Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Surface Mount vs. Through Hole: What are the Differences

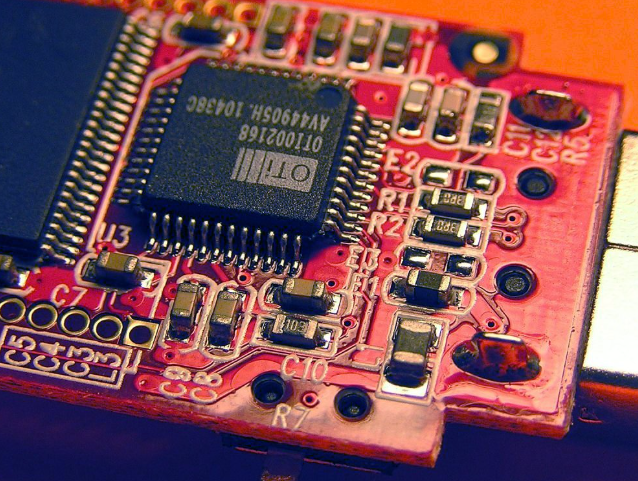

In the realm of electronics manufacturing, there is a comprehensive set of terminologies associated with surface-mount technology (SMT):

● SMA (Surface-Mount Assembly): This denotes constructing or assembling a circuit or module utilizing the surface-mount technology (SMT).

● SMC (Surface-Mount Components): Refers to the various electronic elements specifically designed for employment in surface-mount technology (SMT) applications.

● SMD (Surface-Mount Devices): Encompasses a wide spectrum of electronic components, spanning both active and passive components, along with electromechanical elements, all intended for integration into SMT-based circuits.

● SME (Surface-Mount Equipment): Denotes the specialized machinery and equipment tailored for the execution of Surface-Mount Technology (SMT) assembly processes.

● SMP (Surface Mount Packages): Signifies the diverse housing forms or casings designed to accommodate surface-mount devices (SMDs) within electronic systems.

● SMT (Surface-Mount Technology): Encompasses the entire gamut of practices and techniques employed in the assembly and mounting of electronic components onto circuit boards, constituting a cornerstone of contemporary electronic technology manufacturing processes.

● Surface Mount Resistors (SMD Resistors): These passive components regulate the flow of electrical current in a circuit, offering a multitude of resistance values and power ratings to suit various applications.

● Surface Mount Capacitors (SMD Capacitors): Capacitors responsible for storing and discharging electrical energy are available in various types, including ceramic, tantalum, and aluminum electrolytic variants.

● Surface Mount Inductors (SMD Inductors): These components store energy within magnetic fields and are predominantly deployed in filters and radio frequency (RF) circuits.

● Surface Mount Diodes (SMD Diodes): Diodes facilitating one-way current flow encompass standard diodes, Schottky diodes, and zener diodes within the realm of surface mount technology.

● Surface Mount Transistors (SMD Transistors): Transistors, pivotal semiconductor devices for amplification and switching, present an assortment of types such as NPN, PNP, N-channel, and P-channel MOSFETs in the SMD category.

● Surface Mount LEDs (SMD LEDs): Light-emitting diodes (LEDs), illuminating when electrical current traverses them, hold widespread usage in indicator lights and displays within the SMD category.

● Surface Mount Integrated Circuits (SMD ICs): These comprehensive electronic circuits, enclosed within a single package, may encompass microcontrollers, analog ICs, and digital ICs, among others.

● Surface Mount Connectors: Specifically designed for Surface Mount Technology (SMT) applications, these connectors establish electrical connections between PCBs or external devices.

● Surface Mount Switches: SMT switches fulfill various user interface and control functions. It comes in diverse types, such as push-button, tactile, and slide switches.

● Surface Mount Crystals and Oscillators: These components deliver precise timing and clock signals, crucial for the synchronization of electronic circuits.

● Surface Mount Transformers: SMT transformers play a vital role in power supplies and communication circuits by providing voltage transformation and isolation.

The dimensions and occupied volume of SMT electronic components significantly outshine their through-hole counterparts, often leading to reductions of 60% to 70%, with some components undergoing astonishing 90% size and volume reductions. Additionally, the weight of these components can be slashed by a substantial 60% to 90%.

SMT assembly not only excels in compactness but also offers an impressive safety density, reaching assembly densities of 5.5 to 20 solder joints per square centimeter when applying PCBs on both sides. The resulting SMT-assembled PCBs facilitate high-speed signal transmission due to their minimal circuit length and minimal delay. Furthermore, the resilience of SMT-assembled PCBs against vibrations and impacts enhances their suitability for ultra-high-speed electronic operations.

The absence of leads or the presence of short leads in SMT components naturally reduces the circuit's distributed parameters and mitigates radio frequency interference, culminating in favorable high-frequency characteristics.

SMT shines in automated production with standardized, serialized, and consistent welding conditions for chip components. This automation reduces component failures attributed to the soldering process, elevating overall reliability and enhancing production efficiency.

Efficiency improvements in production equipment and reduced packaging material consumption have driven down the packaging costs of most SMT components, rendering them more cost-effective than their through-hole technology (THT) counterparts of equivalent type and functionality. Consequently, SMT components are priced more competitively than THT components.

When mounting components onto PCBs, the need to bend, shape, or trim component leads is obviated, streamlining the entire process and augmenting production efficiency. The processing cost for achieving the same functional circuit is typically lower than that of through-hole interpolation, generally resulting in total production cost reductions ranging from 30% to 50%.

The implementation of a Surface-Mount Technology (SMT) PCB assembly line necessitates a substantial financial commitment due to the high cost associated with SMT equipment, including reflow ovens, pick and place machines, solder paste screen printers, and hot air SMD rework stations.

The inspection of SMT assemblies poses notable challenges, primarily because most surface-mount components are diminutive and boast numerous solder joints. Components with Ball Grid Array (BGA) packaging introduce further complexity, as their solder balls and joints are concealed beneath the component, making inspection a daunting task. Moreover, the equipment employed for SMT inspection comes with a hefty price tag.

SMD components are susceptible to damage, especially if mishandled or dropped. Their sensitivity to Electrostatic Discharge (ESD) necessitates specialized ESD products for safe handling and packaging. Typically, SMD components are managed within a controlled cleanroom environment to mitigate the risk of damage.

The production of SMT PCB prototypes or small-scale batches can be financially demanding. Moreover, the process involves technical intricacies that require a high level of expertise and training.

Surface-mount technology does not encompass all active and passive electronic components, resulting in constraints in terms of available power. Generally, SMD components tend to have lower power ratings than their through-hole counterparts.

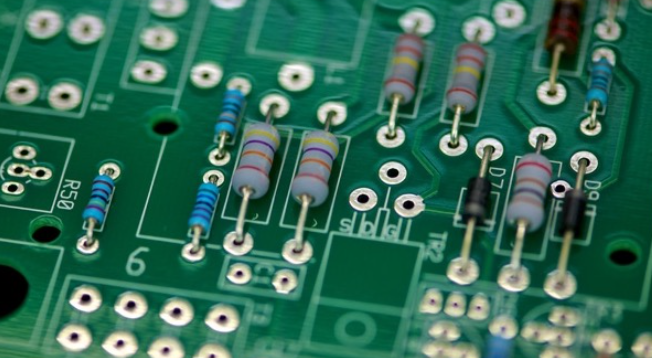

Notably, the through-hole technique, while facing a decline in popularity, has proven to be remarkably versatile in the era of SMT, offering various advantages and specialized applications. One standout attribute of through-hole technology is its inherent durability, and this durability is now often reinforced by the presence of annular rings, ensuring robust connections that withstand the test of time.

Through-hole technology (THT) PCB assembly boasts superior reliability compared to surface mount technology (SMT) assembly. Its heightened reliability stems from the physical anchoring of components to the board through holes and soldering, mitigating the risk of components becoming dislodged or detached during operation. Furthermore, THT components exhibit robustness in handling higher current and voltage levels, rendering them ideal for applications demanding substantial power.

THT PCB assemblies typically come with a lower price tag than their SMT counterparts. This cost advantage can be attributed to the reduced expenses associated with THT components and the simplified assembly process. The larger size of THT components not only makes them more manageable during assembly but also diminishes the likelihood of damage, ultimately leading to cost savings. Additionally, their ease of sourcing and affordability in the market contribute to cost-effectiveness.

THT PCB assembly facilitates straightforward repairs and component replacements. The through-hole design simplifies the identification and exchange of faulty components, as well as the repair of damaged wiring and through-holes. Furthermore, THT components can be easily extracted and replaced using a soldering iron, eliminating the need for specialized equipment.

Through-hole technology PCBA suffers from a limitation in component density. It arises from the fact that components are positioned on one side of the board, with their leads threaded through holes to the opposite side. Consequently, components must be spaced at wider intervals to prevent lead-to-lead contact. Consequently, THT PCBs tend to be bulkier and consume more physical space than surface mount technology (SMT).

THT PCB assembly is predominantly a manual endeavor demanding high skill and precision. Components are meticulously positioned on one side of the board, and their leads are then threaded through holes to the opposite side, followed by bending and soldering. This labor-intensive process is inherently time-consuming and susceptible to human errors. Furthermore, the manual nature of assembly complicates the prospects of automating THT PCB production, hindering efficiency gains.

There is a high risk of damaging components throughout the manual assembly process. The insertion of leads can result in bending or breakage, rendering components non-operational. Additionally, the soldering process, if not meticulously temperature-controlled, can expose components to excessive heat, leading to potential damage. These factors contribute to increased defect rates and reduced production yields.

In essence, SMT and THT continue to be the foundation upon which modern electronics are built, with each technology offering unique advantages that cater to a broad spectrum of applications and challenges. The dynamic interplay between these methodologies is a testament to the adaptability and innovation driving the electronic industry forward. Hopefully, you have now understood the difference between surface mount and through hole.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.