Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > How to design PCB board: a step-by-step guide for PCB design

PCB design is a well-discussed topic among qualified engineers and hobbyist makers. Many years ago, designing your custom pcb manufacturing might sound like a dream, but today you can quickly turn it into reality.

Although there are many PCB design services available, if you are serious about electronics, learning how to create and design PCBs on your own is crucial.

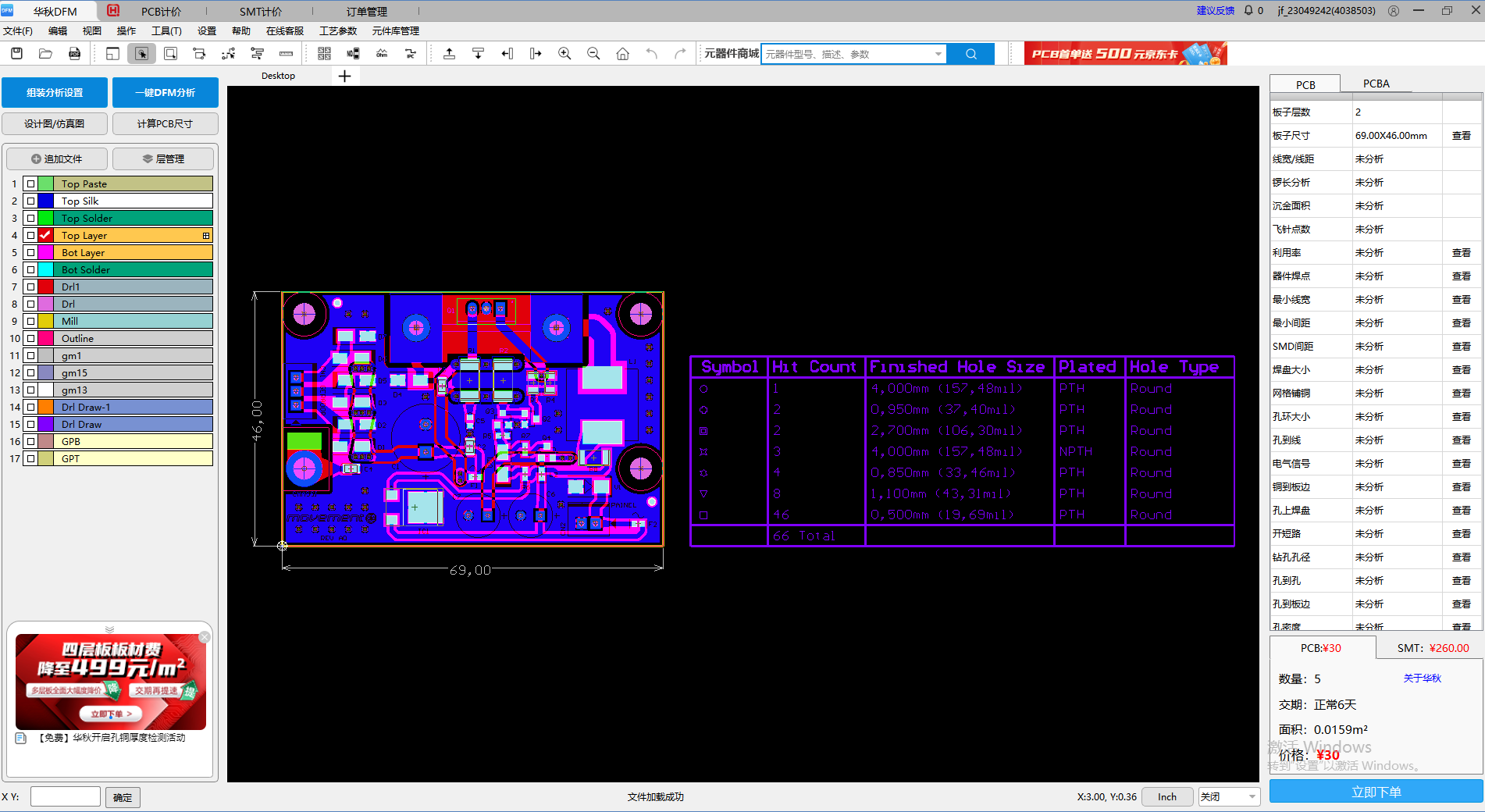

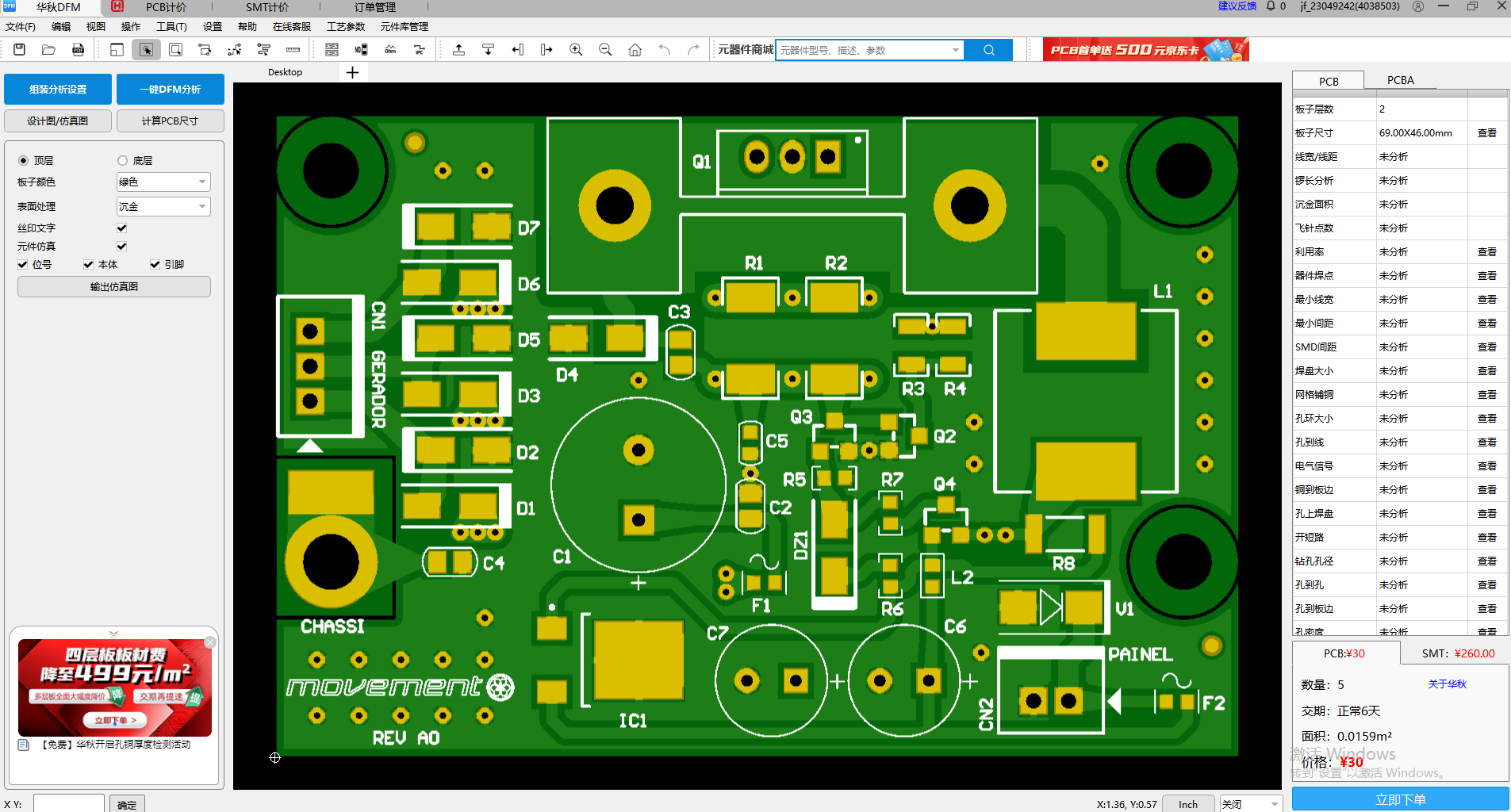

This article will walk through the recommended and most popular PCB design software. Using it, you will learn how to design schematic and layout for your custom design.

Finally, you’ll learn how to prepare custom BOMs and files for manufacturing. Such files are crucial when you are about to fabricate your PCB/PCBA, either in sample size or bulk.

Although many PCB design courses are available online, in this article, we will give a brief introduction to the world of PCB CAD design.

Finding a PCB design software can be a challenging journey. Many free PCB design software exists in the market and offers almost if not all the capabilities of advanced paid software. Some paid software might have a free version for personal use or a trial.

Earlier on, we wrote about the best PCB design software. If you are still determining which one is suitable for you, this article might help. If you are a student at University, you should look into a student discount which is often offered by most PCB board design software.

Eagle designer and Altium designer software are among the most popular software. Both PCB design software is considered trustworthy, convenient to use, and easy to start with.

Another nice feature is the ability to make a 3D CAD model out of the PCB design. Software such as Eagle designer connects to Fusion360 to create such power.

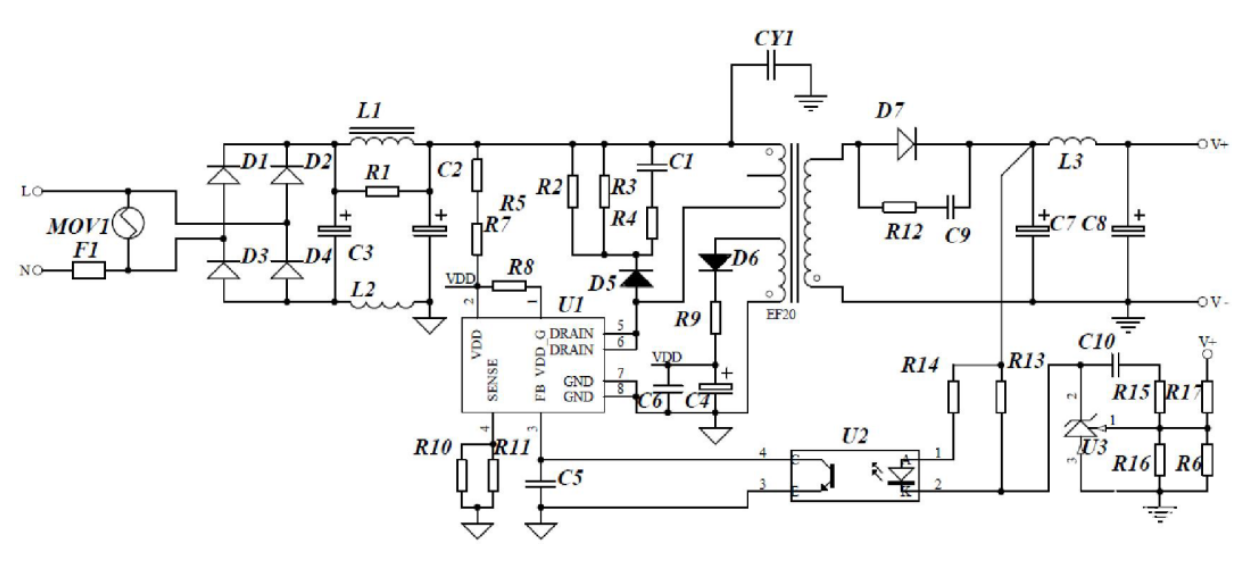

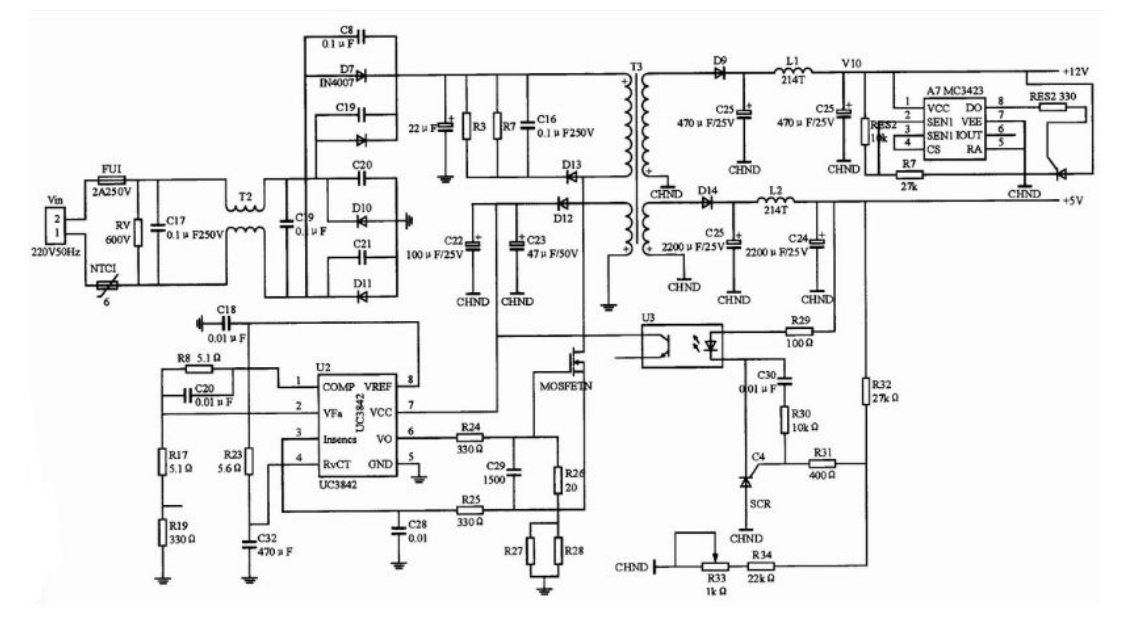

The first stage in designing your custom PCB board will be the schematic. The schematic is about building the logic behind the circuits. Connecting wires and components and deciding the footprint of every one of them. This stage is considered one of the most crucial stages in PCB design.

There are a few tips you can follow to ensure your design will be in the best shape possible:

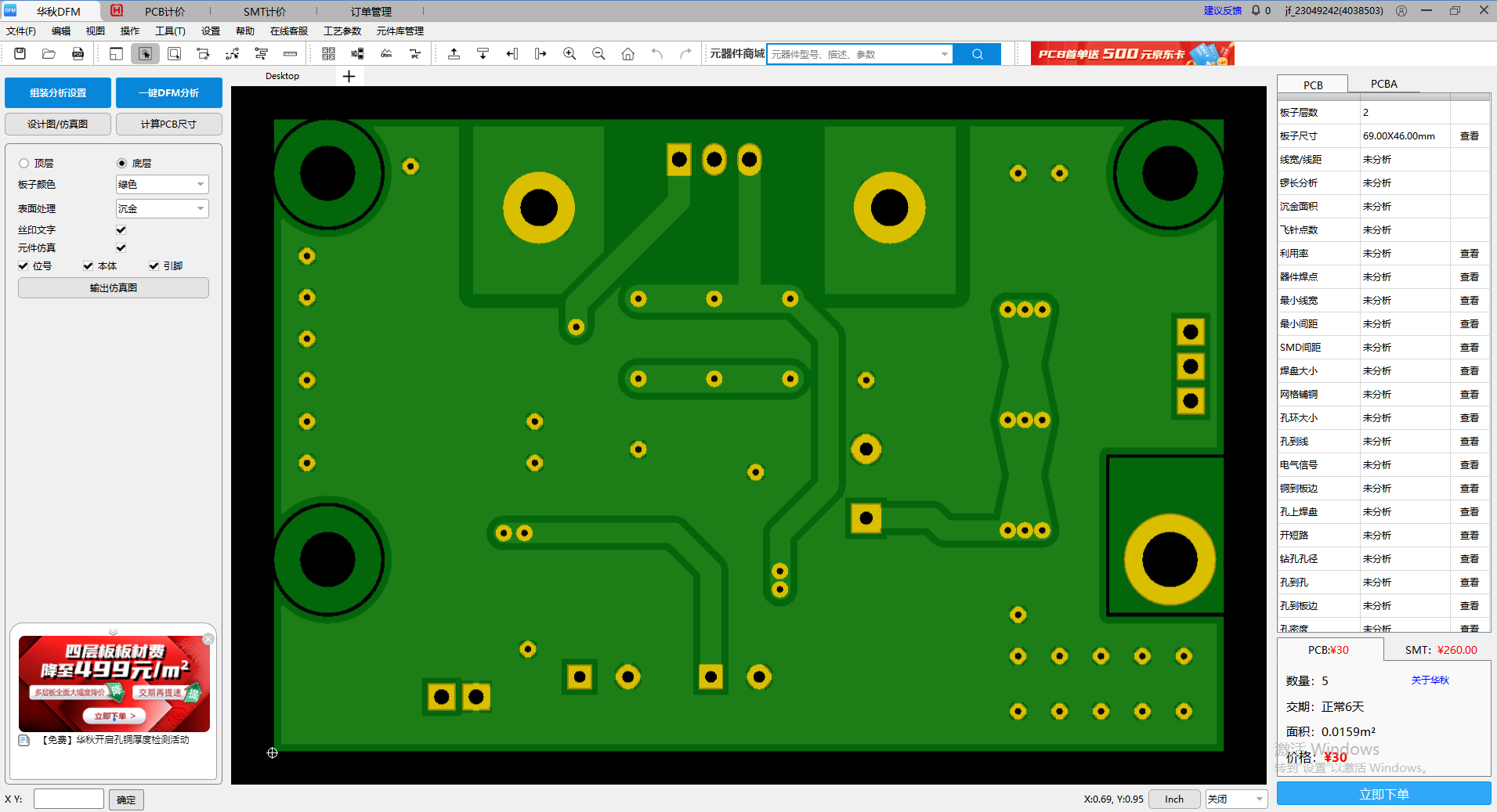

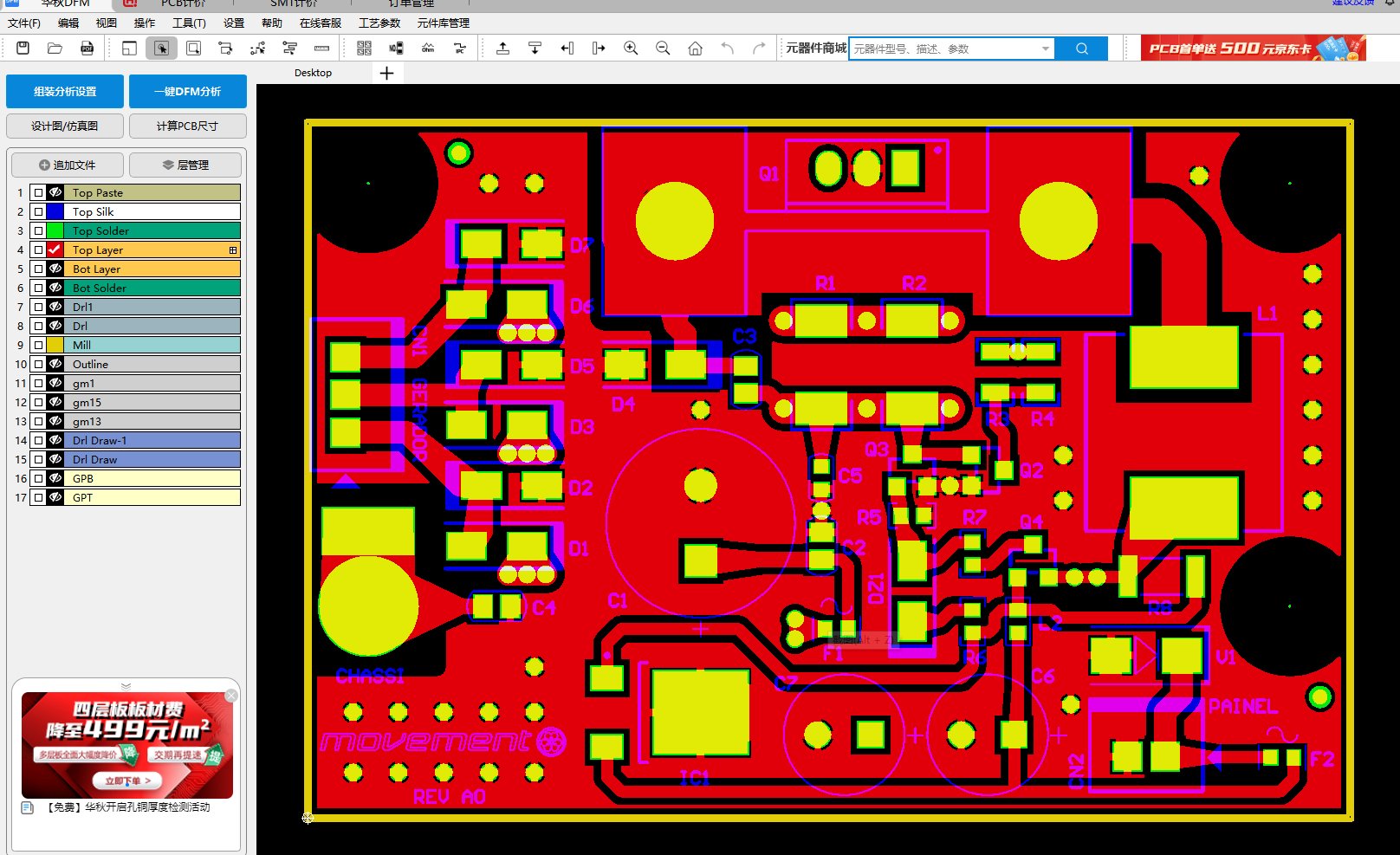

The layout is not less critical than the schematic design. Structure refers to setting the components on the PCB board, drawing the dimensions, and wiring the parts together.

Although it sounds pretty simple and fun, creating a layout for a PCB is crucial to ensure the integrity of the circuit board and the signal within it.

Multiple rules must be applied when designing a layout. Neglecting those rules of thumb could cause various issues that might be difficult to find. Circuit board signal and power issues often link to a layout design fault.

To ensure your design layout works perfectly as expected, follow the tips below:

A great design comes with a great BOM. Bill of materials (in short, BOM) is the file that indicates to the PCBA manufacturer what components to get and where to place them.

A good and easy readable BOM is crucial when designing a custom PCB project. Without it, the manufacturers might be led to make many mistakes and waste time, funds, and resources to identify what went wrong.

Most PCB designing software will offer an automatic BOM generator, but the most recommended way is to design one yourself. BOM generators get the information from the components packages, which might be partial or sometimes empty.

The most incredible tip for the best PCB BOM file would be clarity and the ability to understand the content of it quickly. Remember, the easier it is to read, the faster and better the PCB design can process for fabrication.

At PCBasic, we have years of experience in simple and complex PCB design creation. We can take it upon ourselves from the idea stage to mass production. If you are looking for a trustworthy partner to design your following product with, feel free to contact us for a quick quotation.

Among the online PCB designers community, we strive to provide our loyal customers with better and faster quality than the ones available in today’s market.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.