Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > FPGA vs. ASIC – A Comprehensive Guide

In the field of digital electronics and computing, FPGA and ASIC are two core technologies. Whether in smartphones, data centers, or in artificial intelligence and communication devices, the presence of these two types of chips can be found everywhere. With the rapid development of the Internet of Things, 5G and high-performance computing, hardware systems have increasingly higher requirements for performance, flexibility and energy consumption.

The choice between FPGA and ASIC has become extremely important. In this article, we will conduct a systematic comparison between FPGA and ASIC. After reading this article, you will surely be able to better understand and apply these two types of technologies.

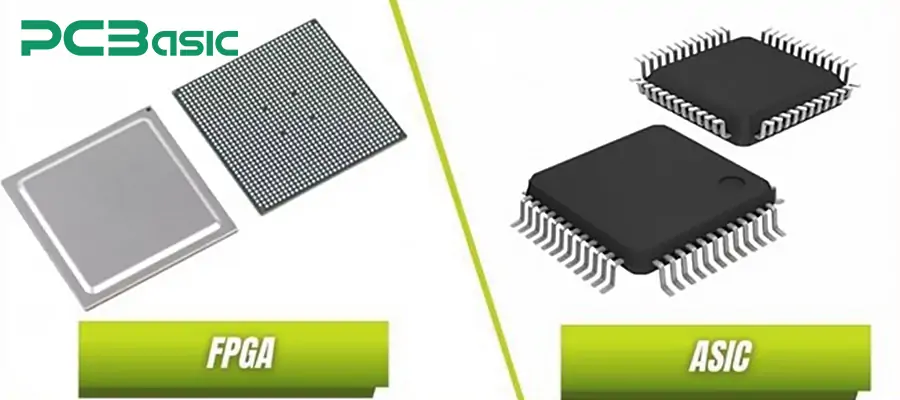

FPGA stands for Field Programmable Gate Array. It is an integrated circuit that can be programmed and reconfigured by users themselves after manufacturing. FPGA is highly flexible and suitable for rapid prototyping, hardware acceleration, and multiple iterations. Through FPGA programming, users can implement custom logic, test new algorithms, and update hardware functions at any time. FPGA is very popular in fields that require rapid adaptation and development, such as communication, artificial intelligence and scientific research.

The full name of ASIC is Application Specific Integrated Circuit. It is a dedicated chip customized for specific applications or functions. Unlike FPGAs, the functions of ASICs are fixed after manufacturing. ASIC computers and ASIC processors feature high efficiency, low power consumption and high performance, and are often used in Bitcoin mining, smartphones and consumer electronics.

If you want to gain a deeper understanding of the relevant knowledge of FPGA and ASIC, you are welcome to read this article.

Below, we have listed the comparisons of various aspects between FPGA and ASIC.

When comparing the cost structure of ASICs and FPGAs, we need to comprehensively consider the entire development process, production batch size and long-term business goals. Generally speaking, the initial cost of FPGA is relatively low, making it suitable for small-batch production, prototype development, and the early product stage.

In contrast, ASIC requires a large amount of upfront investment. The ASIC design process involves multiple costs such as chip design, verification and manufacturing preparation. These expenses are usually referred to as NRE costs. High upfront investment may become a threshold for start-ups or projects with limited budgets. However, as the production scale expands, the advantages of ASIC will become apparent. Once the initial development is completed, the unit price of ASICs will drop significantly, making them highly suitable for mass production.

The cost choice between FPGA and ASIC largely depends on the specific needs of users. For projects with small production volumes, frequent design changes, or the need for rapid prototyping, FPGAs have obvious advantages in terms of lower upfront costs and faster time to market. For projects that require mass production and can spread development costs over more products, ASICs can bring about long-term cost savings and lower unit prices.

When confronted with changes in market demand and project progress, the development cycle time of FPGAs and ASICs becomes a key factor. Generally speaking, the development cycle of FPGA is relatively short. Because FPGA is programmable. It can be modified and tested quickly at the hardware level. Designers can also quickly implement prototypes and iterate on them. These make FPGAs an ideal choice for projects that require rapid prototyping and quick adjustments.

In contrast, the development cycle of ASICs is relatively long. Because its design and manufacturing processes are complex. Typically, designing and manufacturing an ASIC processor involves multiple complex stages, including design, verification, layout, manufacturing, testing, etc. Each stage requires a great deal of time and resources. Moreover, in most cases, ASIC design requires a customized manufacturing process. In this way, the development time may last for several months or even longer. Moreover, any design change may lead to new verification and manufacturing cycles. Therefore, the development cycle of ASICs is often longer than that of FPGAs.

Overall, the choice of the development cycle for FPGAs and ASICs will depend on the urgency of the project and long-term requirements. For projects that require rapid development and frequent modifications, FPGA is a more flexible and efficient choice. For applications with a long product development stage, fixed functions and the need for long-term optimization, ASIC is a more suitable solution.

In the comparison of performance and power consumption efficiency between FPGA and ASIC, the advantages of ASIC are more obvious. Since ASICs are tailor-made for specific tasks, their computing power and resource utilization are specifically optimized during the design process. This enables ASICs to achieve higher speeds and lower power consumption when executing specific applications.

In contrast, the flexibility of FPGAs leads to their relatively weak performance and power consumption. Since FPGAs are programmable, they were not deeply optimized for specific tasks during the design process. This makes FPGAs often unable to achieve the speed and efficiency of ASICs when performing fixed functions. Meanwhile, the programmability of FPGA also brings additional power consumption. Because its hardware resources need to support a wider range of functions, its power consumption is usually high.

However, with the development of FPGA technology, FPGAs have improved in terms of performance and power consumption. The gap with ASIC can be partially bridged through dedicated hardware modules such as DSP units and embedded memory. In some applications, FPGAs can achieve performance levels similar to those of ASICs through optimized design and hardware acceleration, but they still struggle to match ASICs in terms of power consumption.

Overall, if your application has extremely high requirements for speed and power consumption and the tasks are relatively fixed, then ASIC will be a more suitable choice. For scenarios that require flexibility and programmability and applications with less stringent performance demands, FPGAs can offer a competitive solution.

In the comparison of design flexibility and upgradability between FPGA and ASIC, FPGA is superior. The greatest advantage of FPGA lies in its reprogrammability, which means it can be modified and updated after the product is put into use. This flexibility makes FPGAs highly suitable for projects with frequently changing requirements, especially in environments involving prototype development, rapid iteration, and continuous updates. Through reprogramming, FPGAs can continuously expand and optimize their functions throughout the product life cycle, avoiding the limitations brought by fixed hardware design.

In contrast, the design of ASICs is fixed. Once manufactured, its functions can no longer be changed. ASIC is highly optimized for specific tasks and is very suitable for applications with stable and long-term unchanging requirements. For instance, ASICs are widely used in mass-produced consumer electronic products because the functions of these products are relatively fixed and do not require frequent modifications and updates.

So, if your project needs to quickly adapt to new requirements, frequently update and customize, choosing an FPGA will offer more flexibility. If your project requirements are stable and do not require subsequent modifications, then ASIC would be a better choice.

FPGA can be reprogrammed according to different requirements and is widely used in fields such as test systems, signal processing, prototype development, communication and scientific research. Especially in scenarios where technological updates are rapid or where support for new protocols and algorithms is frequently required, FPGAs demonstrate significant advantages. By rapidly modifying hardware functions, FPGAs can offer great flexibility during the R&D and iteration processes, adapting to constantly changing demands.

ASICs are mainly applied in high-performance and high-yield demand fields such as consumer electronics, network devices, AI accelerators, and cryptocurrency mining. Because ASICs are tailor-made for specific tasks, they can offer extremely high efficiency, performance and energy efficiency in particular applications.

Overall, if your project requires high performance, fixed functions and is oriented towards large-scale production, choosing an ASIC would be more appropriate. If you need customized design and a quick response to technological changes, FPGA is a better choice.

ASIC offers enhanced security and intellectual property protection. Since the design of an ASIC is solidified within the chip, once its functions and structure are completed, they cannot be modified or replicated. This fixed design makes ASICs less likely to be reverse engineered or cracked, thus giving them a natural advantage in protecting intellectual property rights (IP).

Due to its programmability, the design of FPGA can be modified and updated on-site. Although this brings flexibility, it also makes it easier to be reverse engineered. The design files and configuration data of FPGAs are more easily copied or extracted, which may lead to risks of technology leakage and intellectual property rights. Therefore, although FPGA offers great flexibility in the development and iteration process, its security is relatively weak in terms of protecting intellectual property rights.

Overall, if you need to ensure that the technology is not cracked or stolen, it is recommended to choose ASIC. If higher flexibility and updatability are required and a certain level of security risk can be accepted, FPGA is a more suitable choice.

|

Comparison Aspect |

FPGA |

ASIC |

|

Initial Cost |

Low, no NRE fees |

High, significant NRE investment |

|

Unit Price |

Higher in low to medium volumes |

Lower in high-volume production |

|

Development Time |

Short, quick development |

Long, complex design, validation, and manufacturing |

|

Performance |

Moderate |

High |

|

Power Consumption |

Relatively high |

Low |

|

Design Flexibility |

Reprogrammable, upgradeable |

Fixed functionality, no upgrades |

|

Typical Applications |

Prototyping, research, communications, testing |

Consumer electronics, AI, mining, smartphones |

|

Manufacturing Complexity |

Simple, standard off-the-shelf components |

Complex, requires custom chip manufacturing |

|

Security/IP Protection |

Lower, more prone to reverse engineering |

Higher, fixed design reduces reverse engineering risk |

|

Post-Modification |

Easy to update and modify, highly adaptable |

Once manufactured, cannot be modified |

In the selection of FPGA and ASIC, the best solution depends on the requirements of your project. FPGA is flexible, fast to develop, and easy to modify later, making it suitable for research and development as well as prototyping. ASICs have high performance, low power consumption and good security, but they require a relatively high initial investment and a long development period. Whether choosing an FPGA or an ASIC, it is necessary to comprehensively consider budget, time, performance, power consumption, production scale and future scalability. Only through in-depth analysis and weighing can the most suitable choice be made.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

About PCBasic

About PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.