Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > PIR Sensor: A Complete Guide to Its Meaning, Working Principle, Design and Application

PIR Sensor, the full name of which is Passive Infrared Sensor. It is a very common electronic component in modern electronic products. For instance, in smart lighting (where the lights automatically turn on as soon as you enter a room), security alarms (instantly capturing any suspicious movement), and automatic doors, PIR motion sensors all play a crucial role. So, what is a PIR sensor? How does it work? How should it be designed and applied? Let's explore the knowledge related to PIR sensor together in this article! First of all, let's understand what a PIR sensor is.

The PIR sensor is an electronic component widely used in motion detection. It can sense changes in infrared radiation (that is, heat) from the human body, animals or other heat sources. It is often referred to as an infrared motion sensor, PIR detector or PIR motion sensor. Because it does not emit any signals by itself but only passively receives and measures infrared energy in the surrounding environment, it is also called a "passive" sensor.

Compared with active infrared sensors (which need to emit infrared light and detect reflections to sense objects), PIR motion sensors only need to detect changes in natural heat and do not emit any signals. This not only makes the PIR sensor more power-efficient, but also reduces false alarms caused by light reflection or environmental changes. In addition, PIR sensors have many other advantages.

1. PIR sensors can sensitively capture the movement signals of heat sources such as human bodies and animals. It has a low false alarm rate, strong anti-interference ability and can work stably in various environments.

2. The PIR sensor has a simple structure, requires few components and has a low production cost.

3. When movement occurs, the PIR sensor can respond in an extremely short time. This makes it highly suitable for automated scenarios that require real-time detection.

4. The PIR sensor is not affected by external factors such as light and dust, and can operate normally in the dark, strong light or complex environments.

PIR sensors are widely used in modern electronics and automation fields due to their many advantages. It can be found in various devices such as security alarms, automatic lighting, smart home devices, automatic doors, and vending machines. Every time you see the lights automatically turn on, it is very likely that the infrared motion sensor is working silently. So, what is PIR sensor’s working principle?

To understand PIR sensors’ working principle, we need to first recognize the scientific basis of infrared radiation, that is, all objects above absolute zero will continuously emit infrared rays. The PIR sensor can work precisely by taking advantage of this natural phenomenon. It determines whether there are people or animals moving within its detection range by sensing changes in infrared radiation in the environment.

Understanding this point well makes it very simple to understand the working principle of the PIR sensor. Its core is a special material with a pyroelectric effect that can sense infrared heat. The so-called pyroelectric effect refers to the fact that when materials absorb different infrared heat and their temperatures change, they will generate tiny electrical signals.

Most PIR motion sensors have two sensing elements placed side by side. When the ambient temperature is stable, the two components receive the same signal, and the output of the PIR sensor remains at a low level. When a heat source (such as a human body) moves within the sensing area, one component senses the temperature change before the other. In this way, the PIR detection sensor will output a change signal, thereby detecting the movement more accurately.

In addition to the core principle, the detection distance and sensing angle of the PIR motion sensor are also very important parameters. The detection distance of common PIR sensors is generally 5 to 12 meters, and the sensing angle is mostly between 90 and 120 degrees. It still depends on the design of the lens and the model of the module. In practical applications, choosing the appropriate PIR sensor module is also key to achieving precise and stable motion detection. Below, we will introduce the relevant content of the PIR sensor module.

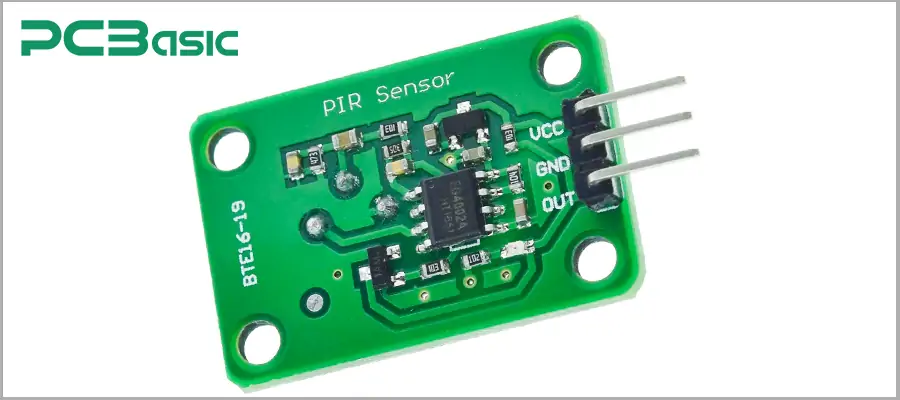

The PIR sensor module is a compact unit that integrates a passive infrared sensor with the corresponding electronic components. This design enables PIR motion sensors to be more conveniently applied in various electronic products and automation projects.

Each PIR sensor module typically contains the following core components:

|

Component |

Main Function |

Role & Features |

Remarks |

|

Passive Infrared Sensor |

Detects infrared radiation |

The core element of the module; senses heat changes caused by human/animal movement |

Usually a small metal can |

|

Amplification & Signal Processing Circuit |

Amplifies and filters signals |

Boosts weak signals and removes noise to ensure accurate motion detection |

Uses op-amps or dedicated ICs |

|

Comparator or Control IC |

Signal judgment and processing |

Determines if valid motion is detected and outputs a control command |

Improves module reliability |

|

Adjustable Potentiometer |

Sensitivity and delay adjustment |

Allows users to flexibly set detection range, sensitivity, and output delay |

Turn knob or screw-adjusted |

|

Output Interface |

Signal output |

Provides simple HIGH/LOW digital output for microcontrollers, relays, etc. |

Usually a 3-pin interface |

|

Power Input |

Provides working voltage |

Typically 3–5V DC, compatible with many control circuits |

Note polarity and voltage |

|

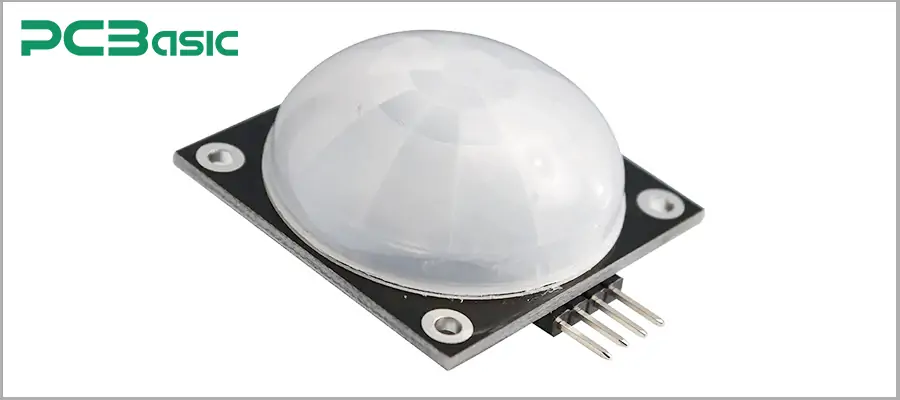

Fresnel Lens (in some modules) |

Focuses on infrared signals |

Enhances detection range and angle, allowing the PIR sensor to efficiently sense heat sources in the area |

Often a white plastic dome |

Some PIR sensor models are particularly popular due to their outstanding performance and ease of use. For instance, one of the most popular PIR sensor modules on the market is HC-SR501. This module integrates a standard PIR detection sensor and supports the adjustment of sensitivity and delay, as shown in the figure.

It is easy to wire and reliable in performance, and is widely used in Arduino projects, smart lighting and alarm systems.

The operating voltage of most PIR sensor modules is 3V to 5V DC, which is highly suitable for the requirements of various single-chip microcomputers and electronic systems. And its output signal is usually a digital output. That is, when motion is detected, the output pin of the PIR detection sensor will output a high level (generally 3.3V or 5V); If it is not detected, it will be at a low level. Some PIR sensor modules also support dual trigger mode or special output timing function. However, no matter how the functions are expanded, the basic power supply and output structures are similar in various PIR sensor modules.

Understanding the PIR sensor pins and their functions is very important for the correct and safe use of the module. PIR sensor modules typically adopt a simple three-pin interface.

VCC: Power pin, usually connected to 3 to 5V DC voltage, supplies power to the module.

GND: Ground pin, which needs to be connected to the negative terminal of the power supply or the system ground.

OUT: Signal output pin.

When the PIR motion sensor detects motion, the OUT outputs a high level (3.3V or 5V). When no detection is detected, output a low level (0V).

Most PIR detection sensor modules are equipped with two adjustable knobs (potentiometers) for:

1. Delay adjustment

Set the duration for which the module outputs a high-level signal after detecting motion. It can be freely adjusted from very short pulses to just a few seconds.

2. Sensitivity adjustment

Set the detection distance of the passive infrared sensor. By adjusting this knob, the module can be made to respond more sensitively or less sensitively to movement, thereby adapting to different environmental requirements.

These two adjustment functions enable the PIR motion sensor to adapt to different places and achieve the best detection effect.

Common pin arrangement diagram

The following is a typical pin distribution of PIR sensor modules such as HC-SR501:

Note: The pin sequence of modules of different models may vary slightly. Please be sure to read the module manual before use.

Mastering the PIR pinouts and functions of the PIR sensor module is the foundation for its correct use and integration. However, in practical applications, the performance of PIR modules not only depends on the components themselves, but is also significantly influenced by the PCB layout and design. A reasonable PCB design can effectively enhance the module's anti-interference ability, signal stability and overall detection effect. The following are the key points we have summarized regarding the PIR module in PCB design.

Passive infrared sensors are extremely sensitive to weak signals generated by movement and temperature changes. Electromagnetic interference can seriously affect their performance and accuracy. Therefore, good EMI shielding is of great significance for PIR sensors. It can help minimize noise and false triggering. We can:

1. Use a complete ground layer below the PIR sensor circuit to ensure a low-impedance path for the return current and help reduce EMI.

2. Consider installing a dedicated shielding cover such as a metal casing above the PIR motion sensor and its signal processing IC to block external interference.

3. Arrange decoupling capacitors near the power supply pins (VCC, GND) of the PIR sensor module to filter out high-frequency noise.

4. Separate the analog and digital ground and connect them only at a single point to reduce the ground loop interference of the infrared motion sensor.

5. Keep the sensitive PIR detector sensor signal traces away from noisy power lines, oscillators or high-speed digital circuits.

The optical lens in the PIR sensor module is used to focus the infrared signal onto the sensing element. The physical layout of lenses and sensors on the PCB will directly affect the PIR sensor sensitivity and the reliability of detection. So, we should:

1. Ensure that the lens is precisely aligned with the passive infrared sensor element to achieve accurate motion detection results.

2. On the PCB, physical isolation or barriers are used to separate the PIR motion sensor from other heat-generating components (such as voltage regulators) to avoid thermal interference.

3. Keep the sensor and its analog front end as far away from the digital switch components as possible to reduce electrical noise interference.

4. Avoid placing the PIR sensor near ventilation holes or air flow paths to prevent false alarms caused by temperature fluctuations.

When conducting compact design, lenses of appropriate types and positions should be selected based on the field of view requirements of the application scenarios to enhance the performance of PIR motion sensors.

Choosing a single-layer PCB or a multi-layer PCB for the PIR sensor module has an impact on both performance and production. We can:

1. When designing the multi-layer board, a special layer is reserved for the complete ground layer to support the PIR sensor pinout (pin distribution) and ensure stable operation.

2. Pay attention to the line width and spacing, and maintain sufficient intervals to prevent signal coupling and parasitic capacitance influence.

If the PIR motion sensor project has high performance requirements or will be applied in complex environments, it is recommended to give priority to multi-layer PCBS to achieve more stable passive infrared sensor performance.

PIR sensors feature a simple structure, low power consumption and high reliability, making them the preferred choice for various motion detection scenarios. After reading this article, you will understand the working principle of the PIR motion sensor - that is, how to passively detect infrared heat and convert it into an electrical signal. You can select the appropriate modules according to different scenarios and apply them. Scientifically and reasonably layout and design the PIR sensors on the PCB to achieve the best performance and stability. With the continuous growth of the demand for automation and intelligence, PIR sensors will play a more important role in future intelligent devices and systems.

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

About PCBasic

About PCBasic

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.