Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PCB Inspection: Methods, Standards, and Equipment

Today, with the rapid development of electronic manufacturing, PCB inspection is becoming increasingly important. Printed circuit boards (PCBs) are core components of electronic products, such as smartphones, medical devices, automotive electronics, and aviation systems. The performance of a PCB is directly related to the functionality, safety and stability of the entire product. Even a very small defect can lead to equipment failure, quality problems, and even cause serious economic losses.

To ensure the reliability of each PCB, manufacturers need to carry out strict PCB inspections during the design, production and assembly stages. By using reasonable PCB quality control methods, following industry standards, and being equipped with advanced circuit board inspection equipment, companies can effectively reduce defects, lower rework costs, and enhance the overall PCB quality, thereby strengthening customer trust and market competitiveness.

This blog will introduce several commonly used PCB quality control methods, explain relevant industry standards, list common PCB defects, and outline common PCB inspection equipment. After reading, you will understand how PCB inspection helps manufacturers improve reliability, reduce production risks, and continuously output high-quality printed circuit board inspection products.

Printed circuit board inspection (PCB inspection) refers to a series of processes used to check whether circuit boards have defects, structural issues or functional abnormalities. These checks can be applied to bare boards or fully assembled circuit boards. The main purpose of PCB inspection is to detect problems before they affect product performance or cause system failures.

At different production stages, PCB inspection can adopt various methods, such as manual visual inspection, automated optical inspection, or the use of advanced imaging technologies, such as PCB X-ray inspection. These methods can be used to check whether the electrical connections are normal, dimensions are accurate, component positions are correct, and whether the solder joints are firm.

For example, in circuit board inspection, we can find common issues such as component misalignment, poor solder joints or broken traces. Through these inspections, it can be ensured that the circuit board complies with industry standards and can work normally in actual use.

PCB inspection is essential for any product that demands high reliability. It helps detect problems early and avoids bigger losses. Here are the main reasons:

Errors may occur during the PCB production, component placement or soldering process. If PCB inspection is not carried out in time, it may lead to intermittent circuit failures, complete device malfunction, and even increased costs due to product recalls or rework.

By adopting the PCB quality control method, problems can be identified in advance, scrap can be reduced, the yield of qualified products can be improved, and the delivery speed can be accelerated.

Industries like aerospace, automotive and healthcare have very high requirements for product quality. To meet standards such as IPC-A-600 and IPC-A-610, strict PCB inspection must be carried out to check whether the soldering, dimensions and materials meet the standards.

In some critical equipment, such as pacemakers or airplanes, a minor PCB failure may lead to serious consequences. Continuous circuit board inspection can ensure that each circuit board is reliable and stable.

Many people think that PCB quality control increases time and cost. But in fact, they can reduce the risks of later repairs, warranty claims and failure risks. In the long run, they are even more cost-effective.

During the PCB manufacturing and assembly process, different circuit board inspection methods can be combined and used according to the complexity of the circuit board and the output. The following are several common and important inspection methods:

This is the most basic PCB inspection method. The operator observes the surface of the circuit board with the naked eye or a PCB microscope. They look for visible problems such as poor solder joints, misaligned components or broken traces. This method is low-cost and easy to operate, making it suitable for small-volume production or prototype testing. However, due to the reliance on manual judgment, errors are prone to occur, and it is impossible to detect invisible internal defects.

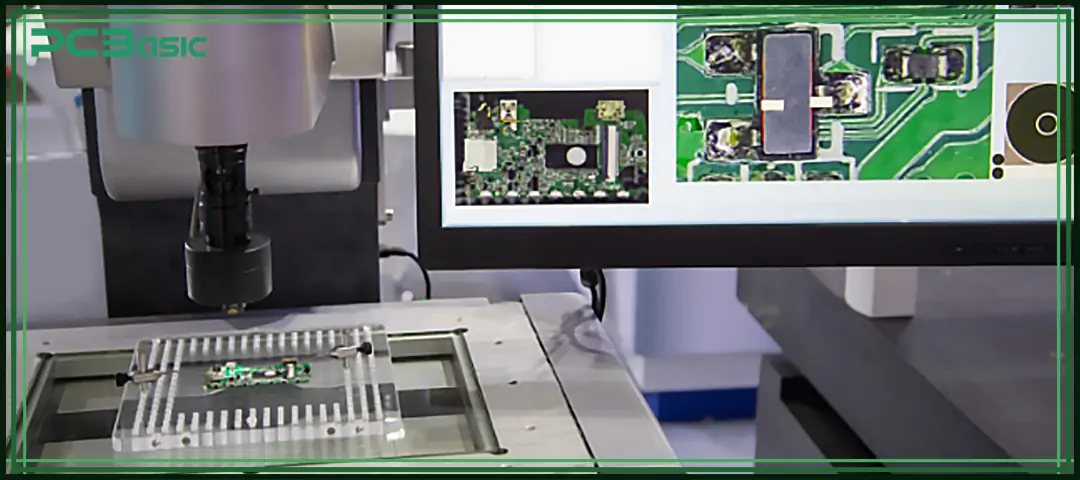

AOI automatically scans the circuit board through high-resolution cameras and specialized software and then compares it with the reference image. It can detect common issues such as missing components, misalignment, soldering issues or polarity errors. This inspection is an indispensable part of PCB quality control, particularly suitable for mass production, featuring high speed, high precision, and repeatability.

PCB X-ray inspection is used to check the hidden solder joints inside the circuit board, especially suitable for packages such as BGA, QFN, and LGA. It can detect structural problems such as solder voids, cold joints, layer misalignment or internal delamination. For complex multilayer PCBs or products that require extremely high reliability (such as medical devices and avionics), 3D X-ray systems can be used in combination to provide more accurate internal imaging.

ICT is a method of detecting component performance and circuit connectivity by using test probes to contact test points on circuit boards. It can verify whether resistors, capacitors, and diodes are normal and also detect short or open circuits. This method is suitable for mass production but requires the use of a customized test fixture as well as programming. Although the preparation time in the early stage is long, the detection efficiency is high, and it is one of the most widely used PCB quality control methods.

Functional testing is the final step carried out after the PCB assembly is completed. It powers up the board and simulates real operating conditions to verify whether the entire circuit works as expected. This kind of test does not focus on the quality of detailed soldering but rather on whether the entire board is working properly. It is an important step for judging whether the product is qualified.

The flying probe test uses automatically moving probes to test each circuit connection, without a custom fixture. This approach is suitable for prototypes, small-batch or frequently modified products, especially for the R&D stage. Although its testing speed is not as fast as that of ICT, it is highly flexible and cost-effective and can effectively complete conduction and insulation tests.

Hi-Pot testing detects whether the insulation performance is qualified by applying high voltage between different circuits on the circuit board. It is mainly used to confirm that there will be no leakage current or breakdown between circuits. This method is particularly applicable to high-voltage products, such as power boards and EV controllers and is an indispensable way of circuit board inspection in high-reliability industries.

|

Inspection Method |

Main Equipment |

Inspection Focus |

Suitable Scenarios |

Advantages |

Disadvantages |

|

Manual Visual Inspection (MVI) |

Naked eye, PCB microscope |

Visible defects: bad solder joints, misaligned components, broken traces |

Small-batch production, prototype testing |

Easy to operate, low cost |

Prone to human error, can’t detect internal defects |

|

Automated Optical Inspection (AOI) |

High-res cameras, image processing software |

Missing components, misalignment, solder defects, and polarity issues |

Mass production, automated SMT lines |

Fast, accurate, repeatable, scalable for volume |

Can’t detect internal layer or under-component defects |

|

X-Ray Inspection |

X-ray scanner, 3D X-ray system |

Hidden solder joints, voids, cold joints, layer misalignment, internal delamination |

Complex multilayer boards, high-reliability products (medical, aerospace) |

Reveals internal structure, essential for BGAs and dense packages |

High cost, complex operation |

|

In-Circuit Testing (ICT) |

Test probes, bed-of-nails fixture, programming system |

Electrical values (resistance, capacitance), component function, shorts/opens |

High-volume, standardized production |

High precision, automated, detects many faults in one run |

Long setup time, requires a custom fixture |

|

Functional Testing |

Power supply, signal/load simulators |

Overall board performance under real conditions |

Final verification, system-level testing |

Verifies actual use-case performance |

Can't locate the exact fault location |

|

Flying Probe Testing |

Automated flying probe tester |

Continuity and insulation without fixture |

Prototypes, small-batch, frequent changes |

No fixture required, cost-effective, flexible |

Slower than ICT, not ideal for high-volume production |

|

Hi-Pot Testing |

Hi-Pot tester, high-voltage source |

Insulation resistance, leakage, breakdown detection |

High-voltage boards (e.g. power supply, EV) |

Critical for safety, ensures insulation between circuits |

Not suitable for low-voltage applications, safety precautions needed |

By combining the use of the above methods, manufacturers can control the quality of circuit boards at multiple stages, achieve systematic PCB quality control, effectively improve the overall PCB quality, reduce defect rates, minimize rework and after-sales issues, and ensure stable product delivery.

When conducting PCB inspection, it is necessary to determine whether the circuit board is qualified in accordance with the industry-recognized standards. The two most commonly used standards are IPC-A-600 and IPC-A-610, corresponding respectively to the requirements of printed circuit board inspection at different stages.

IPC-A-600 is the standard used to inspect bare boards. It mainly focuses on the physical characteristics of the PCB, such as whether the overall dimensions meet the design requirements, whether the hole sizes are accurate, whether the spacing between traces is sufficient, and whether the safety distances are compliant. This standard is commonly applied during the early stage of printed circuit board inspection before components are mounted. By following this standard, manufacturers can eliminate structurally non-compliant PCBs early in the production process and avoid waste in later stages.

IPC-A-610 is the standard applied after component mounting. It is used to determine whether solder joints are full and reliable, whether the components are oriented correctly, and whether there are any issues such as cold solder joints, solder bridging, or misalignment. This standard is a very important part of later-stage PCB quality control to ensure that assembled circuit boards meet functional and safety requirements. It is especially indispensable in industries like medical and automotive, where high reliability is critical.

Here is a comparison table of IPC-A-600 and IPC-A-610 standards used in the circuit board inspection (circuit board inspection) process:

|

Item |

IPC-A-600 |

IPC-A-610 |

|

Applicable Stage |

Before component mounting (bare board stage) |

After component mounting (assembly stage) |

|

Inspection Focus |

Physical characteristics: dimensions, tolerances, hole sizes, trace spacing, safety distances |

Solder joint quality, component orientation, solder integrity, cold joints, bridging, misalignment |

|

Main Purpose |

Detect bare board defects early to prevent issues in later assembly processes |

Ensure assembly quality and that the board meets functional and safety requirements |

|

Role in PCB Inspection |

Used during early-stage printed circuit board inspection (printed circuit board inspection) |

Core part of late-stage PCB quality control (PCB quality control) |

|

Applicable Industries |

All industries involved in PCB manufacturing |

Especially important for high-reliability industries like medical, automotive, and aerospace |

|

Standard Objective |

Ensure the structure of the bare board meets design and process requirements |

Ensure assembled PCBs function properly and meet delivery standards |

These two standards are important documents that must be referred to during the circuit board inspection process. They can help manufacturers accurately judge the quality level of circuit boards at different stages, thereby ensuring the reliability and consistency of products in different application scenarios.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

During PCB manufacturing, whether manual or automated inspection methods are adopted, some typical defect problems are often encountered:

• Solder Bridges: When too much solder is applied, it connects two adjacent pads that should be separate, forming a solder bridge. This short circuit can cause the circuit to malfunction and may even damage components.

• Voids: These are gaps or bubbles inside the solder joints. They weaken the strength of the joint and can affect electrical connectivity, potentially leading to poor contact over time.

• Component Misalignment: When components are not placed accurately or are oriented incorrectly, it can lead to functional issues or prevent the circuit from operating.

• Lifted Pads: Pads may detach from the PCB substrate due to excessive heat or external force. This makes it difficult for components to be securely soldered, which affects the durability of the product.

• Insufficient Solder: If there is not enough solder, the connection between the component and the pad is weak. These weak joints may result in intermittent failures, especially in environments with vibration or heat.

• Cracked Traces: Routing lines can break or burn out during processing or use. This causes the circuit to lose connectivity and may cause certain functions to stop working.

These problems can all be detected through appropriate circuit board inspection methods. Commonly used inspection tools include automatic optical inspection (AOI), PCB microscope, and PCB X-ray systems, which can help detect detailed problems that are invisible to the naked eye, thereby improving the overall quality of PCBs.

In modern electronic manufacturing, PCB inspection is very crucial. It can not only detect defects at an early stage, but also help products comply with industry standards and enhance customer satisfaction. Reliable PCB quality control is the foundation for ensuring the long-term stability and reliability of products.

Whether using manual inspection, AOl, PCB X-ray or functional testing, these methods are all helping us confirm whether the circuit board is safe, stable and has good performance. With the continuous advancement of technology, PCB quality control methods are also becoming more advanced. Artificial intelligence and machine learning are enhancing the speed and accuracy of inspections.

In today's world, where connectivity and precision are essential, PCB inspection is not just a production step-it represents manufacturing quality and professional standards.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.