Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Metal Core PCBs (MCPCBs)

In modern electronic products, while devices are becoming smaller and more powerful, the requirements for heat dissipation of the products are also getting higher. Traditional FR4 or CEM3 circuit boards often struggle to cope with these high thermal loads, which can easily lead to overheating, reduced reliability and shortened lifespans. To solve these problems, metal core circuit boards (MCPCBs) have become a better choice.

Unlike standard fiberglass substrates, metal core printed circuit boards use metals such as aluminum or copper as their substrates, significantly enhancing heat dissipation performance. Nowadays, metal core PCBs have been widely used in various industries. With excellent thermal conductivity and mechanical strength, metal core printed circuit boards can significantly extend the product lifespan and enhance reliability.

In this article, we will introduce what an MCPCB is, delve into its structure, materials, advantages and types, and demonstrate its applications in various industries. Finally, we will also compare metal core PCBs, FR4 and ceramic circuit boards to help you find the most suitable design solution.

A metal core printed circuit board is also known as a metal core PCB, a metal clad PCB, a thermal clad PCB, a metal-based PCB, or simply MCPCB. It is a circuit board specially designed to solve the heat dissipation problem. Compared with ordinary FR4 or CEM3 boards, the aluminum or copper substrate of MCPCB has a much better thermal conductivity. In this way, the heat generated by high-power components can be quickly conducted to the metal core through the insulation layer, preventing the circuit board from overheating and making the equipment more stable and reliable.

After integrating the MCPCB into the design, engineers no longer have to rely on bulky heatsinks or fans. The final circuit board obtained is both compact and durable, and has a strong heat dissipation performance. This type of circuit board is particularly suitable for use in LED lighting, automotive electronics and power systems. In most cases, aluminum has become the mainstream choice due to its low cost, light weight and ease of processing, while copper core PCBs are more commonly found in applications with extremely high-performance requirements.

In simple terms, an MCPCB is not an ordinary circuit board but a circuit board with a built-in heat dissipation function. It has become an indispensable key material in various high-power and heat-sensitive electronic products today.

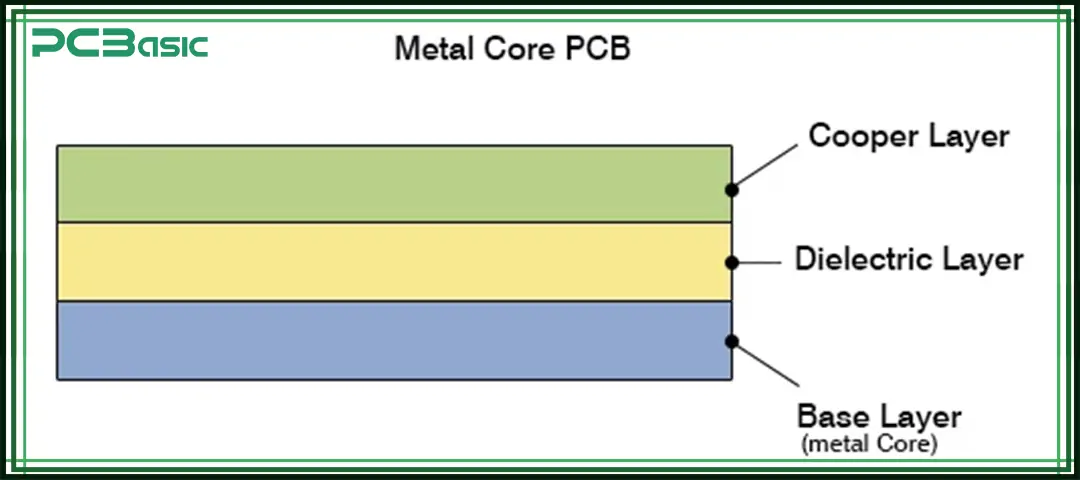

The basic structure of the MCPCB is very similar to that of a common PCB, but it has an additional layer of metal core board, which is precisely the key to significantly improving its heat dissipation performance. A typical metal core PCB usually consists of the following parts:

• Solder mask layer: It protects the circuit and prevents short circuits or oxidation.

• Circuit layer: Composed of copper foil (generally 1-6 oz, most commonly 1-2 oz), it is used to conduct current.

• Thermally conductive dielectric layer: It is the core layer that is used to conduct the heat generated by the copper foil to the metal substrate.

• Metal core board: Aluminum is mostly used (low cost and easy to process), and copper can also be used (better heat dissipation effect).

• Optional heatsink backing: It is used additionally when stronger heat dissipation is required.

In multilayer metal core printed circuit boards, the metal core is generally placed in the center of the circuit board. For example, in a 12-layer metal core PCB, the metal core is positioned in the middle, with 6 layers on each side. This structure not only makes the circuit board more stable but also enables heat to be evenly distributed.

Due to the combination of the copper circuit layer, thermally conductive dielectric and robust metal core circuit board, the thermal efficiency of the MCPCB is 8-9 times faster than that of the ordinary FR4 board. Therefore, metal core printed circuit boards are highly suitable for scenarios with high power and high heat generation.

In MCPCBs, the selection of materials is very crucial. Unlike traditional FR4 or CEM3 circuit boards, an MCPCB relies on metal core boards to enhance heat dissipation. Different substrates not only affect thermal conductivity, but also influence cost, weight and processing technology. Common materials are aluminum and copper, while steel alloys and ceramics are mostly used in special applications.

MCPCB Material Comparison Table

|

Material |

Thermal Conductivity |

Weight |

Cost |

Processing Difficulty |

Typical Applications |

|

Aluminum |

2.0–5.0 W/m·K, medium |

Light |

Low |

Easy |

LED lighting, audio devices, communication equipment, and consumer electronics |

|

Copper |

>200 W/m·K, very high |

Heavy |

High |

Difficult |

High-power electronics, automotive regulators, inverters, and industrial control systems |

|

Steel Alloys |

Low |

Heavy |

Medium |

Moderate |

Applications requiring high mechanical strength, specialized industrial equipment |

As we can see from the above table, the aluminum core PCB offers the best cost performance and is suitable for most common applications. Copper core PCBs have stronger heat dissipation and performance, and are mainly used in the most demanding high-end systems. While steel alloys have average thermal conductivity, they are often used in equipment that requires high mechanical strength because of their good rigidity.

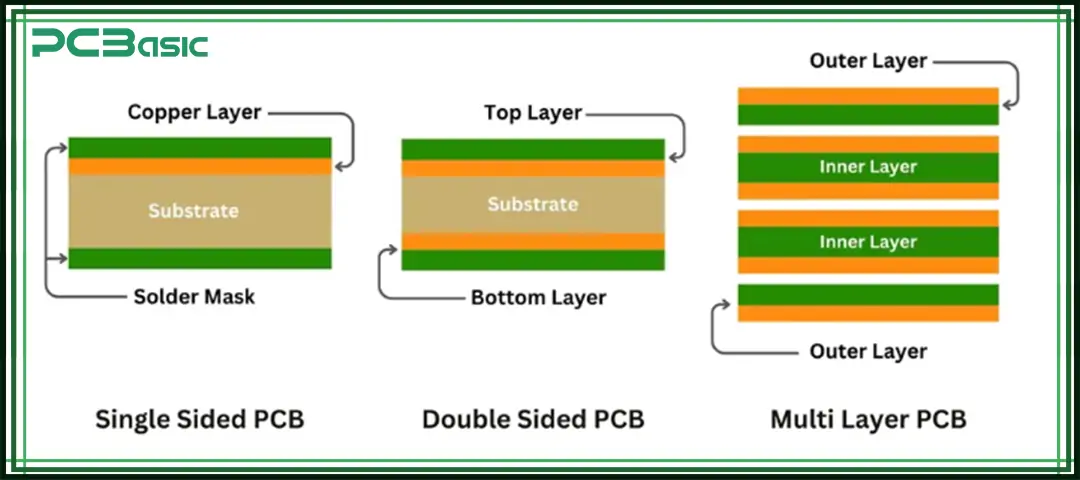

MCPCBs can be classified into various types based on the number of layers and structure to meet the heat dissipation and electrical requirements of different applications. The position of the metal core, the complexity of the lamination process, and the design of the heat transfer path will all affect the performance, cost and application range of the circuit board. From common single-layer MCPCBs used in LED lighting to complex multilayer MCPCBs applied in satellites and medical equipment, each type has its unique design features and advantages.

The table below provides a clear comparison of the main MCPCB types, including their layer count, structural features, and typical applications.

|

Type |

Layer Count |

Structural Features |

Typical Applications |

|

Single Layer MCPCB |

1 copper layer |

Copper circuit layer + dielectric + metal base |

LED lighting, relays, audio devices, sensors |

|

COB MCPCB (Chip-on-Board) |

Single layer with direct chip mounting |

Bare chips mounted directly on the metal base, no dielectric barrier, thermal conductivity >200 W/m·K |

High-power LEDs, automotive headlights, street lamps, horticultural lighting |

|

Double Layer MCPCB |

2 copper layers (same side) |

Two copper layers on one side of the substrate, requires complex lamination and hole filling |

Power modules, office automation equipment, amplifiers |

|

Double-Sided MCPCB |

2 copper layers (both sides) |

Copper traces on both sides of the metal core, connected with vias |

Industrial control, converters, UPS systems, dashboards |

|

Multilayer MCPCB |

≥3 layers |

Multiple conductive layers separated by a dielectric, with a central metal base |

Servers, satellites, nuclear detection systems, and medical equipment |

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

MCPCBs are widely used in various products that require strong heat dissipation:

The most common application of metal core PCBs is in LED products. The use of MCPCB LEDs can quickly dissipate heat, keep lights bright and extend their lifespan at the same time.

In the field of automotive electronics, metal core PCBs are widely used in power controllers, voltage regulators, ignition systems and electric vehicle drives. These applications have large currents and high heat generation, so metal core printed circuit boards can better ensure stability and reliability.

Whether it is a DC-DC converter or a solid-state relay, metal core PCBs can help the power system work stably for a long time. In these environments, whether it is a copper core PCB or an aluminum PCB, heat dissipation capacity is the key.

Common applications in consumer and industrial equipment include LCD backlighting, printers and medical monitoring equipment. Using metal core PCBs can make the device more durable and avoid damage due to overheating at the same time.

Metal core PCBs are also used in solar panels, photovoltaic systems and motion control systems. They can withstand high current operation and effectively dissipate heat, ensuring system stability.

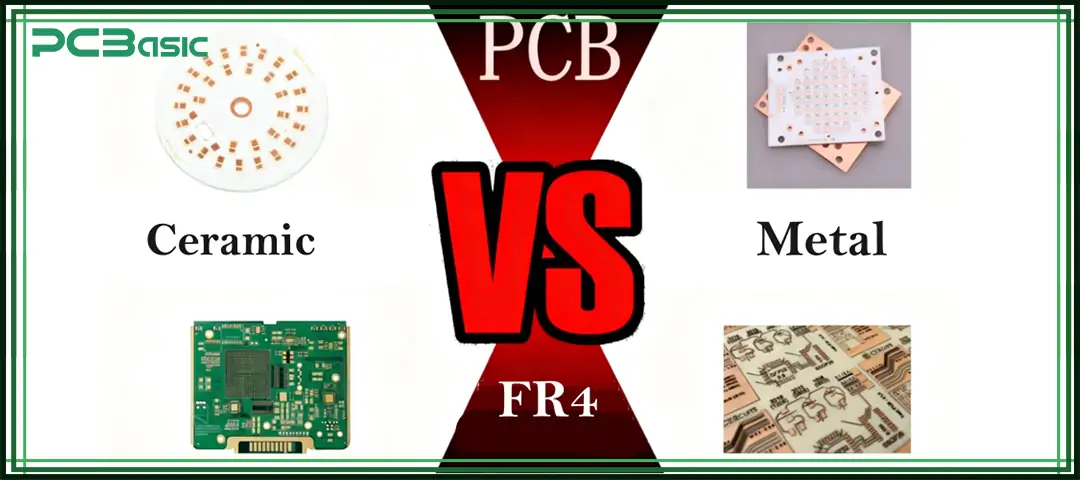

|

Feature |

FR4 PCB |

MCPCB |

Ceramic PCB |

|

Thermal Conductivity |

~0.3 W/m·K |

1–5 W/m·K |

20+ W/m·K |

|

Cost |

Low |

Medium |

High |

|

Mechanical Strength |

Good |

Excellent |

Brittle |

|

Applications |

General electronics |

LEDs, automotive, power |

Aerospace, RF, high power |

• FR4: inexpensive but poor at heat dissipation.

• MCPCB: balance of cost and performance.

• Ceramic PCB: superior thermal conductivity, but very expensive.

Thus, metal core PCBs are the preferred option for most high-power commercial and industrial electronics.

The MCPCB has become a key technology for heat dissipation management in modern electronic products. It enables the heat dissipation performance of the metal core printed circuit board to be 8-9 times faster than that of a standard FR4 circuit board by combining the copper or aluminum substrate, insulation layer and copper circuit layer together.

In fields such as LED lighting, automotive electronics, power electronics and renewable energy, metal core PCBs can ensure the efficient operation, greater reliability and extended service life of equipment. Although copper core PCBs have the best performance, aluminum metal core boards are more suitable for most applications because they are cheap and lightweight.

As equipment continues to become smaller and its performance improves, the demand for reliable MCPCB manufacturers will only increase. If you are looking for a professional metal core PCB manufacturer, be sure to choose a manufacturer that is experienced in the production of metal core PCBs and can meet industry standards, such as PCBasic.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.