Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > A Comprehensive Guide to PCB in AC | Air Conditioner PCB

In the current era when smart home appliances are widespread and energy-efficient cooling has become mainstream, the PCB (Printed Circuit Board) in an Air conditioner (AC) has become the "brain" and core component of every modern Air Conditioner.

Whether you are a user troubled by the malfunction of the AC Board (air conditioner control board) at home, a technician hoping to gain a deeper understanding of the structure and working principle of the AC PCB (air conditioner circuit board), or a DIY enthusiast full of curiosity about the internal electronic system of the air conditioner, it is very important to master the relevant knowledge of PCB in AC.

This article will systematically explain all aspects of PCB in AC in a straightforward and understandable way, including the full name of PCB in AC, core functions, common types, AC PCB Cost, design ideas, as well as common faults and troubleshooting methods. By reading this article, you can have a comprehensive and clear understanding of the AC Board before purchasing or replacing it, which will help you make the right choice and improve the user experience and maintenance efficiency of the air conditioner.

Let's start from the basics: the full form of PCB in AC, which is the printed circuit board in air conditioners, abbreviated as PCB. This PCB in AC is an electronic circuit board, which can be understood as the "brain" inside the air conditioner. Its main function is to manage all data and signals from user operations and sensors, control core components such as compressors and motors, and transfer and coordinate instructions among various sensors, thereby ensuring that each component in the air conditioning system can work efficiently and collaboratively. Without AC PCBs, even the most high-end and advanced air conditioning equipment cannot achieve intelligent operation and can only be a bunch of hardware components that do not respond.

PCB Full Form in AC

• PCB: Printed Circuit Board

The PCB in AC integrates a microcontroller, relays, connectors, and various sensors, thereby achieving intelligent control and data processing of all functions of the air conditioner.

In practical applications and maintenance scenarios, the PCB in AC is sometimes also referred to as AC Board, AC PCB or AC Control Board. No matter which name is used, these terms essentially point to the core electronic components in the same air conditioning system. It should be noted that the structure, function and interface design of the PCB in AC of different types and brands may vary, but their core role remains the same: to enable air conditioners to have the ability of intelligent control and automatic operation.

The PCB in AC, as the central control unit, undertakes the key control and management functions of the entire system, specifically including the following aspects:

The Microcontroller built into the PCB in AC can receive and parse various operation instructions from users, such as temperature setting, working mode switching and timer on/off. After parsing, these instructions will be converted into precise control signals and directly used to adjust the operating status of core components such as compressors, fans and solenoid valves, thereby achieving efficient and automated air conditioning control.

Modern AC PCBs usually integrate or are externally connected with multiple sensors, including temperature sensors, humidity sensors, and pressure sensors. Some high-end models also add air quality sensors. These sensors collect environmental and equipment operation data in real time. PCB in AC can automatically adjust the operation parameters based on this to ensure the best cooling and heating effect and energy-saving performance of the air conditioner.

The PCB in AC is responsible for controlling the start, stop and speed adjustment of the compressor and fan. For inverter air conditioners, the AC board can also output inverter signals to achieve stepless speed regulation, making the system run more smoothly, quietly and energy-efficiently.

The AC PCB uniformly manages the power supply of the entire machine and integrates overvoltage, short circuit, overcurrent and surge protection functions in the circuit, effectively preventing circuit damage caused by abnormal power supply and improving the safety and service life of the air conditioning system.

The PCB in AC directly drives the display and operation panel on the air conditioner. Whether it is a simple LED indicator light or a color LCD display screen, the AC PCB can provide real-time feedback on the operating status, fault information and parameter Settings of the air conditioner, facilitating users' monitoring and operation.

Smart air conditioners are usually equipped with AC PCBs that support functions such as Wi-Fi, Bluetooth or remote control, enabling remote control, data upload or seamless integration with smart home systems, further enhancing user experience and the level of intelligence.

Not all PCBS in AC are the same. According to the differences in the structure and function of air conditioners, the common types of AC PCBs mainly include the following, and each type has its unique role and corresponding AC PCB Cost:

|

AC PCB Type |

Main Function Description |

Installation Location |

Price Range (USD) |

|

Indoor Unit PCB |

Controls and manages indoor fan, temperature sensors, mode switching, and user interface. |

Indoor unit |

$15 ~ $55 |

|

Outdoor Unit PCB |

Controls compressor start/stop and operation, manages outdoor fan, power distribution, and protection circuits. |

Outdoor unit |

$20 ~ $70 |

|

Inverter Control PCB |

Drives and controls the inverter compressor, outputs variable frequency signals for energy-saving speed adjustment. |

Inverter-related area |

$40 ~ $140 |

|

Display PCB |

Drives display screen and indicators, shows temperature and operating status in real time. |

Near the display panel |

$8 ~ $28 |

|

Remote Receiver PCB |

Receives and decodes remote control signals to ensure accurate remote operation. |

Near the main control board |

$5 ~ $14 |

When purchasing or replacing air conditioning accessories, it is essential to confirm the specific type of AC PCB required (such as indoor unit PCB, outdoor unit PCB or inverter control PCB) to avoid installation or usage issues caused by model mismatch or functional incompatibility.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

The number of PCBs in an AC mainly depends on the type of air conditioner and the technical solution adopted.

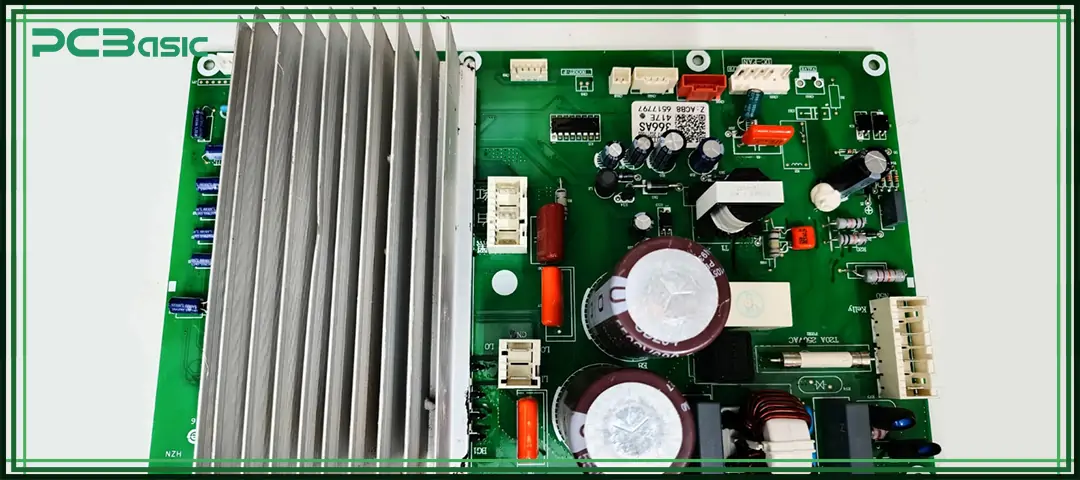

Generally speaking, a split air conditioner has at least two main AC PCBs: one is located on the indoor unit (indoor unit PCB), mainly responsible for controlling the indoor fan, temperature sensor and user interface. Another piece is located on the outdoor unit (outdoor unit PCB), mainly responsible for the compressor, outdoor fan and power management. If it is an inverter air conditioner, it will also be equipped with a dedicated inverter drive PCB to precisely adjust the rotational speed of the compressor, achieving energy conservation and constant temperature.

This type of air conditioner has a simpler structure, usually with only one PCB in AC, integrating all control functions, including the compressor, fan, mode switching and user interface, etc.

Large cassette or commercial air conditioners may be equipped with multiple AC boards to support more functions and more complex systems, such as multiple sensor networks, multi-fan management, or integrated control with building management systems.

Most modern split air conditioners usually have 2 to 3 PCBs in an AC, while simple-structured air conditioners such as window-type ones generally only have one main AC PCB. With the enhancement of air conditioning functions and the improvement of intelligence levels, more dedicated PCBs in ACs may be added inside the system to meet higher control and management requirements.

To design an AC PCB, one not only needs a foundation in electronic technology but also an understanding of the working principle of air conditioning systems. The following are the basic process and main considerations for AC PCB design:

Before designing an AC PCB, it is essential to clearly list all the functions that need to be implemented. For example, which Sensor Inputs, Relay Outputs, Communication interfaces, Display screens and various Protection functions are needed. When designing, the actual working environment should also be taken into consideration. The PCB in AC often needs to work under high temperature and high humidity conditions, so the selection of materials and structure must ensure long-term stable operation.

Select a highly reliable microcontroller or dedicated IC as the control core. It is recommended that the control signals of relays, compressors and fans be isolated by opto-isolation, which makes the electrical system safer. Each AC Board requires safety protection, such as fuses, varistors (MOV), and surge protection, which can effectively prevent circuit damage.

In the design of PCB in AC, the high-voltage and low-voltage circuits should be separated to avoid mutual interference. The output traces of the compressor and fan should be wired with thicker copper foil to ensure that they do not heat up easily when a large current passes through. For humid environments, it is recommended to apply conformal coating on the surface of the PCB, and at the same time ensure that there is sufficient electrical spacing in key areas to enhance moisture resistance and safety.

Before each AC PCB leaves the factory, it undergoes strict tests for high temperature, humidity and surge resistance to ensure normal operation in various extreme environments. The product must also comply with relevant safety standards such as IEC and UL. Only by passing the certification can PCB in AC be safely and legally put into market use.

When designing, a balance should be struck between the quality and cost of the AC PCB. Although cheap materials can save costs, low-quality boards are prone to problems and have high costs for later maintenance and replacement. When making a purchase, pay attention to the price of AC boards in the local market and select products with a high cost-performance ratio.

Choosing an experienced AC PCB manufacturer can guarantee quality. Automated testing and inspection should be adopted in the production process to enhance the consistency and reliability of AC PCBs, reduce malfunctions, and ensure the long-term stable operation of the products.

The PCB in AC is prone to faults after long periods of use. No matter how good the design is, these problems are very common.

The most common cause of AC PCB failure is power surges, especially in areas with unstable voltage. If the AC board does not have good surge protection, it can be easily damaged.

If the sealing is poor or the air humidity is too high, the PCB in AC can easily absorb moisture. The circuit board may become corroded and even short-circuited.

Component Failure

Common failed components on PCB in AC include capacitors, relays, and microcontrollers. If these parts go wrong, the board will not work properly.

If the air conditioner vibrates frequently or the assembly process is poor, over time the connectors on the PCB in AC can become loose, and solder joints may crack, leading to poor contact.

The AC board used in inverter air conditioners is more complex and sensitive to voltage and temperature changes. If these conditions fluctuate greatly, the inverter AC PCB is more likely to have problems, and the repair cost is higher.

• The air conditioner cannot start, or shuts down randomly

• Error codes appear on the display

• No response from the remote control

• Indoor or outdoor fan does not work

• Compressor fails to start

If the problem is minor, such as a blown fuse or capacitor, the AC PCB can be repaired. But if the board is burned or the failure is complex, it is usually recommended to replace it with a new AC PCB. Before replacing, it is recommended to compare the AC board price and AC PCB cost—sometimes, replacing the board is more cost-effective than multiple repairs.

The PCB in AC is not only a common electronic component, but also the core command center of the entire air conditioner. Whether you call it an AC Board, an AC PCB or a Control board, only when it works properly can the air conditioner cool or heat efficiently and ensure a comfortable indoor environment. When repairing, replacing or upgrading AC PCBs, it is essential to prioritize quality and compatibility rather than just looking at the lowest AC board price.

If you need professional PCB or PCBA manufacturing services for air conditioners, you can contact PCBasic. PCBasic can provide you with high-quality PCB manufacturing and assembly solutions, helping your air conditioning equipment operate more reliably.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.