Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Accelerometer Sensors – A Complete Guide

Motion sensing technology is a ubiquitous technology in modern electronic products. From the screen rotation of smartphones to complex applications in automobiles and industrial robots, sensors play a crucial role. Some devices rely on accelerometer sensors to respond to various movements, tilts, and vibration changes. Accelerometer sensors are their core components.

So, what exactly is an accelerometer sensor and how does it work? In this article, we will explain accelerometer sensors. We will analyze different types of accelerometer sensors, explain their working principles and practical applications. At the same time, we will also explore how accelerometer sensors are integrated with PCBs and PCBAs.

Before delving into accelerometer sensors, we will first explain the concept of an accelerometer. So, what is an accelerometer?

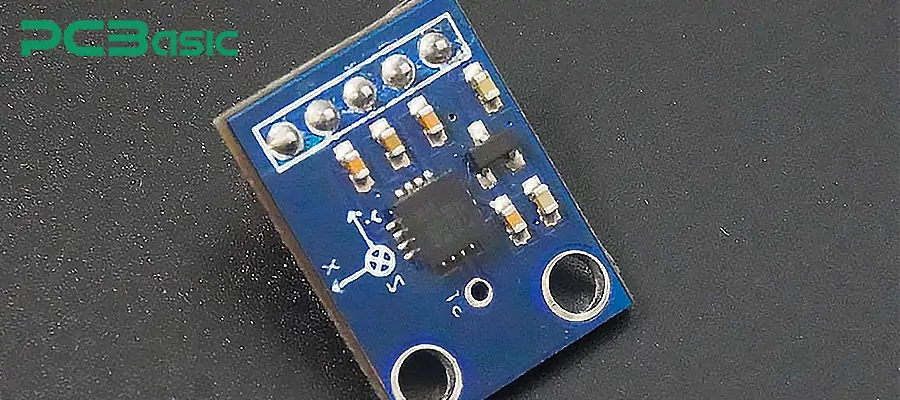

An accelerometer is an electronic device used to measure the accelerometer of an object (that is, the object's speed or speed change). In simple terms, it can detect any movement or tilt of the object. It usually measures along the X, Y, and Z axes in three-dimensional space. Whether it is detecting tiny vibrations or the orientation of the device, the accelerometer plays a crucial role.

The common applications of accelerometers include:

Motion sensing: Tracking the movement, speed or direction of the device.

Tilt measurement: Understanding the angle of an object relative to gravity.

Vibration detection: Measuring the oscillation or shaking of an object or structure.

Fall detection: Used in safety applications such as smartphones, wearable devices and medical equipment.

Inertial navigation: Used in vehicles, drones and aerospace to track position and speed.

To achieve these applications, accelerometers typically rely on their internal sensor modules. These modules convert accelerometer into usable electrical signals.

The accelerometer sensor refers to the specific sensing module within the accelerometer, which is used to detect accelerometer and convert it into an electrical signal. Its core component usually includes a sensitive mass block or a proof mass. When accelerometer acts on the accelerometer, the mass block will undergo displacement, and the connected circuit will then convert this displacement into an electrical signal.

The main components of an accelerometer sensor include:

Inductive element: used to detect accelerometer, usually a mass-based or capacitance-based structure.

Signal processing circuit: converts the displacement of the inductive element into an electrical signal.

Output interface: transmits the processed data to the system for further use (analog or digital output).

Accelerometer sensors are usually embedded in the system to capture and transmit data related to motion. In some contexts, the term accelerometer refers to the complete device, while the accelerometer sensor emphasizes the sensing element. Below is a summary of some comparisons between accelerometers and accelerometer sensors. This will help you better understand the differences and connections between the two.

|

Feature |

Accelerometer |

Accelerometer Sensor |

|

Definition |

A device used to measure accelerometer, tilt, and vibration. It can be a standalone unit or part of a system. |

A specific module or component within an accelerometer that detects accelerometer and converts it to an electrical signal. |

|

Scope |

Can refer to the entire device or system used for accelerometer measurement. |

Refers to the individual sensing component of the accelerometer, focusing on detection and signal conversion. |

|

Function |

Measures accelerometer, tilt, or vibration, often including additional components for processing data. |

Focuses on sensing and converting accelerometer data into electrical output. |

|

Applications |

Used in a wide range of applications such as smartphones, cars, industrial machines, and aerospace systems. |

Typically found in embedded systems such as smartphones, wearables, and robots, providing input to larger systems. |

|

Composition |

Consists of the sensor, signal processing electronics, and possibly additional components for specific functions. |

Primarily composed of the sensing element (e.g., proof mass) and electronic components for signal processing. |

|

Role in the System |

The full device used to measure and process accelerometer, tilt, or vibration. |

The core component is responsible for detecting accelerometer and providing the raw data to be processed. |

We have already mentioned a small mass block (proof mass) earlier. In fact, the accelerometer sensor works by measuring the displacement of this small mass block under the influence of external accelerometer. In simple terms, the accelerometer sensor detects the changes that occur when an object is in motion. Here is a brief description of its working process:

First, there is accelerometer detection. When an external force (i.e., accelerometer) acts on the accelerometer, the proof mass inside it will undergo displacement. The magnitude of this displacement is proportional to the external applied accelerometer - that is, the greater the external accelerometer, the greater the displacement of the mass block.

Next comes signal conversion. The sensor detects the displacement of the proof mass through different technologies such as capacitance, piezoelectricity, or piezoresistivity, and then converts it into an electrical signal.

Capacitive accelerometers detect accelerometer by measuring the change in capacitance when the mass block moves.

Piezoelectric accelerometers generate charges when the mass moves and convert them into electrical signals.

Piezoresistive accelerometers measure the resistance change caused by the mass displacement and convert it into an electrical signal.

Then, the detected electrical signals are processed by the internal circuits of the sensor, and an output signal related to the accelerometer is generated. (This signal can be either an analog signal or a digital signal, depending on the design of the sensor.) Thus, the signal is directly related to the accelerometer.

Finally, the processed signal is transmitted through an interface (such as I2C, SPI, or analog voltage) to the system for further processing and application. By continuously detecting and measuring these displacements, the accelerometer sensor can track the movement of an object in multiple directions. This is the working process of the accelerometer sensor.

There are various types of accelerometer sensors, and each type uses different technologies to measure accelerometer. Each type is designed to be suitable for different applications based on its unique features and advantages. Among them, the most commonly used ones are piezoelectric, piezoresistive, capacitive, and servo accelerometers. Next, we will introduce them to you one by one.

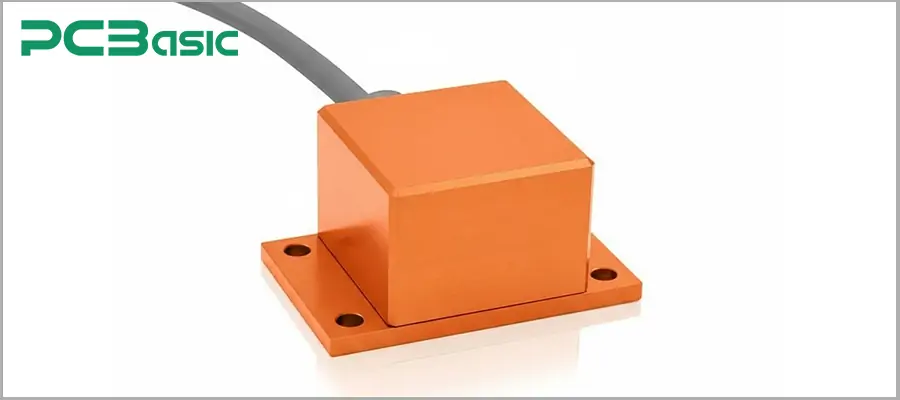

The piezoelectric accelerometer sensor operates by using piezoelectric crystals. When it is subjected to mechanical pressure (such as vibration or impact), it generates an electric charge. This sensor is highly sensitive and can detect high-frequency vibrations and impacts. Moreover, it is sturdy and durable and can function normally in harsh environments. However, its drawback is that it requires signal regulation to obtain accurate readings, and its measurement effect is poor for low-frequency accelerometers.

Common applications include:

Vibration monitoring of mechanical equipment

Impact testing in the automotive and aerospace fields

Structural health monitoring of buildings and bridges

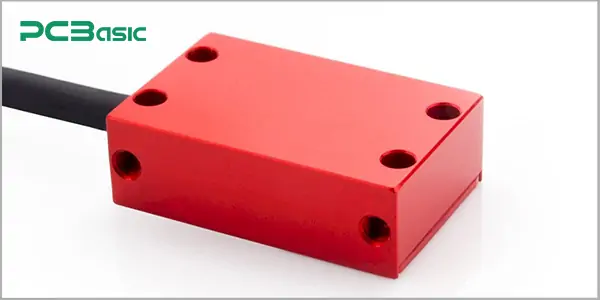

The piezoresistive accelerometer sensor operates by measuring the change in resistance when stress is applied to the sensor. This type of sensor uses piezoresistive materials. When the internal mass block moves due to external accelerometer, the resistance of the material changes. This type of sensor is reliable and stable in performance, has high cost-effectiveness, and is well-suited for measuring low-frequency and medium-frequency accelerometers. However, its performance is limited in high-temperature environments, and it requires regular calibration.

Common applications include:

Crash testing, impact sensing, and load measurements

Pressure and load measurements in industrial systems

Impact sensing in various mechanical applications

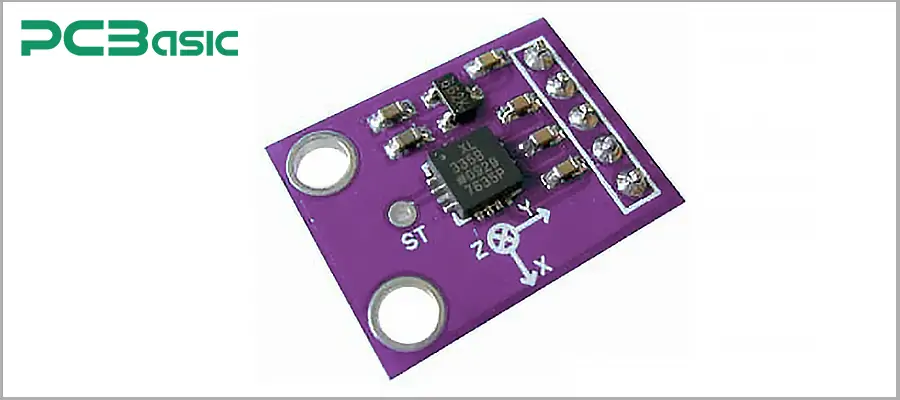

Capacitive accelerometer sensors operate by measuring the displacement between two capacitor plates. When the sensor's internal mass is displaced by accelerometer, the distance between the plates changes, causing a change in capacitance. Capacitive sensors are known for their compact size and low power consumption, while also offering high precision and resolution. However, these sensors are less suited for very high-frequency or high-amplitude vibration environments.

Common applications:

Screen orientation and motion sensing in smartphones

Activity tracking in wearable devices

Servo accelerometer sensors maintain the position of a proof mass through a feedback mechanism. A feedback mechanism (such as electrostatic or electromagnetic force) continuously adjusts the mass's position, with the required displacement proportional to the accelerometer. While this accelerometer sensor is complex and expensive, and requires a power source to maintain the feedback mechanism, it offers high precision and accuracy, operating stably across a wide range of accelerometers.

Common Applications:

Navigation and positioning in aerospace

Missile guidance and aircraft stabilization systems in defense

High-precision industrial equipment

Summary of Accelerometer Types:

|

Accelerometer Type |

Working Principle |

Advantages |

Disadvantages |

|

Piezoelectric |

Generates electrical charge when mechanical stress is applied. |

High-frequency response, rugged, effective in harsh conditions. |

Requires signal conditioning, less effective for low-frequency accelerometers. |

|

Piezoresistive |

Measures change in resistance when stress is applied. |

Reliable, cost-effective, stable measurements. |

Limited high-temperature performance, requires calibration. |

|

Capacitive |

Measures displacement between capacitor plates. |

Low power, compact, high precision. |

Limited for high-shock applications, less suited for high-frequency. |

|

Servo |

Uses feedback to maintain constant position of the proof mass. |

High precision, stable performance, ideal for sensitive applications. |

Complex, expensive, requires power for feedback mechanism. |

Accelerometer sensors are widely used in various industries. In the previous section, we introduced the different types of accelerometer sensors and briefly discussed their applications. Next, we will introduce the applications of accelerometer sensors using specific examples.

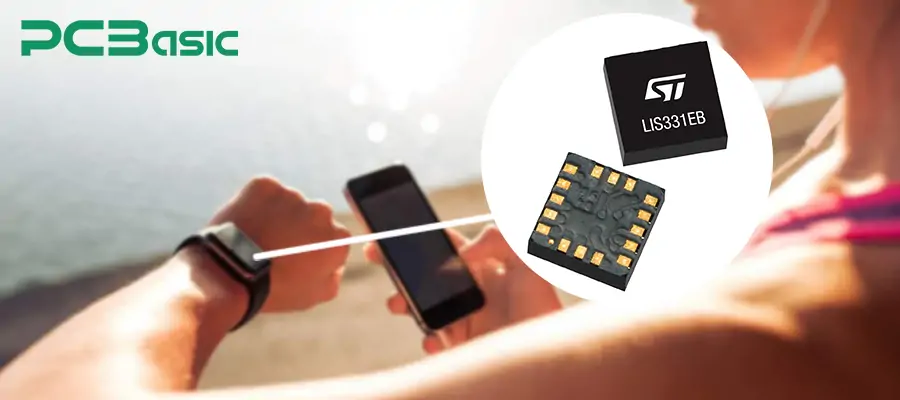

Accelerometer sensors are found in nearly all consumer electronics devices. For example, smartphones and wearables can switch from portrait to landscape mode, instantly adjusting the display interface. This is the result of the built-in accelerometer. Besides screen rotation, accelerometer sensors also perform motion detection. For example, a Xiaomi Mi Band or Apple Watch can analyze changes in arm accelerometer to calculate the user's step count, distance traveled, and even calorie consumption. This is where the accelerometer plays a crucial role.

In the automotive industry, the accelerometer sensor plays a crucial role in safety. For example, in the safety systems of vehicles like the Tesla Model 3 and the Volkswagen Golf, accelerometer sensors monitor changes in vehicle accelerometer in real time. If a sudden deceleration occurs, the airbags are immediately activated to protect the occupants. Another example is the Toyota Prado's Electronic Stability Control (ESC), which uses accelerometer sensors to sense the risk of the vehicle rolling during sharp turns and proactively applies the brakes to prevent rollovers.

Accelerometer sensors also provide compensation for car navigation. Modern vehicles often combine accelerometers with gyroscopes. This combination offers even greater functionality. They are often used in advanced driver assistance systems (ADAS), electronic stability control, and predictive safety features. Accelerometers measure linear accelerometer, while gyroscopes detect rotational motion. Combining these two enables augmented reality (AR), virtual reality (VR), and more accurate navigation.

Accelerometer sensors are also widely used in the industrial and energy sectors. For example, in earthquake monitoring, accelerometer vibration sensors detect subtle movements in the earth's crust, instantly issuing warnings and buying valuable time for evacuation. In the power industry, accelerometer sensors are also installed on ultra-high voltage transmission lines to monitor vibration and galloping in strong winds, preventing line breaks and widespread power outages. In robotics, accelerometer sensors maintain the balance and stability of equipment.

Accelerometer sensors are indispensable across various industries.

Accelerometer sensors are widely used in modern electronic systems due to their advantages:

1. They can accurately detect linear accelerometer, tilt angle, and small vibrations in real time. This allows devices to maintain stable performance in scenarios requiring high-precision motion detection.

2. Accelerometer sensors utilize microelectromechanical systems (MEMS) technology, resulting in compact size and low power consumption, making them ideal for use in Internet of Things (IoT) devices and smartphones. This characteristic perfectly aligns with the changing trends in modern electronic devices.

3. Some accelerometer sensors can maintain stable operation in extreme temperatures, high vibration, and electromagnetic interference environments, making them ideal for demanding environments such as automotive, aerospace, and defense.

4. Accelerometers come in compact packages, making them easy to install and test.

The advantages of accelerometer sensors mentioned above ultimately require specific circuit design and manufacturing processes to realize. Regardless of the industry in which they are used, the integration of the sensor with the PCB/PCBA is crucial for the long-term stability of the system.

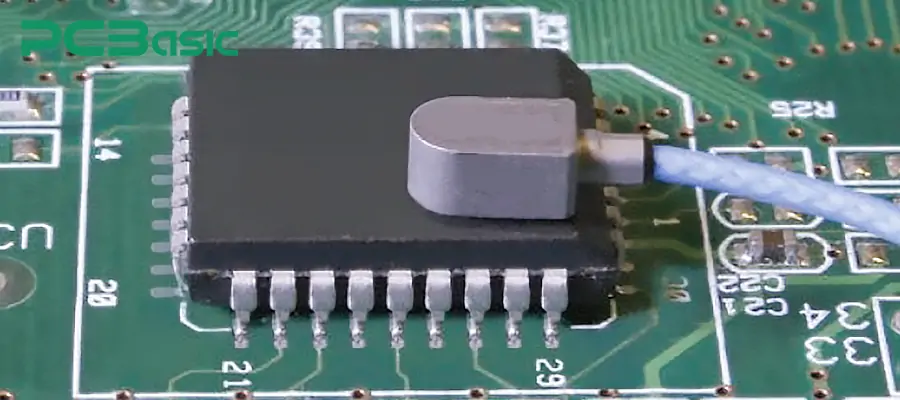

When mounted on a PCB, an accelerometer essentially operates according to the same principle: detecting the displacement of an internal mass and converting it into an electrical signal. The difference is that on the circuit board, these electrical signals are directly transmitted to a microcontroller (MCU) or dedicated processing chip for analysis. In other words, on a PCB, the accelerometer sensor is more than just a simple signal conversion process; it integrates a comprehensive process with circuitry, interfaces, power management, and other components.

To ensure the accuracy and reliability of accelerometer sensors in practical use, careful consideration must be given to the PCB layout. Considerations include:

The accelerometer sensor should be positioned as far away from the power module, power devices, or motor drive as possible to avoid interference from noise and mechanical vibration.

The sensor must be securely fastened to prevent errors caused by board flex or solder joint stress.

A ground plane or shielding structure should be included in the PCB layout to minimize the impact of electromagnetic interference on the sensor output.

Signal lines should be kept as short as possible and avoid running parallel to high-frequency traces to reduce coupled noise.

These details directly impact the accuracy and long-term stability of the accelerometer in the PCB.

Accelerometer sensors can be soldered to a PCB using SMT or THT techniques. After soldering, the board needs to be functionally tested:

Apply a known accelerometer in a laboratory environment to verify the accuracy of the sensor output.

Check the bias, sensitivity, and linearity to ensure they meet design requirements.

Run a test program on the entire PCBA to confirm that the signal can be correctly read by the system.

The effectiveness of an accelerometer sensor depends not only on the performance of the component itself, but also on sound circuit design, precise manufacturing processes, and rigorous functional testing. Only in this way can it ensure long-term stability and reliability in real-world applications.

Accelerometer sensors are essential components in various electronic products, serving as a core element for accurately detecting motion, tilt, and vibration. Achieving optimal accelerometer performance requires sound circuit design, reliable manufacturing processes, and rigorous functional testing. Accelerometer sensors are more than just simple components; they are crucial enablers of intelligent systems.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.