Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > > Phone Circuit Boards: A Comprehensive Guide

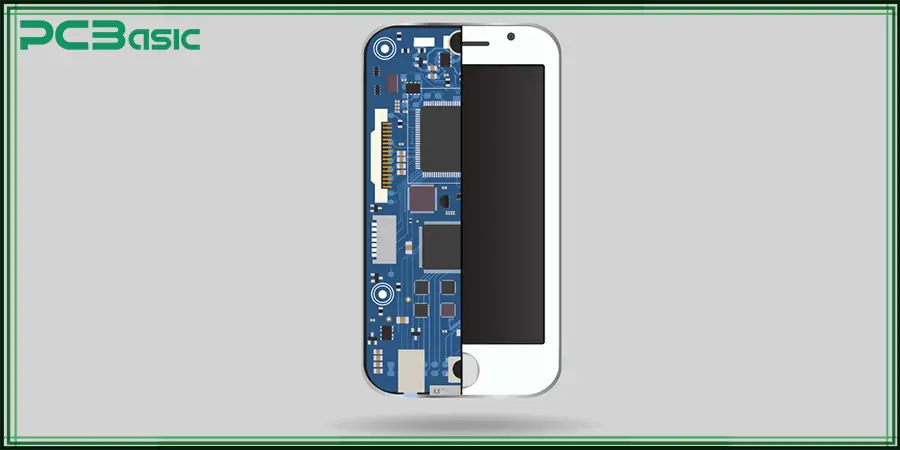

Nowadays, it is an era dominated by mobile Internet. It can be said that almost everyone has a mobile phone. And every swipe, click, call and connection of the mobile phone (whether you are using a telephone board with simple functions or a smart phone circuit board with a multilayer structure), all rely on a small but highly complex hardware core, the central nervous system of mobile electronic devices - the phone circuit board.

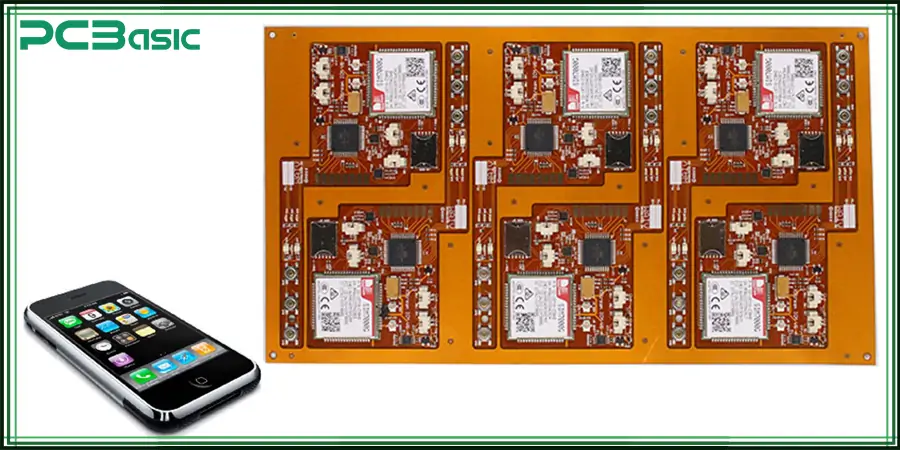

Phone circuit board, also known as telephone board or mobile PCB. It is not only a carrier of components, but also a high-precision signal routing platform, responsible for power regulation, data processing and wireless communication. It connects the processor, memory, battery, camera, and various functional modules, jointly supporting the operation of the smartphone. Next, this article will comprehensively analyze the circuit board in mobile phones, including its main components, classification of board types, key design points, and how to choose a reliable mobile PCB supplier.

The phone circuit board is the core platform of every mobile device, on which all electronic components are installed and interconnected. Its core is a multilayer printed circuit board (PCB), which connects and carries numerous electronic components through complex copper foil circuits to achieve the computing, communication, sensing and control functions of the entire mobile phone. It also plays numerous roles: signal transmission platform, power dispatching center, structural support core, heat management channel, etc.

In different usage contexts, people have different names for phone circuit boards. For example, telephone board is usually used in traditional feature phones or wireless communication devices; mobile phone board emphasizes its role as the control core of the entire machine; mobile PCB is a broad term, generally referring to printed circuit boards applied in various portable devices, covering different forms such as rigid boards, flexible boards, and rigid-flexible combination boards. As for the smartphone circuit board, it is the high-density Interconnect (HDI) PCB adopted in the current mainstream high-end devices, usually with a structure of 6 to 12 layers. Although their names are slightly different, they essentially refer to the same hardware.

The types of phone circuit boards are also diverse. According to the design requirements, performance specifications and space limitations of mobile phones, different types of mobile PCB boards have emerged.

According to the different number of layers, phone circuit boards can be classified into three categories: single-layer, double-sided layer and multilayer.

Single-layer mobile PCB board contains only one layer of copper foil wiring layer and has a simple structure. It is often used in feature phones or low-cost electronic devices and is suitable for basic signal transmission and simple control functions.

The double-sided cell phone circuit board has copper layers on both the upper and lower sides, supporting double-sided wiring and component installation. Compared with single-layer boards, double-layer phone boards have higher wiring density and functional expansion capabilities. It is often applied to mid-to-low-end smart phones.

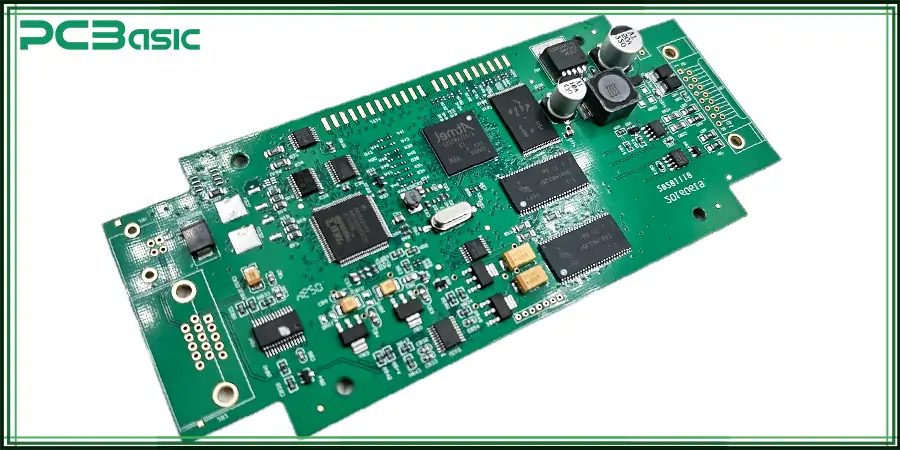

The multilayer phone circuit board is composed of more than three layers of copper and insulating layers stacked together. This type of phone circuit board supports complex high-speed signal transmission, power management and ground isolation.

Rigid phone boards are currently one of the most commonly used types of mobile phones. It adopts hard materials like FR-4, with a stable structure and suitable for the installation of high-density components. Especially in the processor and core chip areas, rigid PCBs can provide good support and reliability.

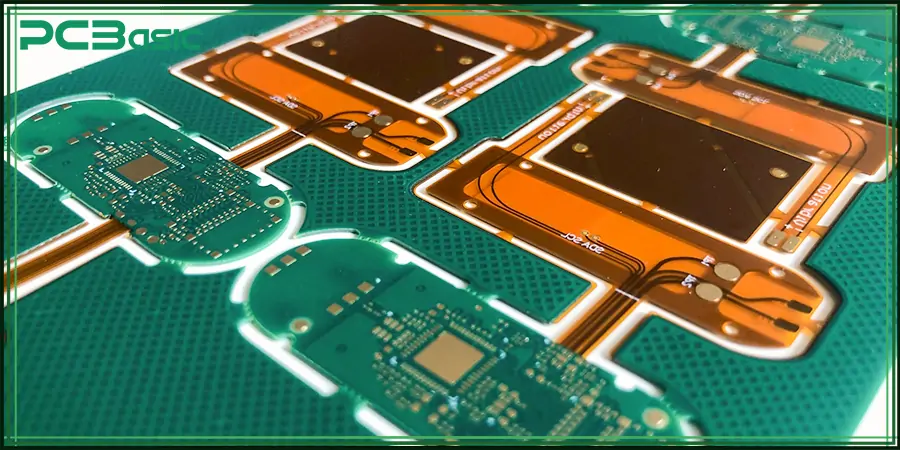

Flexible circuit boards are made of flexible materials such as polyimide. This type of mobile phone circuit board can be bent and folded in a limited space, and has advantages such as shock resistance and space-saving, but its design and manufacturing costs are relatively high. It is often used in camera modules, side fingerprints, the hinge part of foldable phones, etc.

The rigid-flex phone board not only possesses the structural strength of a rigid board, but also can be flexibly wired. It is an important structural solution for modern high-end smartphones. It is commonly seen in modules that need to be folded, rotated or highly integrated, such as battery and camera areas, etc.

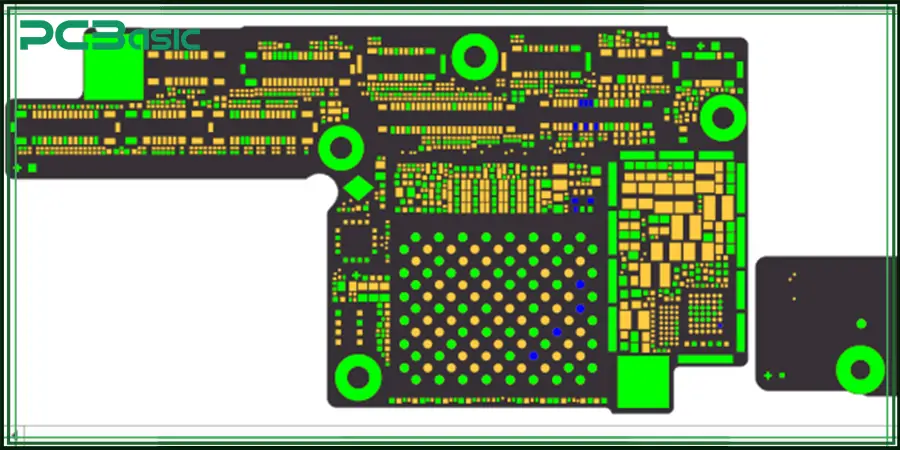

HDI boards are the preferred choice for high-performance mobile PCBs. This kind of board features smaller pads, finer wiring and higher wiring density. It is suitable for application scenarios with high-speed data transmission and high requirements for signal integrity, such as 5G, AI mobile phones, and other high-end smartphone circuit boards.

Metal substrates with aluminum or copper as the core can effectively enhance heat dissipation capacity. It is often used in functional modules with severe local heating (such as LED flashlights and high-power amplifiers). Although it will not be used throughout the entire mobile phone circuit board, the metal core board can play a key role in some local areas.

|

Component Name |

Image |

Description |

|

Main Processing Units |

|

Includes CPU and GPU, responsible for system operations, graphics, and AI |

|

Memory Components |

|

RAM and Flash used for data storage and application execution |

|

Power Management ICs (PMICs) |

|

Regulate voltage, distribute power, and protect against surges or shorts |

|

Battery & Charging Interface |

|

Manages power flow between battery and board, supports fast charging |

|

RF Modules and Antennas |

|

Enable cellular, Wi-Fi, Bluetooth, and GPS communication |

|

SIM & MicroSD Interfaces |

|

Provide access to cellular networks and external storage |

|

I/O Controllers and Connectors |

|

Manage USB, audio, display, touch, and other external connections |

|

Sensors |

|

Includes accelerometers, gyroscopes, light and proximity sensors |

|

Camera Modules and ISP |

|

Support front/rear cameras and image signal processing |

Smartphones have become thinner, lighter and more powerful, and the complexity of the phone circuit board has also increased accordingly. In this case, a reasonable structural layout of the circuit board and circuit optimization are very crucial. Because if the design is improper, it may lead to abnormal functions of the mobile phone or frequent maintenance of the mobile phone circuit board and other problems.

The following lists several key elements that need to be focused on when designing the mobile PCB:

Ensure the integrity of the signal. For instance, signal paths such as USB, DDR, and high-speed RF must be precisely routed to ensure impedance continuity and reduce crosstalk and reflection. Therefore, when designing, attention should be paid to the matching of the spacing and length of the differential line pairs and the impedance control technology.

In the design, the power supply plane should be reasonably set to reduce voltage drop and optimize the grounding return path to prevent insufficient local power supply. Ensure that each device can obtain a stable and efficient power supply.

Adding a shielding layer, optimizing the grounding structure and component layout effectively enhances the anti-interference capability and meets the electromagnetic compatibility standards. Avoid integrating too many high-speed interfaces to prevent EMI problems from becoming prominent.

Reasonably design heat dissipation and extend battery life to prevent the phone board from experiencing performance degradation or damage due to overheating.

A reasonably designed mobile phone circuit board can not only reduce the hardware failure rate, but also improve maintainability and long-term user experience. Of course, apart from a reasonable design, choosing a reliable circuit board manufacturer and assembler is also very important.

PCBasic is an outstanding circuit board manufacturer and assembler in China. Since its establishment in 2011, it has a history of over 15 years in the manufacturing and assembly of circuit boards. If you need to manufacture and assemble high-quality phone circuit boards, please feel free to contact PCBasic. As a professional manufacturer of mobile PCB boards, PCBasic is committed to providing one-stop circuit board solutions for smartphones, feature phones, and wireless communication devices. PCBasic has:

1. Multilayer circuit board manufacturing capability

2. Customized motherboard design services for 5G, AI and miniaturized devices

3. A strict quality control system, covering AOI optical inspection, X-ray, flying probe testing and functional testing

4. Rapid prototyping and flexible delivery capabilities for the global market

5. ISO quality certification standards covering industries such as communications, consumer electronics, and OEM

Whether you need prototype samples, small-batch trial production or large-scale production, PCBasic is always oriented towards performance, stability and win-win cooperation.

From voice communication, App operation to data transmission and power consumption management, the cell phone circuit board is the technical core of every mobile phone. Whether it is developing the next generation of smartphones or repairing old devices, a thorough understanding of the design, structure, and maintenance process of mobile PCBs is the key to enhancing product quality and technological competitiveness. It is also crucial to choose a reliable manufacturer and assembler of phone circuit boards. We hope this guide has been helpful in understanding phone circuit boards and making informed decisions.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.