Are you new to the PCB industry and wondering how much PCB assembly costs? Then, fret not, as we will walk you through the process.

Knowing an accurate estimate of the PCB assembly is crucial since it helps you create a budget for your PCB project. Moreover, understanding it beforehand can aid in cutting expenses short.

So, come along as we discuss the data-driven discussions and peel back the layers of PCB assembly cost. Let's dive into it.

How Much Does PCB Assembly Cost?

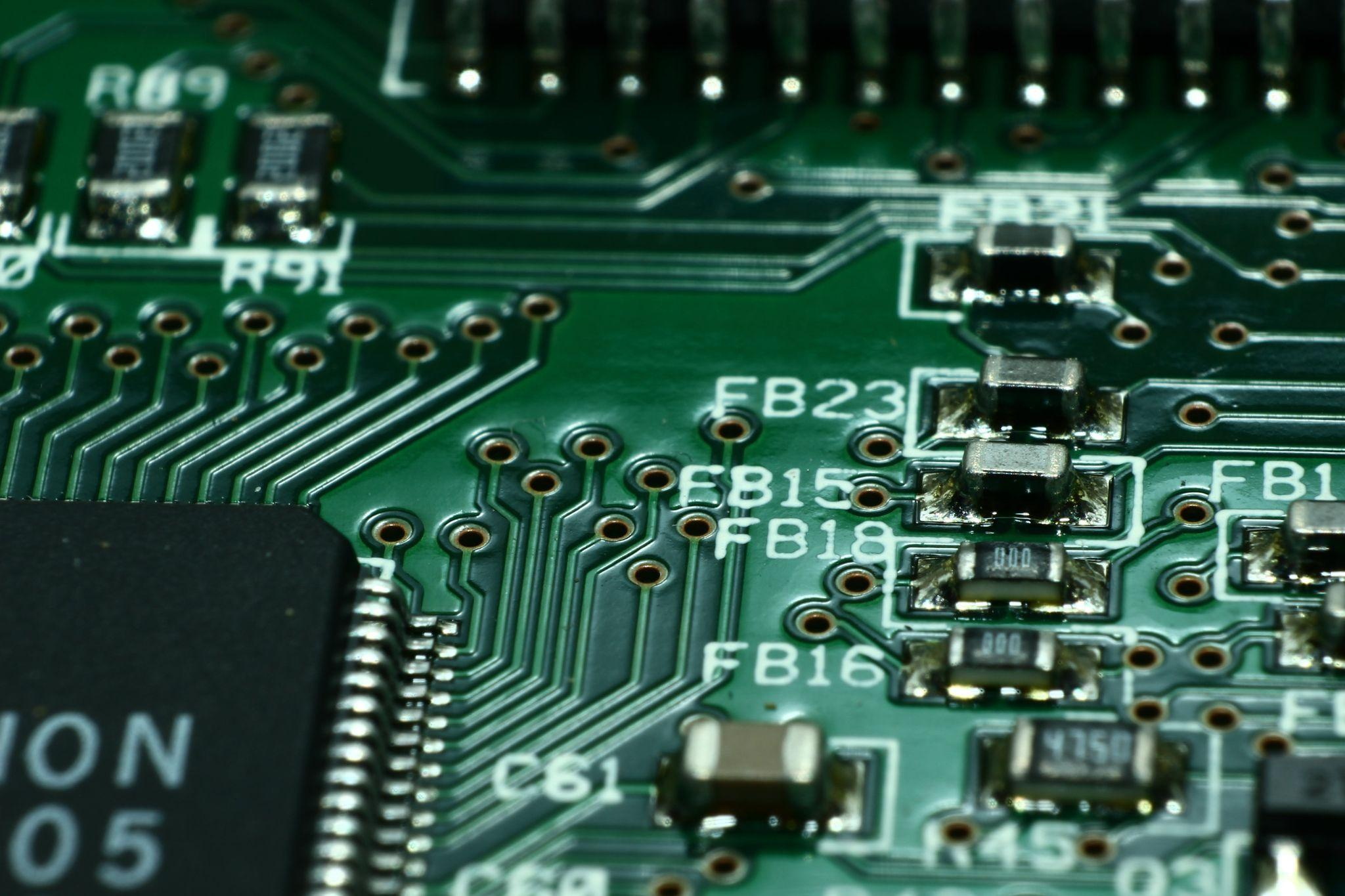

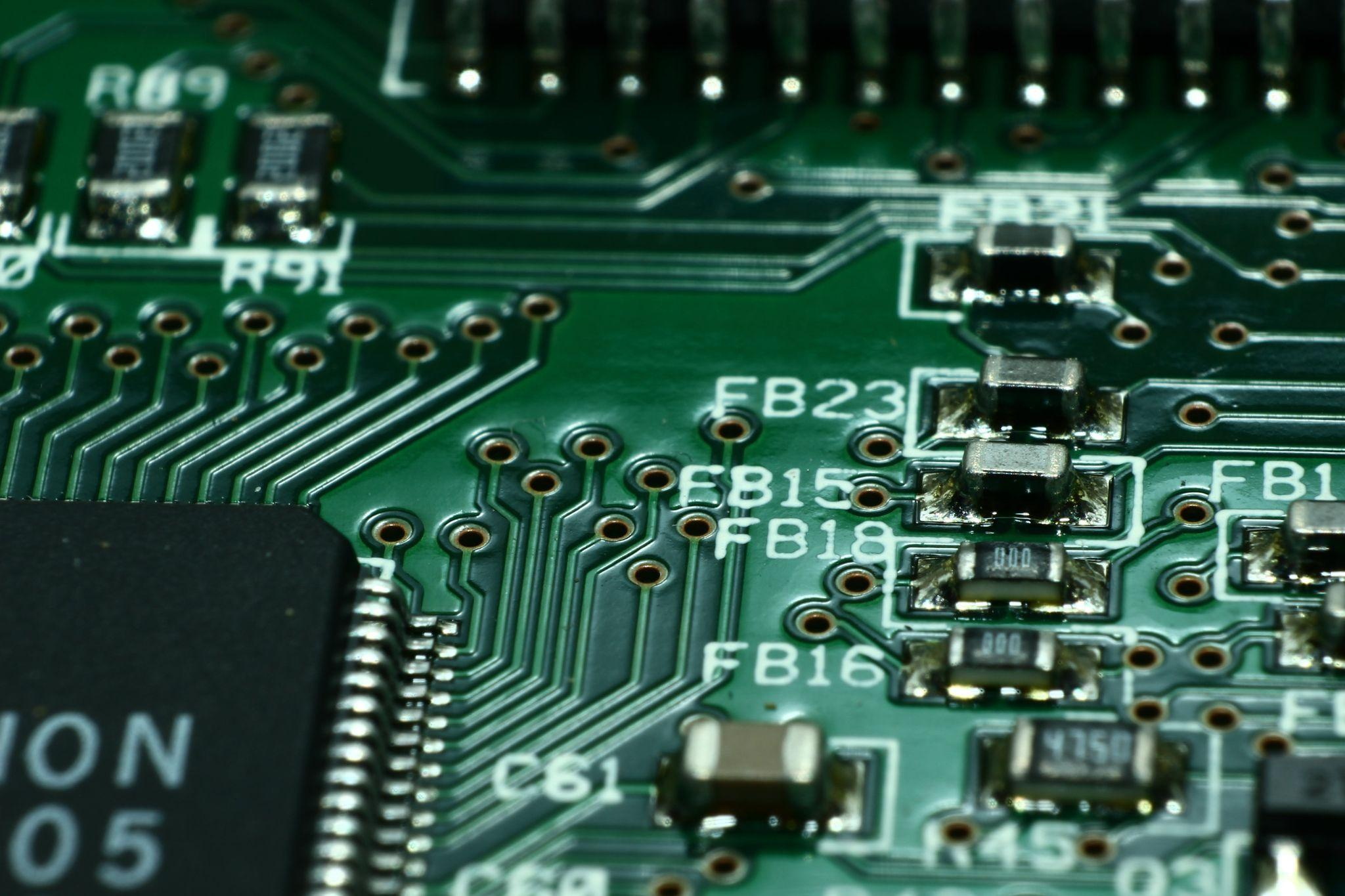

PCB assembly usually costs between $0.02 and $0.05/square inch. However, this estimate is based on several factors, including labor and overhead expenses. Most PCB assembly costs typically involve purchasing electronic components like resistors, capacitors, microchips, and connectors.

Besides this, the cost of your finished product will also be influenced by the caliber of your components, depending on how expensive or affordable parts you opt for. Additionally, you can cut the price short if you choose low-skilled labor and few overhead expenses.

However, if you're choosing a complex design with more layers and smaller components, you should be ready to pay more for that!

Factors Determining The PCB Assembly Cost

The cost of PCB (Printed Circuit Board) assembly can vary significantly depending on various factors. Understanding these factors is essential to manage costs effectively and make informed decisions. Here are a few top reasons you should know:

1. Selection of Material

The cost of the board is directly proportional to the type of material you select. It plays a pivotal role in impacting not only the price but also the overall performance, reliability, and longevity of electronic devices.

The following variables may influence the choice of material:

PCB Substrate Material: The choice of substrate material for the PCB has a substantial impact. Materials like FR-4 are common and cost-effective, ranging from $1.00-$8.00 per square foot, while specialized substrates like ceramic or flexible materials can be more expensive. The ceramic ones cost you $5 to $50 per square foot, while flexible materials like polyimide or PTFE for flex PCBs may range from $2 to $20 per square inch. The choice depends on the application's requirements for electrical performance, thermal management, and flexibility.

Temperature Reliability: Ask yourself questions like: In a controlled environment, can the material tolerate a typical range of temperatures without heating? Mainly, the materials used in PCBs are designed to pass high-temperature operating tests.

Copper Thickness: The thickness of the copper layers in the PCB affects its current-carrying capacity and heat dissipation. For instance, thin copper (1 oz to 2 oz) can cost you $5-$20 per square foot. In contrast, thick copper 4 oz and above can cost you $20 to $50. Thicker copper layers are more conductive but cost more due to the additional material and processing required.

Solder Paste: The quality of solder paste used during assembly is critical for reliable solder joints. High-quality solder paste ranging from $40 to $80 per syringe or jar ensures good wetting and reduces the risk of defects. On the other hand, when you choose standard or lead-free solder paste ($20-$50), you can get a minimal performance with no extra additional functions.

2. PCB Dimensions

A PCB's size is one of the most critical variables that influence cost. Usually, the amount of circuits you're using will determine the size of your final project.

A printed circuit board (PCB) for a digital watch will have fewer components and will be cheaper to manufacture than a PCB for a desktop computer or laptop. Similarly, a large industrial machinery's PCB will be bigger than the boards used in most home devices.

These are some of the most popular dimensions in PCB manufacturing:

Small PCBs: They are categorized into 2x2 to 4x4 inches, being the most cost-effective. If you go for them, you'll be spending around $5 to $20 per board, depending on complexity.

Medium-Sized PCBs: They are of moderate pricing from $10 to $30, depending on your specification type. You can easily get them in 4x4 to 6x6 inches.

Large PCBs: They are 6x6 inches and above, resulting in expensive boards. Their prices vary widely, ranging from $20 to several hundred dollars per board.

Additionally, the price of a board will also be influenced by how much space each component takes up. Specific boards are made with fewer components, given production costs and efficiency.

Ultimately, one of the primary determinants of the total cost will be the size of your PCB design. A small PCB manufactured in huge volume may come out cheaper overall than a large PCB manufactured in low volume.

3. The PCB's Thickness and Aspect Ratio

Until recently, a PCB's thickness had little bearing on the total cost, but this is likely to alter in the years to come. Purchasing, laminating, and shaping thicker material into a printed circuit board can be more expensive, mainly if the design is complex.

Since less material is needed for the current manufacture, thinner material of 0.8 mm or less often places a line of PCBs at a slightly lower price, ranging from $10 to $30 per board. Moreover, the material used in a particular manufacture can affect a board's thickness-related costs.

However, if you go with thick PCBs 2.0 mm or more, your price could go from $15 to $40 or more. The price difference could also be substantial if a thicker board has a more significant aspect ratio.

A board with large dimensions and numerous layers will need more material and labor during manufacture. Therefore, measuring parameters or the number of layers contributing to the thickness may have a more significant effect on the final cost than the thickness of the board itself.

4. Performance and Quantity

Another thing that significantly affects the cost is the performance and quantity you need. While some design flaws are simple to identify, others may be more challenging. Quality control will improve with the number of functionality tests you run on your PCB design. Higher tolerance levels will result from it, which will ultimately cut down on rework and manufacturing delays.

Moreover, every quantity order (except bulk orders) has a set price per square inch. As a result, the price per unit will decrease the more units you order. Once you know how much things will cost, you can make a project budget and determine how much profit you need to include in your PCB assembly price. It will then be simple to choose the costs for each item your business produces.

Why Does PCB Assembly Cost Matter

If you're working on a project with tight budgets or deadlines, opting for the cheapest PCB assembly is often a temptation. However, it's crucial to understand that companies may have varying PCB assembly costs. Here are a few reasons that indicate the necessity of knowing the assembly cost.

1. Component Placement Accuracy

Accurate placement of components on the PCB is crucial for the functionality and performance of electronic devices. When you opt for higher assembly costs, you're at peace since you know you're getting better equipment with processes that ensure precise component placement. It also reduces the likelihood of soldering errors and misalignments.

2. Soldering Quality

The soldering process is critical for creating reliable electrical connections. Higher assembly costs can mean better soldering equipment and skilled technicians, resulting in consistently high-quality solder joints. Poor soldering may lead to electrical failures, signal integrity issues, and long-term reliability problems when selecting.

3. Component Inspection and Testing

Costlier PCB assembly often includes rigorous inspection and testing processes. This can involve automated optical inspection (AOI) and in-circuit testing (ICT) to identify defects early in production, ensuring that only fully functional PCBs make it to the final product.

4. Advanced Manufacturing Techniques

High-priced PCB assembly can involve advanced techniques like surface mount technology (SMT), which enables smaller, more densely populated boards, reducing the PCB's physical footprint. This can be crucial for miniaturized electronic devices.

5. Compliance and Certification

Some industries demand compliance with specific standards and certifications, such as IPC standards for PCB assembly. Higher assembly costs often include the investment required to meet these standards, ensuring that the PCBs meet industry-specific requirements.

Why is PCB Assembly Service So Expensive?

PCB (Printed Circuit Board) assembly services can be expensive due to several technical and logistical factors. One significant aspect is the precision and complexity of the assembly process. High-precision equipment, like pick-and-place machines and reflow ovens, is required for accurate component placement and soldering. This precision is crucial in modern electronics, where components are often densely packed and miniaturized.

The cost of such equipment can be substantial, contributing to the overall expense. Additionally, the quality of materials used, such as the PCB substrate and solder paste, directly affects the reliability and performance of the final product. High-quality materials can come at a premium, impacting costs.

Besides, rigorous testing and inspection processes, essential for ensuring defect-free PCBs, add to the overall expense. According to industry sources, PCB assembly services can range from $0.10 to $0.50 per component, depending on complexity and volume. The intricate nature of modern electronics and the demand for high reliability contribute to the relatively high cost of PCB assembly services.

Moreover, selecting a double-sided assembly may result in an increased cost for your PCB assembly quote. This is because the process of putting the parts on both sides of the circuit board has to be done twice. Additionally, it requires additional solder stencil creation, SMT machine programming, and other tasks, which raises the cost of PCB assembly.

How to Estimate/Calculate the PCB Assembly Cost

Estimating PCB assembly costs involves considering various technical and logistical factors. Here are a few factors to consider when calculating.

Component Cost: Begin by determining the cost of individual components. For example, resistors ($0.1-$1), integrated circuits ($1-$10 per chip), connectors and switches ($0.10-$5 each). You can obtain this information from suppliers or distributors. Sum up the prices of all components required for the PCB assembly.

Labor Costs: Calculate labor costs based on the time required for assembly. This depends on the complexity of the design and the assembly method used. When you opt for SMT assembly, the labor cost would be $15-$30 per hour. Similarly, if you go for specialized or prototype assembly, labor costs will range from $20-$50 per hour. Moreover, skilled technicians may charge higher hourly rates.

Overhead Costs: Consider overhead costs, including rent for the assembly facility, utilities, maintenance, and equipment depreciation. These costs are typically spread across the total production volume and will charge you about 20% to 40% of the total cost.

Materials: Account for the cost of materials such as the PCB substrate, solder paste, and any specialized materials required for the assembly.

Testing and Inspection: Include the cost of testing and inspection equipment, labor, and necessary rework or repairs. The basic functional testing is $0.10-$2 per board.

Quality Assurance: Factor in the cost of adhering to industry standards or certifications, which may involve additional testing and documentation.

Volume: The number of PCBs being assembled affects costs. Economies of scale often apply, with larger production runs resulting in lower costs per unit.

To put it simply, the overall PCB assembly cost (C) can be calculated using the following formula:

C-Total Cost = Component Cost + Labor Cost + Overhead Cost + Materials Cost + Testing and Inspection Cost + Quality Assurance Cost

To estimate the cost per unit, divide the total cost (C) by the number of assembled PCBs.

Here's a hypothetical cost comparison chart for PCB assembly services based on different production volumes:

|

Production Volume

|

Cost Per Unit (in USD)

|

|

1-10 units

|

$50-$200

|

|

10-100 units

|

$20-$100

|

|

100-1000 units

|

$10-$50

|

|

1000-10000 units

|

$5-$30

|

|

10000+ units

|

$2-$20

|

Things to Consider When Estimating PCB Assembly Cost

An assembly company's price is among the most important considerations. Suppose you wish to lower the price of PCB assembly for yourself. In that case, you should take the following into account:

1. The Standing of PCB Manufacturers

The first thing you must look at when estimating the cost is the reliability and effectiveness of the firm's machinery. Doing so will help you in the long run since when you face issues, they will often handle them carefully and provide replacement PCBs without delay.

Some vendors will gladly give you a new batch of PCBs free of charge if anything needs to be corrected in the first place. Selecting a reputable worldwide PCBA manufacturing firm like PCBasic guarantees you will receive professional services that meet your needs. You should also consider the company's service, degree of general knowledge, availability, and the time it takes them to arrive at your location.

2. PCB Assembling Techniques

There are several ways to put PCBs together. Printing circuits use conductive ink to create a PCB on copper. Next, they put the board on a device with several heads and squirt conductive ink or hot solder paste onto it.

To improve solder adhesion to the PCB, they flux the component or pad before soldering. After that, they solder each pad thoroughly after placing the components on it. Although this procedure can be completed by hand, it is typically carried out by a robotic machine with numerous heads that can replace parts and reflow a solder joint in case of a problem.

The most popular techniques for assembling PCBs are Automatic Insertion Machines (AIM), Leadless PCB construction, Solder bumping machines, and In-house assembly.

3. Board Dimensions and Layer Count

A printed circuit board's thickness and current carrying capacity are directly correlated with the number of layers on the board. A top-layer copper-clad enables a board with materials as thick as 0.020" to be produced.

The layer count of a PCB has a profound impact on its functionality and complexity. Multi-layer PCBs, with their numerous signal and ground planes, offer more routing options, facilitating intricate and dense circuit designs. However, this complexity comes with increased manufacturing and material costs.

Furthermore, board size is crucial in determining whether the PCB can fit within the device's enclosure. An oversized PCB may require a custom or larger enclosure, increasing material and manufacturing costs.

Board size impacts material and labor costs, enclosure fit, and heat management, while layer count influences functionality, signal integrity, power distribution, and design flexibility. Therefore, the selection should align with the specific technical requirements of the application, ensuring that the PCB meets its intended purpose while effectively managing costs.

4. Board and Component Substance

The materials used in constructing the PCB (Printed Circuit Board) and its components are of utmost importance in PCB assembly. Common materials like FR-4 are cost-effective and widely used, making them suitable for various applications.

However, materials like ceramic, flexible PCB substrates, or high-frequency laminates might be required for specialized needs. These materials are often more expensive but offer specific electrical or mechanical properties necessary for the project.

Furthermore, the choice between leaded and lead-free components affects costs. Due to environmental regulations, lead-free components are preferred in many applications, but they tend to be slightly more expensive. However, this cost difference is usually justified by the long-term benefits of compliance and reduced environmental impact.

The materials that go into making your board can affect both its conductive properties and capacity to release heat when soldering is done. Your board's electrical conductivity may vary depending on the thickness of the copper used in it.

For all general uses, standard FR4 or materials comparable to it are appropriate. Better conductor pathways between components and faster signal rates are prerequisites for today's high-speed digital systems.

5. Technology Used (Through-Hole vs. SMT)

The choice of technology used in PCB (Printed Circuit Board) assembly is a pivotal decision that significantly impacts the manufacturing process, cost, and the final performance of the electronic device. There are primarily two major PCB assembly technologies: Surface Mount Technology (SMT) and Through-Hole Technology (THT), each with its own considerations.

Generally, through-hole boards are less expensive and more straightforward to put together than surface mount boards, although they are more prominent. Integrating smaller components using surface mount technology is also more difficult unless they are positioned at the top or bottom of the board.

Contrarily, through-hole components are hand-placeable anywhere on a board. Skill is needed to create through-hole boards, and proper design is necessary to guarantee that all leads line up with each component.

Due to their smaller size, SMT components are easier to install but come at a higher cost. Since one must understand soldering methods before manufacturing boards that work correctly, they are also more difficult for beginners. SMT parts don't need as much human assembly and can be put on a board anywhere by a machine.

6. Design Complexity

Design complexity in PCB assembly refers to the intricacy and technical sophistication of the layout and arrangement of components and circuits on the printed circuit board. As electronic devices become increasingly advanced, the complexity of PCB designs also grows.

One fundamental aspect of design complexity is component density, which reflects how tightly components are packed on the board. A higher component density often requires more precise placement during assembly, increasing labor costs.

Moreover, it can make visual inspection and quality control more challenging, potentially raising the risk of defects. Signal routing is another significant concern in complex designs, particularly in applications with sensitive signals. Careful planning and routing are essential to avoid interference and crosstalk. Advanced design tools are often required to effectively manage signal paths, adding to design and manufacturing costs.

How to Reduce PCB Assembly Cost

Now that you know the approximate cost of a PCB assembly, follow these recommendations to cut costs: This advice is based on the premise that you are still in the early stages of planning and have yet to finalize your PCB assembly design.

1. Locate an Affordable PCB Assembly Firm

Today, there is a wide variety of PCB assembly service providers, which all have distinct price ranges. When ordering PCB assembly online, it's essential to shop and compare prices from several firms to locate one that provides quality service at a reasonable price.

Recognize your preferences for the manufacturer or company. Try to choose a PCB assembly firm that delivers value-added services, has a low minimum order quantity, and provides discounts for large projects.

Remember that the least expensive PCB assembly service might be insignificant if the parts and craftsmanship are subpar. To learn more about the reputation of any business you're considering working with, read reviews about them as well.

2. Improve the Design of the PCB Assembly

A printed circuit board assembly's design can significantly affect the assembly's total cost. Simplifying the design while maintaining all necessary functionalities is crucial for cost-effectiveness.

If feasible, plan for surface-mount components instead of through-hole PCB assemblies and use fewer layers. Assembling components by hand takes less time when fewer holes are on the board, which can result in cost savings.

Reduced holes will also require less material, which could result in a cheaper price. That's because the cost of PCB assembly for each component is what matters. It's crucial to employ standard component sizes that are inexpensive and easily sourced to lower the price of PCB assembly further.

3. Employ PCB Assembly Automation

Purchasing automated PCB assembly equipment may seem like a big upfront expense since it is more costly than hand assembly.

Nevertheless, by cutting down on assembly expenses and time, they will end up saving you money.

If you can afford it, automating the PCB assembly process is a great way to reduce expenses. This is due to the machine's faster ability to insert and solder components than a human operator.

In addition to lowering the price of PCB assembly, automated assembly will help to increase product quality by minimizing the impact of human error. Therefore, even though it's usually more expensive initially, the labor savings make it an investment that pays off over time.

4. Raising the Order Quantity

A method of lowering the total cost of PCB assembly is to place larger orders. This is so that you can avoid paying the setup fee that most assembly businesses charge for each new purchase by ordering numerous boards simultaneously.

If you place larger orders, you may be able to bargain for a lower price per board because many PCB assembly businesses provide discounts for larger orders. However, not everyone can do this because they may not have the resources to handle a bigger order. Therefore, you must discuss this with your vendor beforehand.

Conclusion

Understanding the intricacies of PCB assembly costs is essential for anyone in the electronics industry. The cost, typically ranging from $0.02 to $0.05 per square inch, is influenced by materials, board size, and design complexity. While cost-cutting measures may be tempting, higher assembly costs often lead to better accuracy in component placement, improved soldering quality, and comprehensive testing, all of which directly impact the reliability of your electronic devices.

When estimating PCB assembly costs, consider the standing of manufacturers, assembly techniques, board dimensions, board and component materials, technology used, and design complexity. Balancing cost-efficiency with quality components and manufacturing processes is crucial for successful electronic projects, ensuring your devices perform reliably and meet your budgetary constraints.