Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Electronics Manufacturing: A Guide to EMS and Contract Services

The electronics industry has been integrated into every part of our lives. From mobile phones to medical devices, people's demand for high-performance electronic products is getting higher and higher. To meet this demand, many enterprises have begun to rely on professional electronic manufacturing services to quickly turn product ideas into reality.

In simple terms, electronic manufacturing is the process of designing, assembling, testing and delivering electronic products. Electronic manufacturers are responsible for a wide variety of products, such as circuit boards, consumer electronics, automotive electronics and industrial equipment.

This article will take you through the basic concepts of electronics manufacturing, including EMS industry and electronics contract manufacturing, and explain how they can help enterprises reduce costs, improve efficiency, and accelerate the time to market for products.

Electronics manufacturing is the entire process of making electronic products, including design, manufacturing, assembly and testing. Professional electronic manufacturers are usually responsible for every step from circuit board production to component assembly and product inspection to determine if they are qualified. These processes can ensure the stability and reliability of the products and they are widely used in automobiles, medical care, communications and daily electronic products.

Electronics Manufacturing Service (EMS) refers to a complete set of solutions from product development to mass production provided by a third-party professional EMS company for brands or original equipment manufacturers (OEMs). In simple terms, it means that enterprises outsource the production of their products to experienced manufacturers.

These services usually include:

• Component Procurement and Supply Chain Management: EMS company will source electronic components for you based on the bill of materials while ensuring quality and controlling costs. At the same time, it is also responsible for material inventory and logistics coordination.

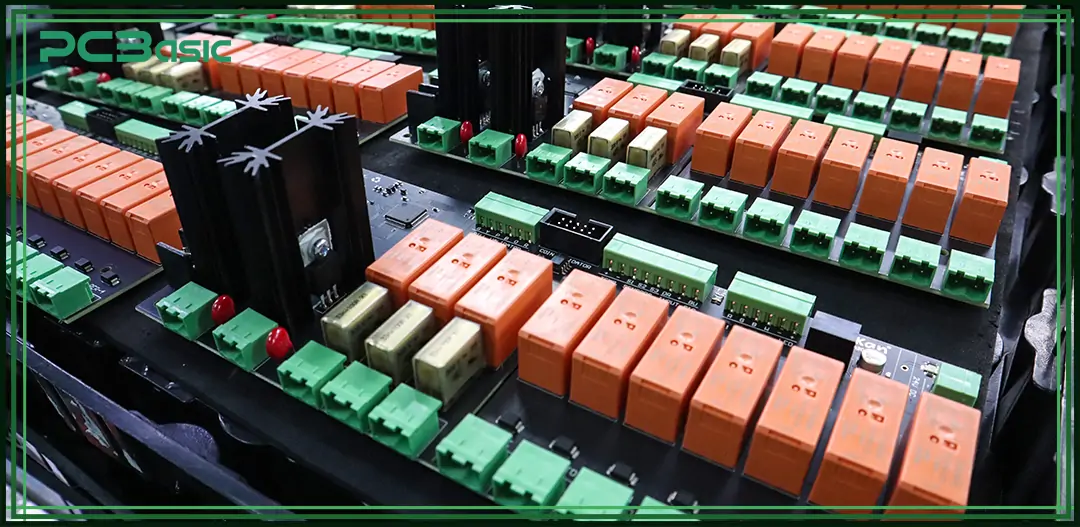

• Component Assembly: For instance, components are soldered onto circuit boards, including various processes such as PCB assembly, SMT surface mounting, and through-hole mounting.

• Testing and Quality Control: During the production process, multiple rounds of inspections will be carried out, such as functional tests, AOI (automatic optical inspection), X-ray and so on, to ensure that the products have no poor soldering or component defects.

• Box Build Assembly: In addition to circuit board assembly, it can also complete the assembly and packaging of the entire product and directly provide the finished products.

Through these services, EMS suppliers can help enterprises significantly reduce production costs, shorten delivery cycles, and avoid the equipment investment and human resource management required for building their own factories. OEM manufacturers can focus more on product research and development, marketing, and brand building, and concentrate their energy on core businesses.

Electronics Contract Manufacturing (ECM) is a common outsourcing method, which refers to the OEM (Original Equipment Manufacturer) entrusting the production tasks of products to professional EMS suppliers, who complete the manufacturing process based on design drawings and technical requirements.

The advantage of this model lies in that OEM enterprises do not need to build their own factories or purchase equipment, which can significantly reduce the initial investment and operational risks. Meanwhile, EMS contract manufacturing usually has mature production systems and professional teams, which can ensure product quality while accelerating production progress and shortening delivery time, enabling products to be launched on the market more quickly.

In addition, EMS contract manufacturing can quickly adjust production capacity according to market demand, helping brands respond flexibly to orders at different stages. It is a core part of the EMS industry and an important choice for many technology companies to enhance their competitiveness.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

The entire electronics manufacturing service process typically includes the following key steps, each of which directly affects product quality and delivery efficiency:

1. Design Review and BOM Analysis:

Before production begins, engineers evaluate the product design and Bill of Materials (BOM) to ensure the structure is reasonable and manufacturable. This helps identify potential issues early, avoiding rework and waste.

2. Component Procurement:

Based on BOM, EMS suppliers source electronic components through reliable channels, ensuring all materials meet quality standards and avoiding counterfeit or substandard parts.

3. PCB Manufacturing:

This step involves producing the printed circuit board (PCB), which serves as the foundational structure of the entire electronic product. It must be manufactured strictly according to design files and process requirements.

4. Electronics Assembly:

The sourced components are mounted onto the PCB using methods such as SMT (Surface Mount Technology), through-hole insertion, or a combination of both, ensuring precise and reliable electrical connections.

5. Testing and Inspection:

After assembly, various tests are conducted, including AOI (Automated Optical Inspection), X-ray inspection, and functional testing. These tests help detect soldering defects, component issues, or performance anomalies, ensuring each board meets the required standards.

6. Box Build Assembly:

Beyond PCB assembly, EMS companies can also provide box build services, integrating all electronic and mechanical parts into a complete final product and performing final packaging.

These steps are tightly connected and equally important. For professional electronics manufacturers, strictly following each process is essential to deliver high-quality and consistent electronic products.

Electronics manufacturing services support various industries, including:

• Consumer Electronics – Smartphones, wearables, and home appliances

• Automotive – Advanced driver-assistance systems (ADAS), infotainment

• Medical Devices – Diagnostic equipment, patient monitoring systems

• Industrial & IoT – Automation, sensors, and smart devices

When looking for a reliable electronics manufacturer, PCBasic is a leader in the field of high-quality EMS manufacturing in China. With over 15 years of experience, PCBasic offers one-stop electronics manufacturing services from prototyping to mass production. As a leading EMS company, we assure you that every project is precise, traceable and fast.

Whether you need a fast-delivery PCB assembly or a full-system integration solution, we can offer cost-effective, scalable and reliable electronics manufacturing services to meet your project requirements.

• Extensive Industry Experience

Over 10 years of experience in PCB design and project management, serving various sectors, including consumer electronics, industrial control, medical devices, and IoT.

• One-Stop Manufacturing Services

From prototyping, PCB fabrication, and component sourcing to SMT assembly, full product assembly, testing, and shipping—PCBasic offers complete end-to-end solutions, reducing communication and management costs for clients.

• Multi-Factory Operational Layout

Shenzhen factory specializes in small-batch, quick-turn orders, while the Huizhou factory is equipped for large-scale automated production—flexible to handle a wide range of project demands.

• Strong In-House Processing Capabilities

Self-operated stencil and fixture production facilities, along with a CNC precision machining center, support customized tooling and high-accuracy mechanical part processing, improving both assembly precision and delivery speed.

• Smart Supply Chain System

Equipped with an intelligent central warehouse for electronic components, PCBasic ensures original and genuine part supply. Combined with a one-click BOM import and instant online quoting system, this greatly enhances procurement speed and order efficiency.

• Strict Quality Control System

Certified with ISO 9001, ISO 13485, IATF 16949, ISO 14001, and UL, PCBasic ensures top-tier quality standards across consumer, medical, and automotive-grade electronics.

• Strong R&D and Innovation

Ongoing collaboration with PhD teams from top universities, with over 20 patents in quality control and production systems, demonstrating continuous progress in manufacturing innovation.

As the electronics industry continues to grow, businesses are placing greater demands on efficient and reliable electronics manufacturing. Partnering with a professional and trustworthy EMS supplier allows OEM manufacturers to focus on product development and innovation, while leaving the complex production process to an experienced team.

Whether you're a startup or an established brand, choosing the right electronics manufacturer to provide EMS contract manufacturing services is key to ensuring product quality, controlling costs, and achieving long-term success.

Ready to start your project? Choose PCBasic – your reliable partner in electronics assembly services, and a leading name in the global EMS industry.

Assembly Enquiry

Instant Quote