How does PCBasic realize the fast production of multi-species and Small batch PCBAs?

Now let's talk about the specific implementation process of our

PCBasic to achieve rapid production of multi-species small batch PCBAs.

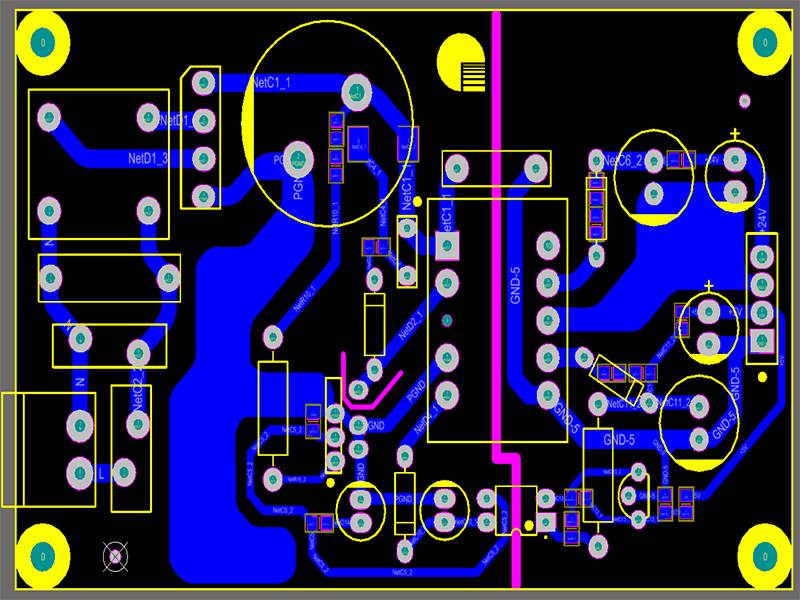

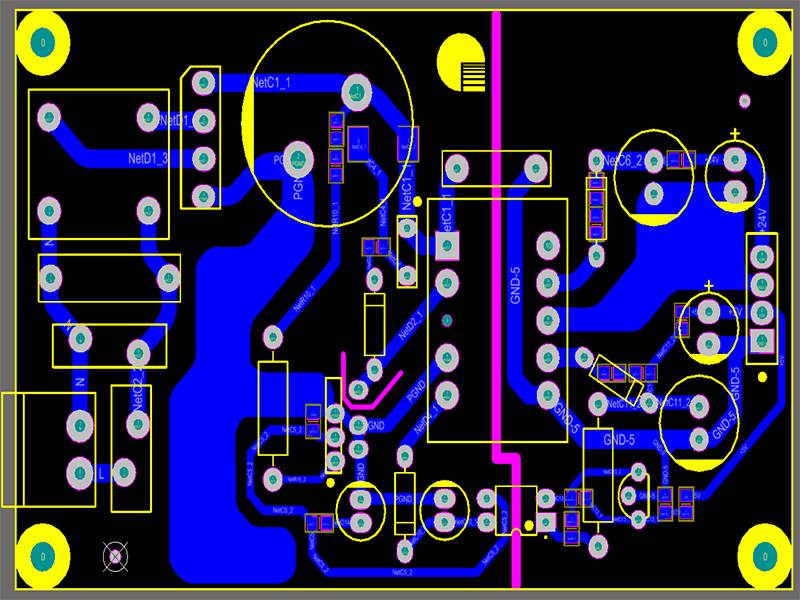

1.Design a flexible PCB layout

At PCBasic, we have experienced electronic engineers in the industry in

PCB layout design.

to support the installation and connection of many devices as flexibly as possible

to reduce the need to change the layout.

Universal connectors or programmable chips can be used to support different electronic components.

2.Optimize procurement and inventory management

We at PCBasic have established long-term strategic partnerships with component suppliers

in the industry to achieve a win-win situation for both parties.

With an efficient supply chain management system that optimizes the procurement process,

we are able to handle the supply of raw materials and components on time.

Through proper inventory management and logistics planning,we can respond to customers' order

requirements faster while reducing inventory and waste.

3.Adopting efficient SMT placement equipment

PCBasic has established a high standard of 8 automated production lines

and purchased the industry's most efficient surface mount technology (SMT) equipment

to improve production efficiency and reduce manual operations.

We use automated tools such as automatic placement machines and automatic plug-in machines

and wave soldering equipment to reduce manual operations and production cycles.

4.Implementation of standardized process flow

We at PCBasic have established a standardized production process flow (SOP), a unified production standard

and process that helps improve production efficiencyand product quality and reduce costs and error rates.

For this reason, the standardized process flow can well support multi-species production.

5.Application of intelligent manufacturing technology

PCBasic has been increasing its R&D strength in intelligent manufacturing technology,

and has achieved real-time monitoring of production line data in industrial Internet,

Internet of Things, and smart logistics management system,

and the production efficiency and product quality have enjoyed a high reputation in the PCBA manufacturing industry.

At the same time, PCBasic can improve and optimize the production process through data analysis and mining,

which forms a positive cycle and better supports multi-species small-batch production.

Our intelligent manufacturing system empowers more digitalization of the industry.

6.Equipped with high-quality human resources

Multi-species small batch PCBA, PCBasic has been equipped with higher-quality human resources.

PCBasic has technical personnel, quality control personnel,

and supply chain management personnel.

We have long-term industrial alliances

with top academic research institutions in China and Chinese universities.

Reasonable allocation of human resources helps

to improve production efficiency and product quality and shorten the production cycle.

7.Introduction of Programmable Logic Controller (PLC)

PCBASIC uses programmable logic controller (PLC) for automated control

in the production of multi-species and small-lot PCBAs. PLC can automatically control production equipment

and processes according to preset logic and programs to improve production efficiency and production quality.

8.Implementation of Quality Management System

We have a well-developed quality management system,including quality control and quality assurance,

which can help ensure that the quality and performance of our products meet the requirements.

The quality management system should cover everything

from raw material procurement, production process,

and finished product inspection to fully guarantee the quality

and reliability of the products (detailed

quality inspection process).

9.Put in place flexible production planning

To meet the demand for quick production of multi-species and small-lot PCBA,

PCBasic's production plan is all automated production,

and the MES system with independent intellectual property rights gives more flexibility

and adjustability to small-lot production.

PCBasic adopts the advanced planning system

APS to realize intelligent production planning and scheduling,

and adjust the production plan in real time according to market demand and order changes

The system can improve production efficiency and production capacity.

10.Adopt a rapid response mechanism

In the production of multi-species small batch PCBAs,PCBasic has established a rapid response mechanism

on time to deal with customer feedback and market demand changes on time.

The rapid response mechanism includes rapid production adjustments,

rapid product updates, improvements, etc. We promise to deliver small lots in 24 hours at the earliest.

Only by constantly following up on the market,updating and improving,

can we maintain our competitiveness and market share.

To sum up, realizing the fast production of multi-species and small batch PCBAs requires comprehensive consideration

and coordination in many aspects such as PCB layout design, procurement, and inventory management,

SMT placement equipment, process flow,intelligent manufacturing technology, human resources,

PLC control, quality management system, production planning and quick response mechanism.

Only on the basis of comprehensive consideration of various factors can efficient, fast,

and reliable production be achieved.

PCBasic has done it, for more product information,please pay attention to the

product details page.