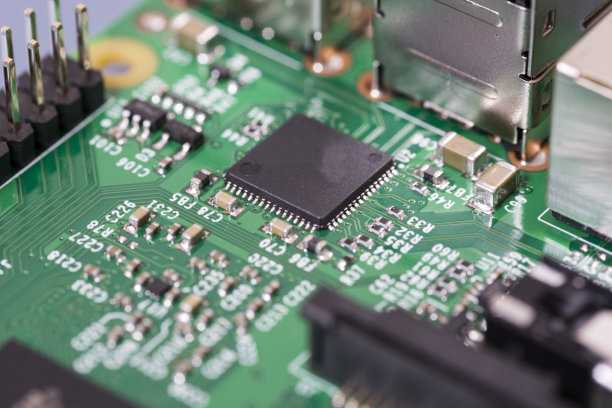

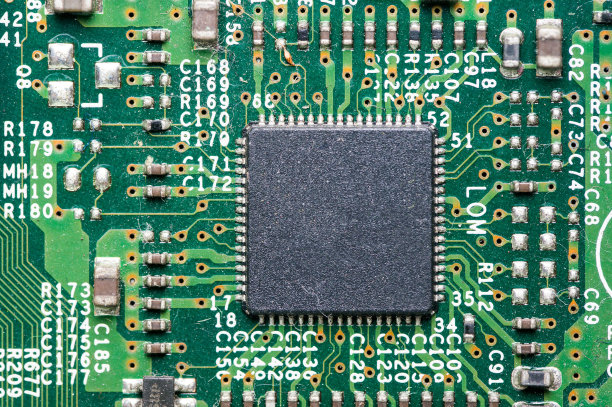

Have you noticed the color of the circuit board? Many people may be asking: Why are PCBs green? Actually, the circuit board colors we see are solder mask colors. The solder mask, or solder resist, can prevent the occurrence of wrong soldering of the components, delay the device's service life, and prevent the oxidation and corrosion of the device circuit. If you have a better understanding of electronic products, you will find that the PCB color is generally green. So why are PCBs green?

After reading this article, you will get an in-depth insight into the significance of choosing green circuit boards. Therefore, we shall cover three following questions:

● Why are circuit boards green?

● What are the applications of green PCBs?

● What are other colors available in PCB manufacturing?

On your request, PCBasic can manufacture PCBs in all colors, whether green, white, red, blue, or yellow. Subsequently, you can order bespoke or corporate color circuit boards.

What is the Green Circuit Board?

The green circuit board is a signature color similar to other boards in terms of performance and manufacturing process. This is the color that distinguishes it from the rest of the printed circuit boards.

On green PCBs, the green portion is actually the outer insulating layer of resin known as a solder mask with colored pigments. The solder mask is applied to the PCB board to protect the copper traces underneath from environmental factors (i.e., dust and moisture), oxidation, and possible short circuits.

A green PCB is manufactured using a substrate material, typically rigid laminate or flexible polyimide. Both materials provide essential insulation and mechanical strength to withstand harsh environments. Similarly, such PCBs have thin copper foils to create conductive pathways for a smooth transition of electrical current. The green mask goes through a mesh screen under the circuitry. The next process is curing PCB, where the subsequent panel comes under mesh. If you want to apply another color, you must first eliminate prior material.

Note: Remember that separate silkscreen equipment is crucial to applying each color.

The solder-resistant resin offers the following advantages:

● It doesn't allow solder bridges to form between IC pins

● Provides moisture resistance

● Minimizes short circuits in PCB assembly

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Applications of Green PCB

Due to its cost-efficiency and reliability, green PCBs are everywhere. Therefore, we have listed some prominent industries which use green circuit boards in different gadgets.

Electronics Industry:

Generally, there are two major electronics industries: consumer and electronics. Both must run their operations with this small component. In consumer electronics, the application of green PCBs is quite common in the following devices:

● Smartphones

● Laptops

● Tablets

● LEDs

Simultaneously, in industrial electronics, the use of green circuits is evident in the following equipment:

● Control Systems

● Manufacturing equipment

● Similarly, automation, where we need greater precision

Automotive Industry:

The automotive manufacturing industry uses green PCBs in engine control units, safety systems, and infotainment systems. Due to their computing capabilities, the demand for HDI PCBs has increased in modern hybrid cars. Similarly, PCBs are integral to displaying critical information to vehicle drivers or passengers in instrument clusters. Ultimately, it enhances the functionality and safety of both driver and vehicle.

Aerospace and Defense:

Green circuit boards are crucial in aircraft navigation systems, radar equipment, and communication. Subsequently, printed circuit boards ensure efficiency and safety during any operation. Simultaneously, PCB use, such as missile defense systems, is abundant in the military.

Medical Devices:

The green circuit board is used in medical devices like X-ray and MRI machines. Such circuit boards improve accuracy. Similarly, medical equipment manufacturers use PCBs in making pacemakers and neurostimulators. Therefore, the use of green PCBs in these devices enhances their reliability.

Renewable Energy:

Biodegradable substrate PCBs are making news in the electronics industry. Green PCBs are common in solar power inverters. These inverters are incredibly efficient in getting solar energy. Subsequently, these PCBs help in monitoring wind turbines. Therefore, we can easily optimize energy efficiency in terms of production.

Why are Circuit Boards Green?

This is mainly because the green solder mask process is the most mature and simple, and the green PCB board is also more environmentally friendly. In addition to green, circuit board colors can be white, yellow, red, blue, matte, and even chrysanthemum, purple, black, bright green, etc. White exists because we must use it to make lamps and lanterns. The use of other PCB colors is primarily to distinguish different product samples. In the entire stage of the company, from R&D to product landing, the color choice of circuit boards depends on the various uses of the PCB. The experiment PCB board color may be purple, the key PCB color will be red, and the internal PCB color of the computer will be black. So they are marked by color. Green solder mask ink is the oldest, cheapest, and most popular. So, it's not difficult to understand why PCB is usually green.

There are several reasons why PCBs are green:

1. In PCB processing, the production of electronic products includes board-making and post-filming. These processes have to go through the yellow light room, and the green PCB board has the best visual effect in the yellow light room;

2. Secondly, during SMT patch processing, the steps of tinning, patching, and AOI calibration all require optical positioning calibration. The green circuit board is more friendly when recognized by the instrument;

3. Part of the inspection process relies on worker observation (but now most of them use flying probe testing instead of labor), staring at the board under strong light. Green PCB board is friendly to the eyes;

4. Green PCBs are relatively environmentally friendly. No toxic gas will be released when the waste boards are recycled at high temperatures. Other PCB colors, such as blue and black, are doped with cobalt and carbon, respectively. Because they have weak electrical conductivity, there is a short circuit risk. In addition, colors like black, purple, and blue are so dark that they may increase the difficulty of the inspection and maintenance of the board, making the process hard to control.

Taking the black PCB as an example, the black PCB is most prone to problems in the production process and the ratio of raw materials. A little carelessness will cause noticeable color differences and lead to a high PCB defect rate. The traces of the black circuit board are not easy to distinguish, which will increase the difficulty of post-maintenance and debugging. Many PCB factories do not use black PCB very much. Even in the military industry and industrial control fields, products with extremely high-quality requirements are mainly made of green PCB substrates.

5. Green epoxy resin is more common and affordable than other colored resins. The green circuit board has become a standard in the manufacturing industry. The composition of economical materials has made green PCB a default choice for every PCB manufacturer.

Do PCBs Have to Be Green?

Basically, the color of a PCB doesn't impact its performance or functionality. PCB manufacturers offer various color options to meet the diverse needs of customers and industries. There is no restriction on color choice in making printed circuit boards, but manufacturers often prioritize green circuits due to their efficiency.

Generally, the choice of color depends on several factors, such as:

● Functionality

● Design requirements

● Branding

Let's read a short brief on green circuit board alternative colors:

1. White PCBs: White PCBs provide an aesthetic and clean look. They are often used when we need high contrast with components, labels, and solder markings.

2. Blue PCBs: Blue PCBs are standard in consumer electronics, where visual appeal matters greatly.

3. Black PCBs: Black PCBs have a higher consumption rate in equipment such as gaming PCs, high-end electronics, and motherboards.

4. Red PCBs: Red PCBs are suitable for customization and branding. They often serve to match a company's logo or product theme, making them distinctive and memorable.

5. Yellow PCBs: Yellow PCBs often show safety and warning signs. Furthermore, they can highlight critical zones and components.

Summary

While green PCB remains one of the most popular choices of buyers and manufacturers, we do not undermine the appeal of other colors in PCBs. Being a leading PCB manufacturer in China, we produce superior-quality circuit boards. Subsequently, believing in sustainability, we always look for ways to reduce environmental impact.

FAQs About Green PCB

1). Why are Motherboards Green?

Not all motherboards are green. Desktop computers and laptops usually use standard green solder masks. On the other hand, some companies prefer manufacturing heavy gaming devices with blackboards.

2). Why is the PCB Solder Mask Green?

Although various solder mask colors are available on the market, green solder mask ink is a more common and affordable material with high contrast, thereby reducing the production cost of PCB.

3). Does the Color of a Circuit Board Matter?

As mentioned above, the color of the circuit board doesn't impact the performance of any printed circuit board. PCB manufacturers use green circuit boards as a standard routine. Similarly, it helps in visual inspection during the assembly process.

4). What are Green PCBs Made of?

Green PCBs have multiple layers of materials like other circuit boards. A green circuit board often consists of the base material (substrate), copper foil, green solder mask, and silkscreen.

Looking for a PCB or PCBA quote? Contact us now.

About PCBasic

About PCBasic