Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > What are PTFE and PTFE Dielectric Constant? A Complete Guide

PTFE or Polytetrafluoroethylene is called one of the most versatile synthetic products used in modern industry. PTFE was discovered by researchers in 1938, and since then, it has been included in different industries in different applications, which is due to its extraordinary properties. The PTFE dielectric constant forms a basic function that makes it even more valuable for electrical and electronic applications. We defined PTFE for its tetrafluoroethylene high chemical resistance, thermal stability, and electrical insulation. Polymer consists of Tetrafluoroethylene molecules with a carbon backbone surrounded by fluorine atoms. The structure is resistant to chemicals and has very good thermal stability.

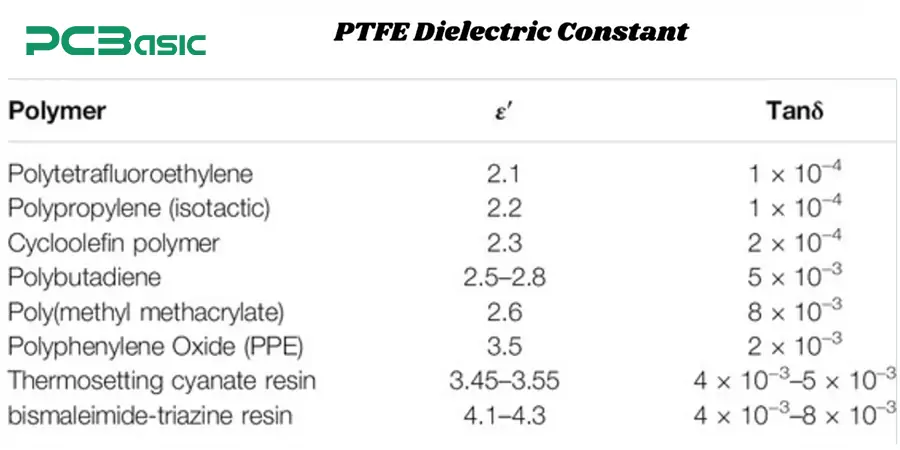

PTFE dielectric constant ranges from 2.0 to 2.1 at ambient temperature, which is a result of its unique PTFE structure of molecules. PTFE's dielectric constant indicates how it can hold electric energy in comparison to a vacuum. It is a measurement of how well the material insulates against electrical current while maintaining signal integrity. These are properties that qualify PTFE for application in high-frequency usage where signal maintenance is of primary concern.

Dielectric properties of the material remain unchanged when subjected to a broad range of frequencies, from direct current to microwave frequencies. This property makes it extremely useful in telecommunications, radar systems, and aerospace technology. The low loss tangent of PTFE is the reason for low signal loss, and hence, it is employed by engineers in high-performance circuit boards and coaxial cables.

In this blog, we'll take a closer examination of the molecular structure of the characteristics of PTFE and differentiate PTFE from its branded equivalent Teflon. You'll discover how its dielectric constant responds to various frequencies and how it is used in practical applications in various industries. Engineers looking for technical information or anyone interested in this incredible material will benefit from this close examination of PTFE and its dielectric characteristics.

PTFE, which stands for polytetrafluoroethylene, is an interesting original story. Dr. Roy Plunkett found it by chance in 1938 while working in DuPont. In this synthetic fluoropolymer, carbon and fluorine atoms were typically arranged, giving exceptional properties.

You will find polytetrafluoroethylene in three most important physical shapes: granular resin, fine powder, and water-based dispersion. Manufacturers produce granular PTFE through suspension polymerization, which works well for casting and RAM-extrusion processes. Fine PTFE powder comes from controlled emulsion polymerization and helps with paste extrusion applications. It increases the resistance when other materials are added. The PTFE dispersion requires several spreading agents under aquatic polymerization and the best feature of coating applications.

Regular (incomplete) PTFE is not the only available option. The revised versions provide better properties. PTFE filled with glass makes the content very strong during compression. PTFE filled with bronze is still more stable. Carbon-filled PTFE works better, while stainless steel-filled PTFE is exceptionally well.

You will find polytetrafluoroethylene in three most important physical shapes: granular resin, fine powder, and water-based dispersion. Manufacturers produce granular PTFE through suspension polymerization, which works well for casting and RAM-extrusion processes. Fine PTFE powder comes from controlled emulsion polymerization and helps with paste extrusion applications. It increases the resistance when other materials are added. The PTFE lookup requires several spreading agents under aquatic polymerization, and the best feature of coating applications.

PTFE molecules naturally orient themselves in relation to one another. This forms crystalline areas, wherefore PTFE tends to have 92-98% crystallinity.

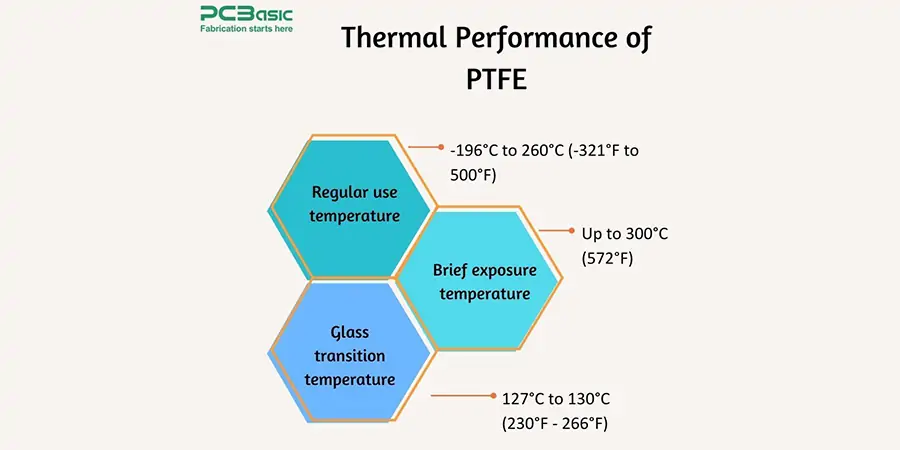

The material has excellent thermal resistance with a melting point of around 327°C (620.6°F). PTFE works well over a very broad temperature range:

The material behaves differently from typical thermoplastics when it melts. Instead of flowing freely, it turns into something like a very thick gel.

Teflon is a commercial brand name for polytetrafluoroethylene (PTFE), which was the DuPont brand in 1945. Dr. Roy Plunkett happened to find PTFE while working in DuPont's Jackson Laboratory in New Jersey. The company saw the commercial ability of this unique material and made it one of the world's most recognized chemical brands.

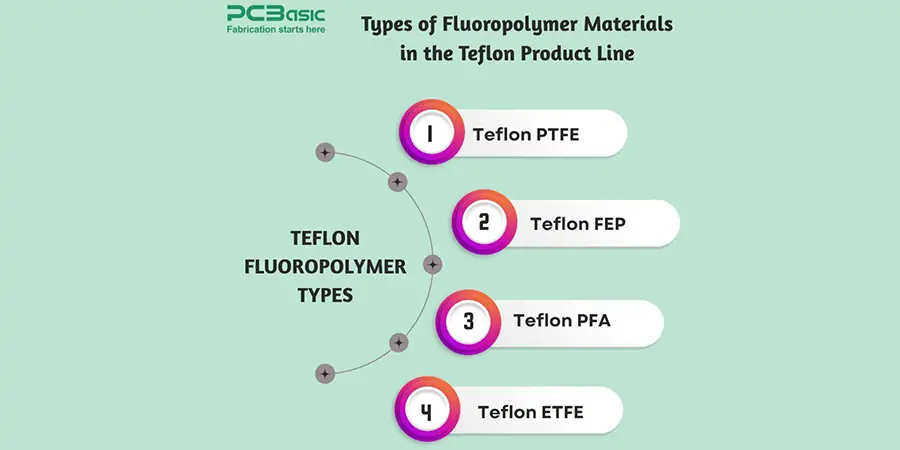

DuPont began to market this revolutionary material under Teflon brand of industrial use. The name became so common that people started using "Teflon" to describe any non-stick coating. However, only DuPont's PTFE products can legally use this name. The Teflon brand grew to include several fluoropolymer products beyond the original PTFE formula.

The Teflon product line includes these fluoropolymer materials:

Each type has unique properties that work best for specific uses, from cookware coatings to industrial equipment.

The main difference between PTFE and Teflon is quite simple- all Teflon is PTFE, but not all PTFE is Teflon. PTFE is the real chemical compound polytetrafluoroethylene, while Teflon is the branded version of PTFE originally developed by DuPont. This ratio is like acetylsalicylic acid and aspirin- a chemical compound, and the other is a brand name.

In 2015, DuPont closed its performance chemical division at a new company called Chemours, which became the owner of the Teflon brand. The name of Teflon is still non-stick for most people, but it technically refers to only PTFE products and is sold under the official Teflon brand.

|

Feature |

PTFE (Polytetrafluoroethylene) |

Teflon™ |

|

Nature |

Chemical compound |

-- |

|

Chemical Name |

Same compound—PTFE |

Same compound—PTFE |

|

Brand Owner |

Generic (used by many manufacturers) |

Originally DuPont, now owned by Chemours (since 2015) |

|

Usage |

Used in many industrial, mechanical, and consumer applications |

Marketed mainly for non-stick cookware and coatings |

|

Recognition |

Known primarily in technical and industrial contexts |

Highly recognized by the general public |

|

Other Brand Names |

Dyneon™, Fluon®, Hostaflon®, etc. |

Teflon™ only |

|

Availability |

Made by many manufacturers worldwide |

Only made and sold by Chemours under the Teflon name |

|

Analogy |

Like acetylsalicylic acid |

Like Aspirin |

The dielectric constant of PTFE is an important electrical property that measures how well the insulation material in an electric field stores electrical energy. The dielectric constant of PTFE is approximately 2.02, making it an extraordinary electric insulator.

Scientists define the dielectric constant as a relationship between the permittivity of a material and the free permittivity. This property determines how the material reacts to the reaction of electric fields and their polarization. The low value of PTFE suggests that it has a minimum electric polarization response.

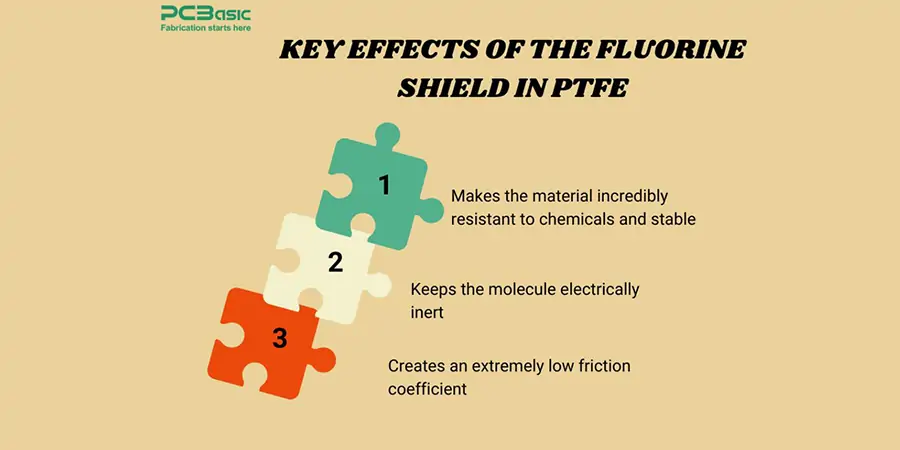

PTFE's low dielectric constant stems from multiple factors:

● Its fluorocarbon structure creates chemical and physical properties that lead to low dielectric loss and constant

● PTFE has a non-polar structure

● The molecular structure restricts electrical interaction

PTFE maintains stable properties under different circumstances. The dielectric properties of the material remain correspondingly different frequencies and temperatures. This stability makes PTFE perfect for applications that require reliable electrical performance despite changing environmental conditions.

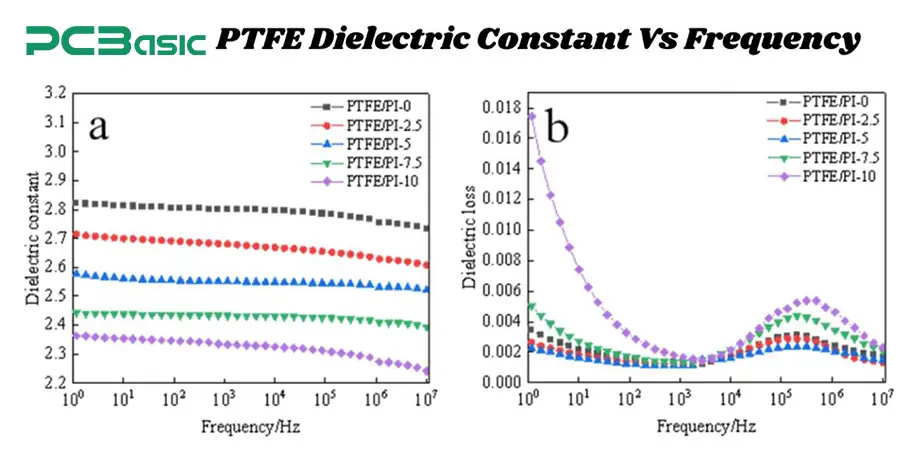

PTFE shows remarkable frequency stability. Research shows the dielectric constant stays steady at any given temperature. The computed change reaches only 0.001 across frequencies from 10² to 10⁵ cycles per second.

The largest longitudinal study examined temperature's effects on PTFE's dielectric constant. Measurements from room temperature to just below PTFE's transition point (327°C) reveal a slight decrease in dielectric constant as temperature rises. These changes are small enough that PTFE keeps its excellent insulating properties.

PTFE's combination of low dielectric constant and minimal loss makes it valuable, especially when you have high-frequency applications. The material's dielectric loss tangent values stay below 2×10⁻⁴. This will give a minimal signal degradation, which explains why PTFE remains popular in high-frequency and microwave applications.

PTFE's dielectric constant shows remarkable behavior under various conditions, making it stand out among electrical insulation materials.

|

Characteristics |

Description |

Significance |

|

Dielectric Constant Stability |

Remains unchanged under mechanical stress, deformation, and moisture exposure. |

Ensures consistent electrical performance in physically and environmentally challenging settings. |

|

Hydrophobic Nature |

PTFE does not absorb water. |

Maintains stable dielectric constant even in humid conditions. |

|

Volume Resistivity |

Exceeds 10¹⁸ ohm-cm, from cryogenic temperatures up to melting point. |

Provides excellent insulation with minimal leakage current across a wide temperature range. |

|

Chemical Inertness |

Resistant to chemical degradation and solvent exposure. |

Dielectric properties stay stable, even in chemically aggressive environments. |

|

Dielectric Strength |

Ranges between 19.7–21.7 kV/mm. |

Enables insulation against high voltages with minimal capacitive effects. |

|

Dielectric Behavior |

Semi-crystalline structure creates a balance of microscopic dielectric regions. |

Offers a stable macroscopic dielectric constant ideal for high-frequency signal transmission. |

|

Application Suitability |

Performs reliably in environments with mechanical stress, moisture, chemicals, and high voltage. |

Suitable for telecommunications, aerospace, and other high-frequency or critical electrical applications. |

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer that is characterized by good chemical resistance and thermal stability. Even though it has various advantages that make it appropriate for demanding applications, it also has some drawbacks that need to be taken into account.

PTFE has remarkable benefits that explain why it's widely used in various industries.

1. Exceptional Chemical Resistance

PTFE is resistant to nearly all corrosive chemicals and is, therefore the best choice for use in severe chemical environments. Few chemicals, such as molten alkali metals and fluorine at elevated temperatures, can impact it.

2. Thermal Stability

It is stable and functional in a wide temperature range between-268°C and +260°C. It is thus ideally suited for application in cryogenic systems and high-temperature manufacturing processes.

3. Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of solid materials. This property allows it to minimize wear and energy loss in mechanical devices, especially in moving parts like seals and bearings.

4. Excellent Electrical Properties

Because its dielectric constant is low, PTFE is extremely useful in the transmission of high-frequency signals. Additionally, its high dielectric strength and resistivity render it an ideal candidate for insulating parts in delicate electronics.

5. Non-reactive and Durable

PTFE's chemical stability makes it resistant to aggressive acids, bases, and solvents. This resistance extends the life of parts exposed to aggressive chemicals.

6. Versatility

Its ability to operate effectively in extremely low and high temperatures, coupled with its chemical and electrical characteristics, makes PTFE appealing to a broad range of industries and uses.

1. High Cost

PTFE is extremely expensive compared to regular plastics. This characteristic limits its use in cost-sensitive or mass-market usage, where expense is paramount

2. Poor Mechanical Properties

It is of low tensile strength and poor creep resistance and hence deforms under long-term stress. PTFE is typically reinforced with fillers to support mechanical loads.

3. Challenging to Manufacture

Unlike common thermoplastics, PTFE is still very viscous even at temperatures well above its melting point. This makes it impossible to use common processes such as injection molding and necessitates specialized, more expensive methods.

4. Radiation Sensitivity

PTFE is degraded by radiation and is, therefore, not suitable for applications involving radioactive environments or radiation sterilization.

5. Difficult to Bond

Its non-stick nature, although desirable in most applications, renders it difficult for PTFE to be bonded by adhesives or other materials. This is restrictive when building or integrating with other parts.

6. Recycling Challenges

Its chemical stability and high processing temperatures make recycling PTFE difficult. This creates environmental and sustainability concerns, especially for short-lived or single-use applications.

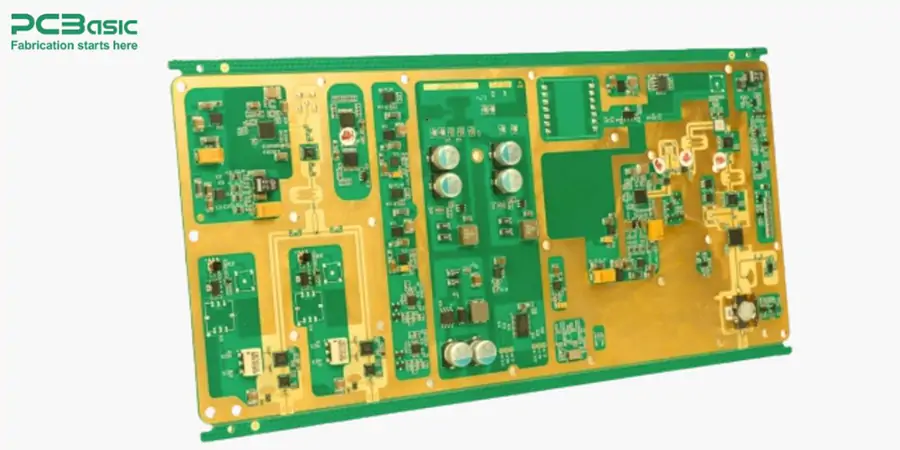

Polytetrafluoroethylene (PTFE), commonly referred to by the trademark name Teflon, is a high-performance synthetic fluoropolymer used in advanced printed circuit board (PCB) applications.

It is highly valued for its special electrical and physical characteristics that make it an ideal material for use in high-frequency, high-speed, and RF (radio frequency) applications. PTFE has a very low dielectric constant (usually approximately 2.1) and low dissipation factor, implying that it is able to transmit signals with negligible loss—a very important property for use in applications like 5G communications, radar, satellite devices, and aerospace technology. Besides superior electrical properties, PTFE is characterized by high thermal stability, chemical and moisture resistance, and endurance in harsh environmental conditions.

Nevertheless, its application in PCB manufacturing is fraught with challenges. The material's softness and flexibility also make it tougher to work with during production than with regular materials such as FR4. Because of its non-stick surface, drilling and plating require special processes, such as plasma treatments. All these intricacies and added expenses notwithstanding, PTFE is still a critical material in applications where signal integrity and dependability are not up for negotiation.

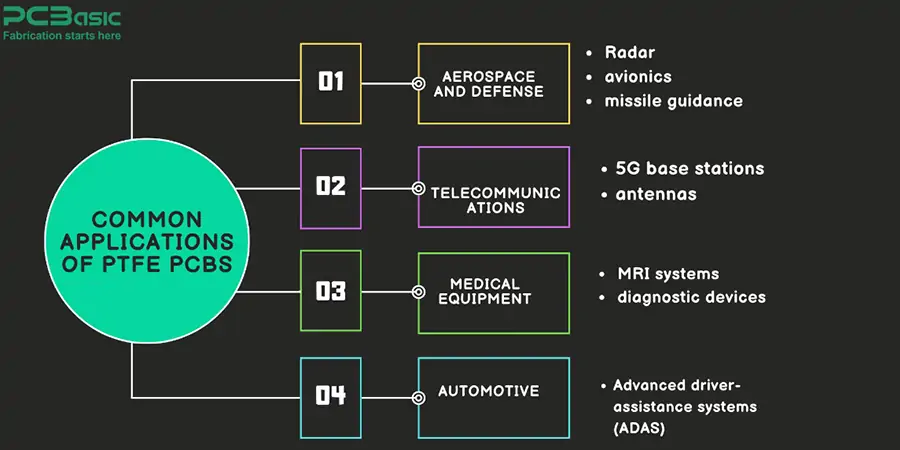

PTFE PCBs are typically found in:

Polytetrafluoroethylene (PTFE) has established itself as a key material in both industrial and high-performance electronic applications, and with good reason. Because of its outstanding electrical insulation, great thermal stability, and remarkable chemical resistance, it is an essential component in settings where dependability is crucial. One of its distinguishing features is a constantly low dielectric constant, which ranges between 2.0 and 2.1, ensuring little signal loss. That is why PTFE is frequently the preferred material in RF, microwave, and aeronautical systems where signal integrity is crucial.

In this blog, we look at what makes PTFE so successful, from its unique molecular structure to how it operates at different frequencies and temperatures. The distinction between PTFE and its well-known brand name, Teflon, was another major area of misunderstanding that we resolved.

Knowing the dielectric characteristics of PTFE may help you make better design choices and achieve more reliable performance, whether you're creating high-frequency electrical systems, studying cutting-edge materials, or just learning about the science underlying contemporary technology. PTFE has established itself as a reliable material in a variety of demanding sectors by continuously delivering where it counts most, despite a few drawbacks.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.