Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Types of IC: A Comprehensive Guide

From smartphones and laptops to advanced industrial machinery, ICs are present in almost all electronic devices. They are core components of modern electronic devices. They can perform multiple functions, such as processing digital signals and amplifying analog signals, etc. With the advancement of technology, the demand for more compact, efficient and high-performance devices has made ICs even more important. A comprehensive and systematic understanding of ICs has also become even more important.

In this article, we will explore the definition, basic functions and types of ICs. We will also delve into and introduce the packaging and manufacturing processes of ICs. In addition, we will also discuss the integration of ICs in PCBs and their significance. By reading this guide, you will have a comprehensive understanding of ICs. Let's embark on a journey of IC knowledge!

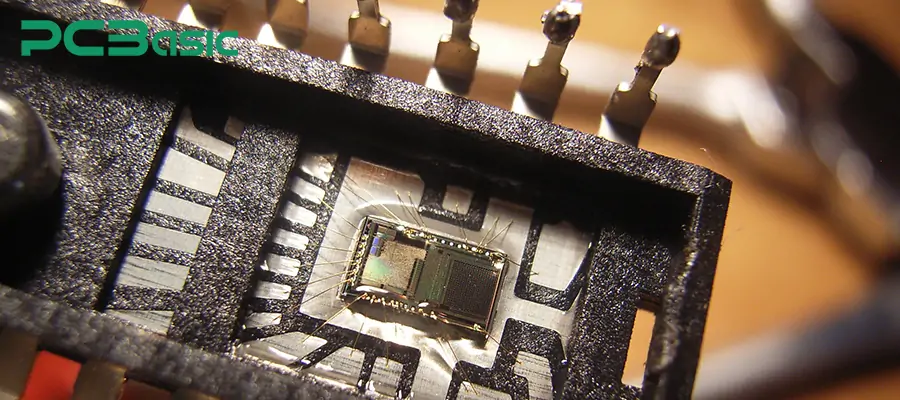

IC, the full name of which is integrated circuit, is a small electronic circuit that integrates multiple electronic components (such as transistors, resistors, and capacitors) into a single unit. These electronic components are all embedded in semiconductor materials (usually silicon). An IC, as a complete circuit, exists within a compact package and is capable of performing specific tasks in electronic devices.

In simple terms, an integrated circuit (IC) is a miniaturized circuit used to perform specific functions, such as signal amplification. Compact and cost-effective IC solutions have replaced bulky discrete components, bringing about a very thorough change to the electronics industry. It is widely used in various devices such as smartphones, computers, automobiles and medical equipment.

ICs perform various basic functions in electronic devices. They support different types of electronic systems and applications.

1. Signal Processing

ICs can amplify, modulate, filter or convert signals, whether they are analog or digital signals. It is widely applied in signal processing. For instance, in an audio amplifier, the IC amplifies the input signal to drive the speaker.

2. Data Processing

In computers and microcontrollers, ICs are responsible for data processing. For example, a microprocessor. It is a complex digital integrated circuit capable of performing a wide range of operations, such as arithmetic operations, logical operations and data storage. This type of integrated circuit is the core of computing systems and embedded devices.

3. Power Management

The IC can monitor voltage, current and power to ensure that the device operates normally under battery power or AC power supply conditions.

4. Storage Function

In many devices, integrated circuits are also used for storage. For instance, RAM (Random Access Memory) and ROM (Read-Only Memory) are used to store data and instructions in computers, smartphones and other devices. These ICs help manage data access and storage, ensuring rapid retrieval and writing of information.

5. Control System

The microcontroller can also be used to control specific tasks in household appliances, automation systems and robotics. These ICs process input signals from sensors and provide output to actuators, making them the brains of many embedded systems.

In conclusion, ICs perform multiple fundamental functions in electronic systems. These functions include but are not limited to signal processing, data processing, power management and storage functions, etc. Now, let's take a look at what types of ICs there are!

The classification methods of ICs are diverse. Below, we will distinguish them based on their functions, structures and manufacturing processes.

According to their functions, ICs can be classified into analog ICs, digital ICs, mixed-signal ICs and power ICs.

Analog IC

Analog ICs are used to process continuously changing signals, such as actual physical quantities like voltage, current or sound. Common applications of this type of IC include amplifiers, regulators, oscillators and analog filters, etc. In scenarios that require high-precision signal processing, such as audio equipment, signal conditioning, and sensor interfaces, analog ICs play a crucial role.

Digital IC

Digital ICs are used to process discrete (binary 0 and 1) signals. This type of IC is the core of computers, smartphones and most modern electronic products. For instance, microprocessors, microcontrollers, memory chips, logic gate circuits and timers all fall under the category of digital ICs. Digital ICs can perform complex operations, data storage and control decisions, and are an indispensable foundation for embedded systems and digital devices.

Mixed-Signal IC

Mixed-signal ICs integrate analog and digital circuits and can handle both continuous and discrete signals simultaneously. Typical examples include analog-to-digital converters (ADCs), digital-to-analog converters (DACs), and various sensor interface ICs. This type of IC is widely used in scenarios that require signal conversion, such as audio recording, communication systems, and instruments and meters.

Power IC

Power ICs are specifically designed for power management and distribution in electronic systems. Common types include power management ICs (PMics), voltage regulators, DC-DC converters and motor driver ICs. The power IC can ensure that each circuit section receives a stable and appropriate voltage and current.

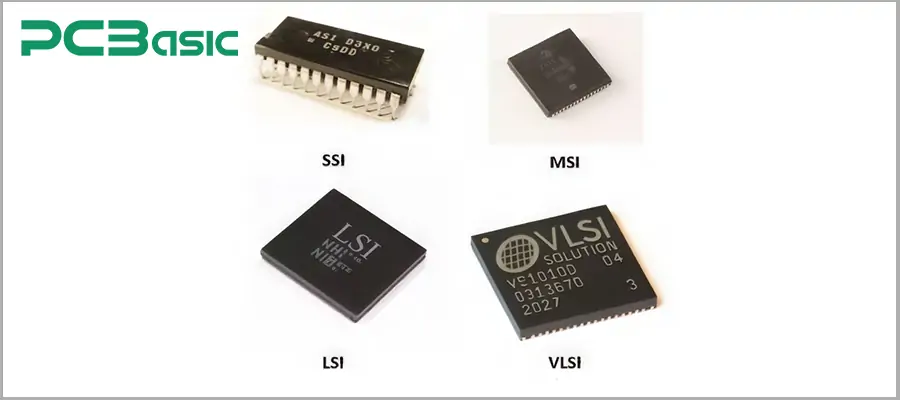

According to structure (integration degree), ICs can be classified as:

SSI: Small-scale integration refers to ICs with components ranging from 10 to 100. This type of IC is typically used to implement basic logical functions, such as simple AND gates, OR gates, and flip-flops. Small-scale integrated ICs are often used in basic logic control circuits, such as small household appliances and simple electronic devices.

MSI: Medium-scale integration is an IC that integrates 100 to several thousand components onto a single chip. They can perform more complex functions, such as adders, counters and encoders. Such ICs are typically used for general control and computing tasks.

LSI: Large-scale Integrated circuits consist of several thousand to tens of thousands of components, such as microprocessors. This type of IC is widely used in fields such as computers and communication equipment.

VLSI: Very large-scale integrated circuits can integrate hundreds of thousands or even millions of components. It can support high-performance CPUs, GPUs and system-on-chips (SoCs). This type of IC is a key technology in modern electronic devices.

According to the manufacturing process, ICs can be classified as:

|

Abbreviation |

Main Features & Applications |

|

Bipolar IC |

Built using bipolar junction transistors (BJT); high speed, strong drive capability; used in high-speed analog and TTL logic circuits. |

|

MOS IC |

Based on MOSFETs; low power consumption, high integration; widely used in digital circuits and CMOS chips. |

|

BiCMOS IC |

Combines the advantages of bipolar and MOS; high speed and low power; used in high-speed interfaces and RF circuits. |

|

CMOS, GaAs, etc. |

CMOS: ultra-low power, high integration, mainstream for microprocessors and memory; GaAs: high-frequency, high-speed, suitable for RF, radar, and satellite communications. |

By understanding the types of ICs, we can better choose the integrated circuits that suit our electronic projects. Next, we will introduce the types of IC packaging. Let's learn together how integrated circuits are implemented and protected on printed circuit boards (PCBs).

IC packaging is the process of enclosing ICs and providing the necessary electrical and mechanical connections to enable them to function properly. Packaging not only protects the ICs from environmental damage but also helps with heat dissipation. The main types of IC packaging are as follows. (If you want to know more detailed information about IC packages, please read this article: IC Package Types)

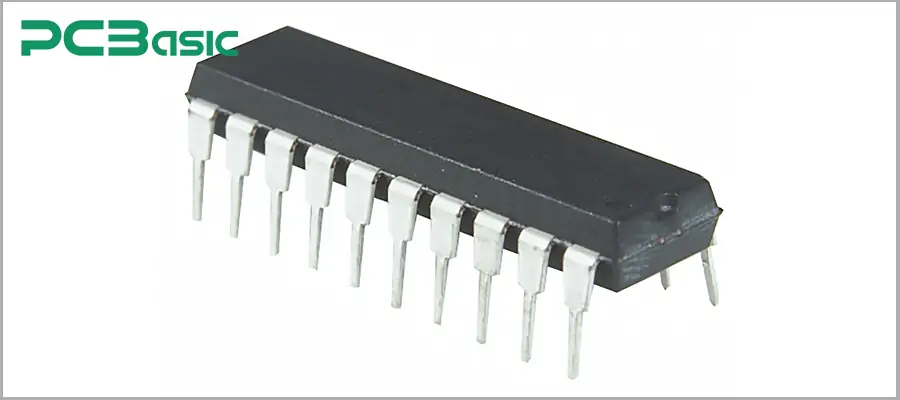

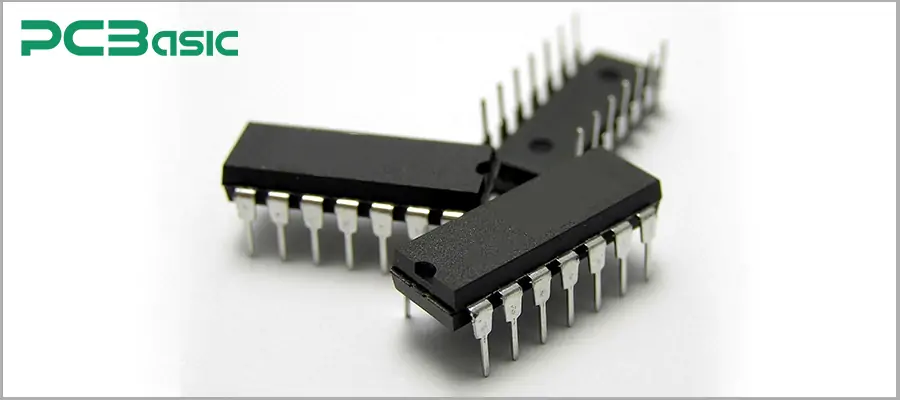

DIP is one of the oldest and most commonly used IC packages. This package has two rows of pins and can be directly inserted into the holes of the PCB. It is commonly found in basic electronic devices such as microcontrollers, logic gate circuits and amplifiers.

Advantages: Easy to handle, simple to weld, and widely applicable.

Disadvantages: Takes up a large space and not suitable for high-density applications.

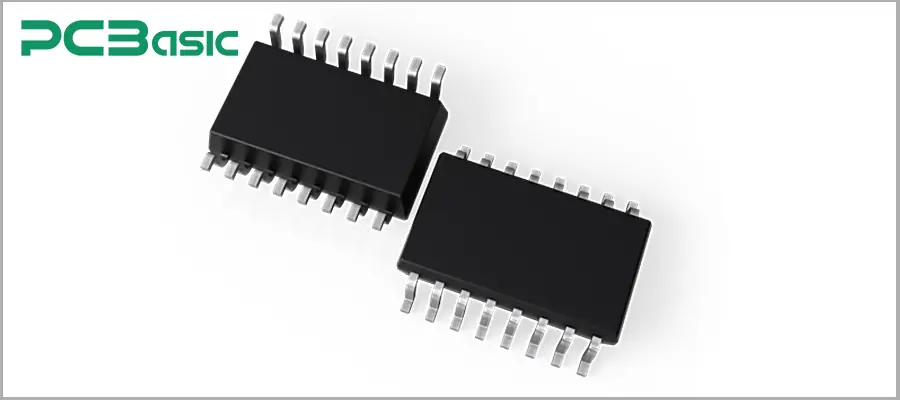

SMD is a type of package that allows ICs to be directly installed on the surface of a PCB instead of being inserted into holes. SMD is usually smaller than DIP. This type of packaging is very common in modern consumer electronics, automotive systems and high-frequency applications.

Advantages: Small size, high density, and better performance due to the reduction of lead inductance.

Disadvantages: It is rather difficult to handle during manual assembly and requires automated placement and soldering.

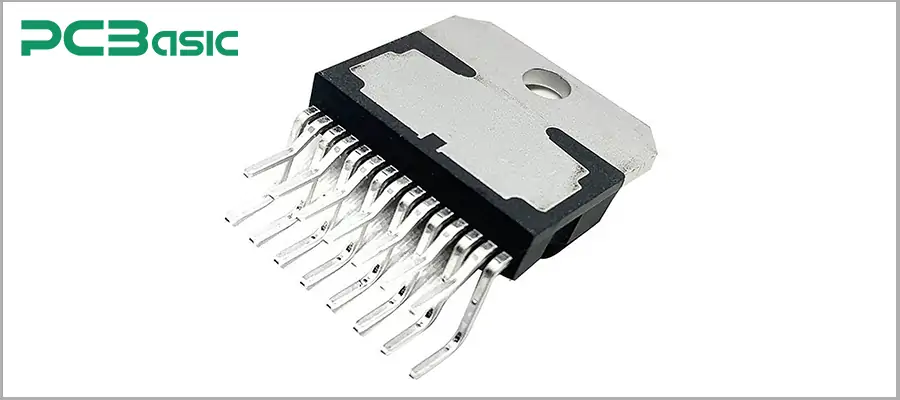

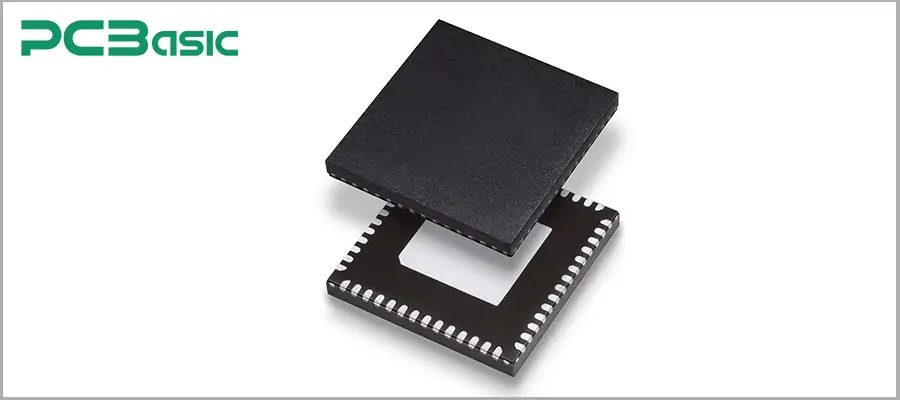

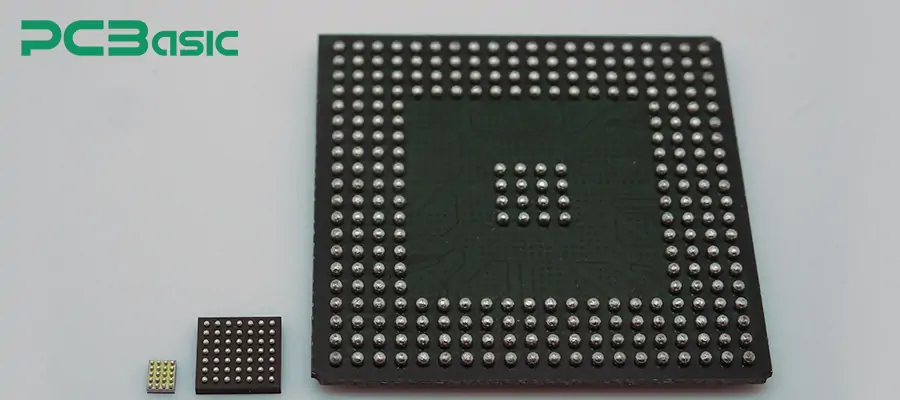

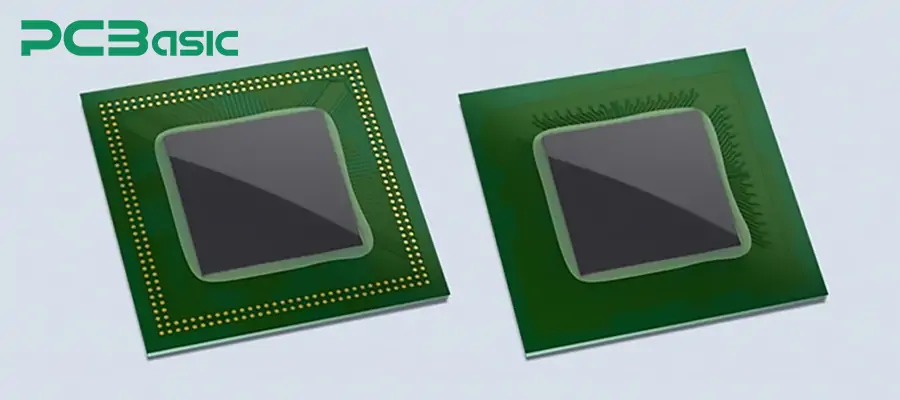

BGA is a surface mount package with rows of solder balls at the bottom connected to the PCB (these solder balls are its electrical connection points). BGA is widely used in high-performance devices such as microprocessors, memory chips and graphics processing units.

Advantages: High density, excellent thermal performance, and enhanced electrical performance.

Disadvantage: It requires precise assembly techniques and dedicated equipment.

QFP is a package with four sides, and each of the four sides of the package has pins. It is suitable for ICs that require more pins than the standard DIP. QFP packaging is widely used in microcontrollers, signal processors and network devices.

Advantages: A large number of pins, wide application, and excellent performance.

Disadvantage: It is more complex than DIP and requires careful soldering.

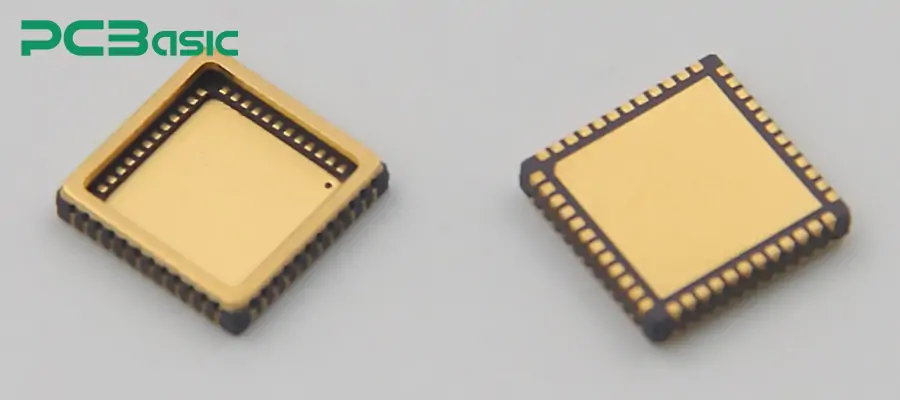

LCC is a surface mount package. There are no pins at the bottom of the package; instead, there are leads located beneath the package. LCC is used in components that require high performance and efficient space utilization, such as automobiles.

Advantages: Suitable for high-speed applications and efficient space utilization.

Disadvantage: Precise placement and soldering are required.

Flip-chip packaging is a packaging method that inverts the chip and directly connects it to the PCB. This method uses solder balls to connect ICs and PCBs and is widely applied in high-performance computing, telecommunications and mobile devices.

Advantages: Excellent electrical performance, high density, and better thermal management.

Disadvantages: The assembly process is complex and the cost is relatively high.

In addition to the six types of IC packages introduced above, there are many other types of packaging. Choosing the appropriate IC packaging type is crucial to the overall performance, reliability and manufacturing feasibility of the equipment.

As we mentioned earlier, IC packaging plays a crucial role in the integration of IC and PCB as well as the performance of the entire assembly process. Now, let's further explore the ICs in PCB assembly.

IC is an indispensable core component in PCB assembly. They can directly determine the function and performance of the circuit board. They are responsible for performing various tasks, such as signal processing, data storage and power management. Moreover, the selection of ICs will affect the overall design of the circuit board, the soldering process, thermal management and electrical connections. Different IC packaging types require different PCB designs. When choosing the appropriate IC package, we need to consider its power, the number of pins and the size. Overall, the role of IC in PCB assembly is extremely crucial. A reasonable selection of ICs can enhance the performance and reliability of circuit boards.

IC packaging will directly affect the layout, performance, assembly process of the PCB and the reliability of the final product. Different packaging types have a significant impact on the spatial layout and electrical performance of PCBs. The size of the package, the number of pins and their arrangement also determine the density of the PCB and the quality of signal transmission.

In addition, different packaging types also affect the welding and assembly processes. SMD packaging and BGA packaging are suitable for automated production and can enhance production efficiency. DIP packaging, on the other hand, usually requires through-hole soldering and is suitable for circuit boards with lower density.

Overall, the influence of IC packaging on PCB design covers multiple aspects. When choosing the packaging type, designers need to take a comprehensive consideration.

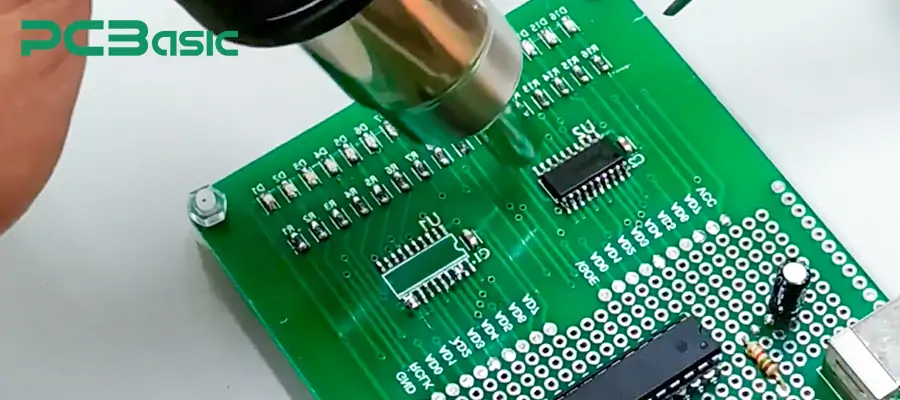

In PCB assembly, IC soldering is a crucial step to ensure the normal operation of the circuit board. We can choose different soldering methods according to the packaging type of the IC.

Surface mount soldering (SMT) is often used for ICs in SMD packaging. The IC is precisely soldered onto the surface of the PCB by using reflow soldering technology.

Through-hole soldering (THT) is often used for ICs in DIP packaging. The pins of the IC are inserted into the PCB vias through wave soldering.

After the IC is soldered onto the PCB, it must undergo strict testing to ensure its normal functionality. Common testing methods include:

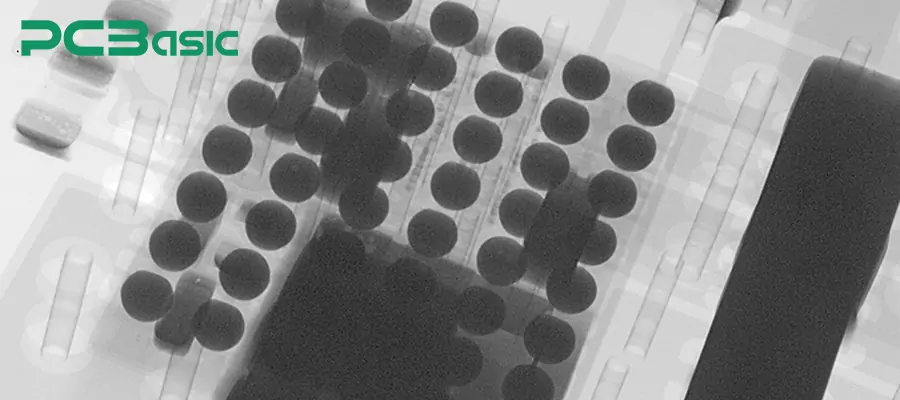

Soldering quality inspection: X-ray inspection is typically used for BGA packaging or other packaging types that are difficult to inspect by traditional methods. Inspect the solder joints through X-ray penetration, especially to check whether the solder balls of the BGA package are soldered in place.

Functional testing: It is used to verify whether the IC works as expected. Functional verification is usually carried out using automatic test equipment (ATE).

Thermal test: This test is used to ensure that high-power ICs do not overheat and that thermal management is sufficient.

Signal integrity test: It is used to ensure that the digital and analog signals processed by the IC are not distorted during operation.

In this article, we explore the crucial role of integrated circuits (ICs) in modern electronic devices. We also emphasized that understanding different types of ICs is crucial for choosing the right one. We also discussed the influence of IC packaging on PCB design. In addition, the correct soldering method and strict testing (such as functional testing and thermal testing) ensure the reliability and functionality of the IC.

In conclusion, a thorough understanding of IC types, packaging and assembly processes is crucial for manufacturing high-performance and reliable electronic devices.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.