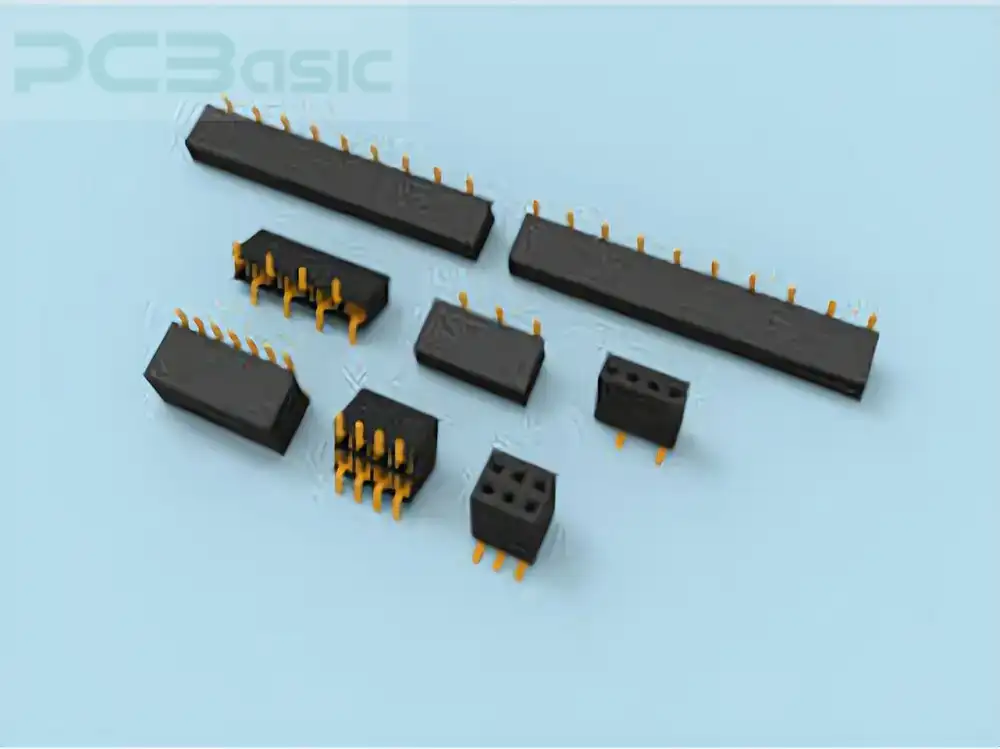

SMT connectors are specialized components designed to be mounted directly onto the surface of a PCB. This contrasts with through-hole technology, where component leads are inserted into drilled holes on the board. The adoption of SMT offers several benefits, including reduced space requirements and improved manufacturing efficiency.

The use of SMT connectors offers several advantages over traditional connection methods:

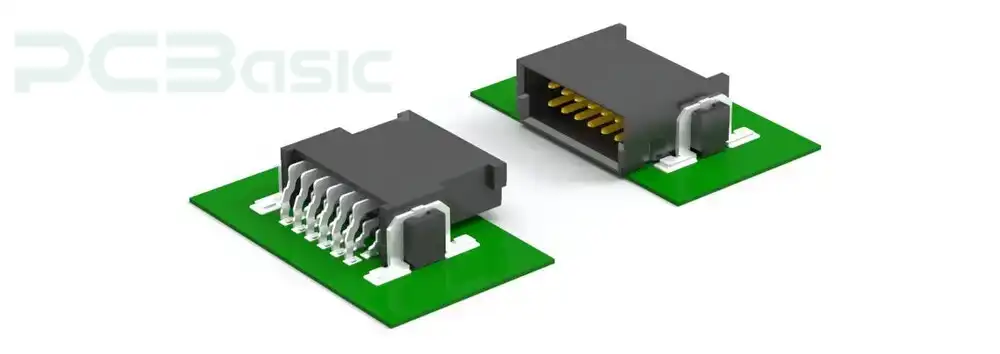

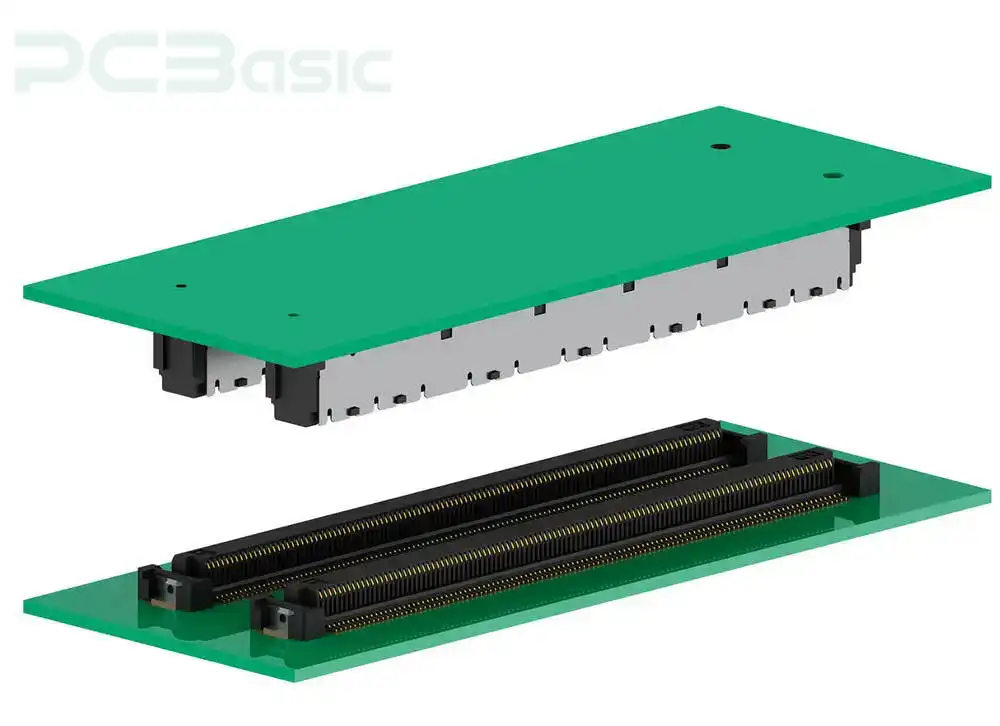

The versatility and efficiency of SMT connectors make them ideal for a wide range of applications across various industries:

Understanding the distinction between SMD (Surface Mount Devices) and SMT (Surface Mount Technology) is crucial for anyone involved in PCB design:

The primary advantage of using SMDs with SMT is the ability to achieve higher component density on PCBs, leading to more compact and efficient electronic designs.

The evolution of PCB design has been significantly influenced by advances in Surface Mount Technology. With their ability to support high-density layouts and automated assembly processes, SMT connectors have become indispensable in modern electronics manufacturing. Whether you're comparing SMD vs. SMT or exploring various connector types like connector sockets, PCB edge clips, or specific configurations like angle type, understanding these components is crucial for designing efficient and reliable electronic systems.As electronic devices continue to shrink in size while expanding in capability, the role of SMT connectors will only grow more critical. Their integration into PCBs ensures that today's devices can meet tomorrow's technological challenges with ease. By embracing these innovations, engineers can push the boundaries of what is possible in electronics design, creating products that are not only smaller but also more powerful and reliable than ever before.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.