Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Cold Solder: Causes, Problems, and How to Fix It

In electronic manufacturing, cold solder is a common and headache-inducing problem. Cold solder joints can make the solder unstable, affecting both mechanical strength and electrical connection. So, what is the cold solder joint? Why does it cause so many malfunctions? Understanding cold solder is essential for ensuring the quality of solder joints and avoiding costly maintenance and product rework.

In this guide, we will clarify the causes, manifestations, impacts, repair methods and preventive measures of cold solder.

Cold solder is a kind of soldering defect. It occurs during soldering when the solder is not completely melted or flowing and does not bond well with the pad or the surface of the component. In simple terms, the soldering temperature is not high enough, which causes the solder to fail to fully wet the pad, eventually forming a weak, unstable and easily broken connection.

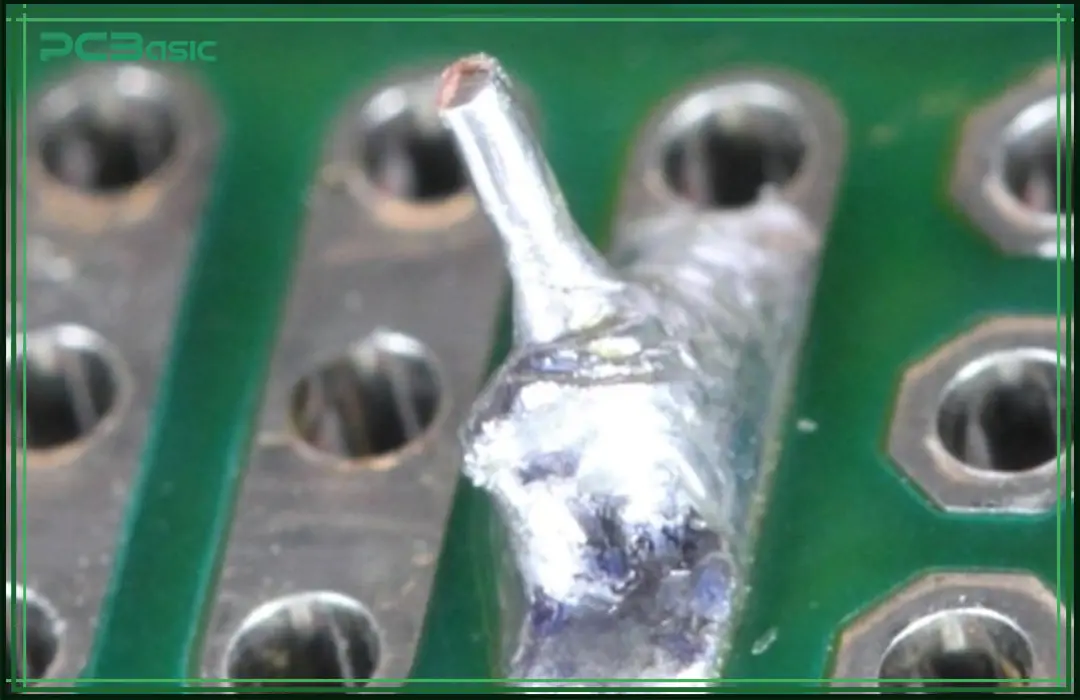

Compared with good solder joints, the appearance of cold solder joints is very different. The surface of normal joints is smooth and shiny. Cold solder joints are usually dull, granular or rough. Some cold solder joints may still function properly at the beginning, but they are prone to failure and disconnection when exposed to mechanical vibration, shock or temperature changes.

Cold solder joints are a type of soldering defect that occurs due to incomplete soldering. In simple terms, it means that the solder does not fully wet the surface of the solder pad during solder, resulting in the solder joint not being firmly bonded.

The core reason for cold solder joints is insufficient heating. Because the temperature was not high enough, the solder did not melt and flow completely, resulting in an unreliable connection. Such solder joints may experience intermittent on-off, sometimes conducting and sometimes not conducting. In severe cases, they may completely fail.

In electronic manufacturing, cold solder joints are regarded as one of the most serious bad solder joints. Especially in fields with extremely high-reliability requirements, such as aerospace, medical equipment and automotive electronics, cold solder joints can bring significant safety hazards and losses.

To prevent cold solder, it is necessary to first understand how it occurs. The following reasons are most likely to cause cold solder joints to appear:

• Insufficient Heating:

This is the most common cause. The temperature during soldering was not high enough, and the soldering equipment was not heated to the correct temperature. The solder doesn’t melt and flow completely, eventually forming a cold solder joint.

• Surface Contamination:

If there is dust, oil stains or oxide layers on the pins of components or the pads of PCBs, the solder cannot be properly wetted, which can easily lead to cold solder joints.

• Poor Soldering Technique:

During manual soldering, unstable operation, too short contact time, or moving components before the solder has cooled down can all lead to cold solder.

• Expired or Low-Quality Solder Paste:

Using expired solder paste or storing it poorly will reduce the soldering effect and make cold solder joints more likely to occur.

• Environmental Factors:

High environmental humidity, dust, or poor workplace conditions can all increase the risk of cold solder.

• Equipment Malfunction:

If the soldering equipment is not calibrated accurately or malfunctions, and the temperature is unstable, it will lead to cold soldering problems.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Cold solder joints can cause many serious problems and the repair cost is very high:

In terms of electrical performance, the cold solder joints may still be able to work normally at the beginning. However, due to poor conduct performance, intermittent on-off problems are prone to occur after a period of use, and eventually, it will completely fail, causing equipment failure. When the cold soldering problem is particularly severe, the connection will be completely disconnected, the electronic equipment will be unable to continue working, and may even be completely paralyzed.

As mechanical properties, the cold solder joints themselves are very weak. If the equipment is subjected to mechanical stress, vibration or temperature changes, the solder joints are easy to crack or break, causing physical damage.

From a maintenance perspective, it is not only time-consuming and laborious to identify and repair these defective solder joints after the product is fully assembled, but also the repair cost is extremely high.

For product reliability, especially in industries with extremely high-safety requirements such as medical equipment and aerospace, cold soldering may directly lead to serious equipment failures, and even cause legal disputes and huge economic losses.

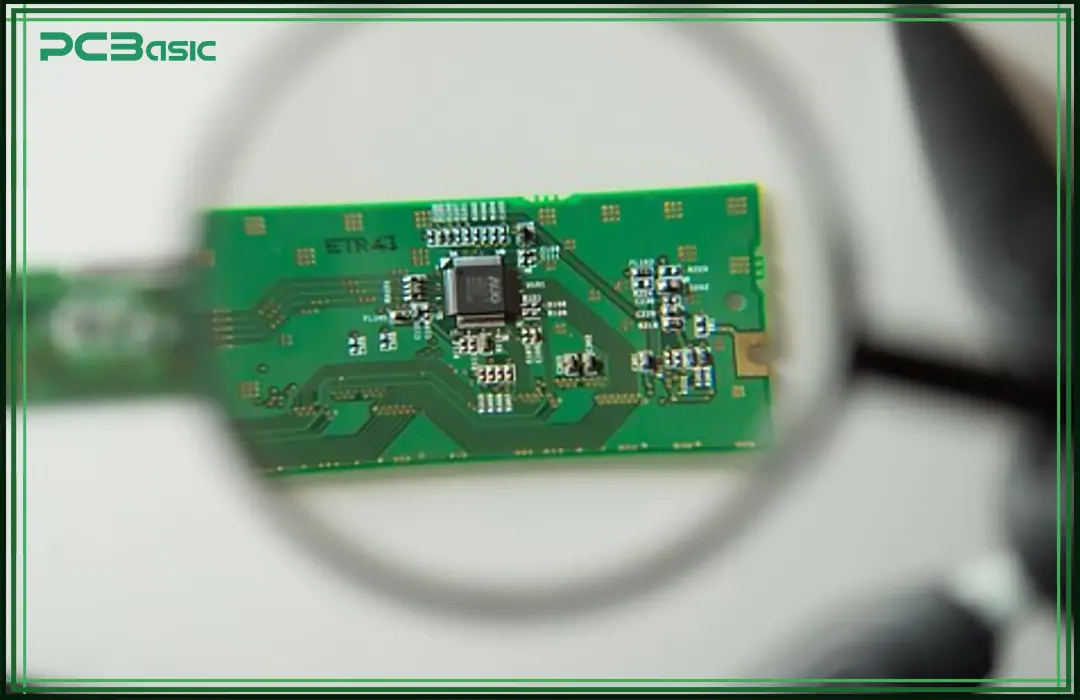

Early detection of cold solder joints is of great significance for quality control. If problems can be detected at an early stage, the cost of rework can be greatly reduced, and the failure of finished products can be avoided.

During visual inspection, cold solder joints usually have some obvious appearance features. The surface of the solder joints usually appears dull and lacks luster and sometimes presents a granular or rough texture. The solder distribution is uneven, the wetting is not in place, and it looks incomplete. Some cold solder joints may also have small cracks or pores inside. Solder sometimes accumulates into irregular shapes, and the solder balls may also deform.

In terms of functional performance, equipment with cold solder joints often experiences some electrical abnormalities. Intermittent power outages may occur, signal transmission may become unstable or distorted, and sometimes, the system may suddenly experience random malfunctions.

In addition to visual inspection and functional performance, some professional methods can also be used to detect cold solder joints. Automatic optical inspection (AOI) can quickly detect abnormalities on the surface of solder joints. X-ray inspection can detect hidden defects inside complex packages such as BGA. Continuity testing can confirm whether the electrical connection of the solder joint is complete. Functional testing, on the other hand, is to comprehensively assess whether the entire system is working stably under actual operating conditions.

If cold solder joints can be detected early, they are generally repairable. Timely repair can prevent more serious problems from occurring in the equipment later.

The first step in repairing cold soldering is to remove the previous solder first. Bad solder can be thoroughly cleaned by using a desoldering pump or desoldering braid. This can prevent the bad solder from affecting the new soldering effect.

Next, the surfaces of the solder pads and component pins need to be cleaned thoroughly. It is necessary to remove the surface contaminants and oxide layers to ensure that the soldering surface is clean and tidy, which is conducive to the subsequent adhesion of the solder.

Then, apply some flux to the soldering area. Flux can help solder better wet the pads and pins, and at the same time, it can reduce oxidation during the soldering process and improve the soldering quality.

Finally, re-solder with an appropriate temperature and the correct soldering method to form a firm and reliable solder joint. Correct heating and operation can significantly reduce the risk of cold soldering recurring.

Preventing cold solder is always much easier than fixing it later. If you control the process well before and during soldering, you can greatly reduce the risk of cold solder joints.

First, you must use the correct temperature settings during soldering. Whether you use a soldering iron or a reflow oven, make sure the temperature is accurate. The soldering equipment should be calibrated regularly. This prevents low temperatures that can cause cold solder.

Preheating the components before soldering is also important. Preheating makes the whole soldering area heat up evenly. This helps the solder melt and flow properly and prevents cold solder joints.

The soldering surfaces must be clean. You need to remove oil, dust, and oxidation from component leads and PCB pads. If the surfaces are dirty, the solder cannot wet them properly, which leads to cold solder problems.

It is also important to use high-quality solder paste. You should always use fresh and well-stored solder paste. If the paste absorbs moisture, expires, or is stored badly, it can easily cause cold solder joints.

The environment must also be controlled. You need to keep the humidity and cleanliness at proper levels. Moisture and dust in the air can affect the soldering process and increase the chance of cold solder.

The skills of the operators are very important, too. You should train soldering staff regularly. Proper training helps workers use the correct soldering techniques and reduces mistakes that lead to cold solder.

Finally, always follow industry standards, such as IPC-A-610. These standards help control solder joint quality and make sure every joint is strong and reliable.

|

Comparison |

Cold Solder |

Dry Joint |

Voids / Blowholes |

|

Main Cause |

Not enough heat |

Surface contamination or oxidation |

Gas trapped inside solder |

|

Appearance |

Dull, rough, poor wetting |

Smooth but weak bonding |

Internal holes, surface looks normal |

|

Electrical Performance |

Easy open circuits or unstable connection |

Poor contact, high resistance |

Reduced conduction area |

|

Mechanical Strength |

Cracks or breaks easily |

May detach under stress |

Weakened joint strength |

|

Detection |

Visual and functional test |

Functional test |

X-ray inspection |

|

Severity |

High |

High |

High |

Cold solder may seem like a minor issue at first, but its consequences are extremely serious. Understanding what cold solder joints are and mastering the methods of identifying and repairing them is crucial for ensuring product quality and long-term reliability. By adhering to the correct cold soldering techniques, controlling the environment, using high-quality materials and complying with industry standards, manufacturers can significantly reduce the risks of cold soldering and other poor solder joints.

Avoiding cold solder means better products, fewer failures and higher customer satisfaction - these are the goals that all electronic manufacturers should pursue.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.