Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Flex PCB Material: A Comprehensive Guide

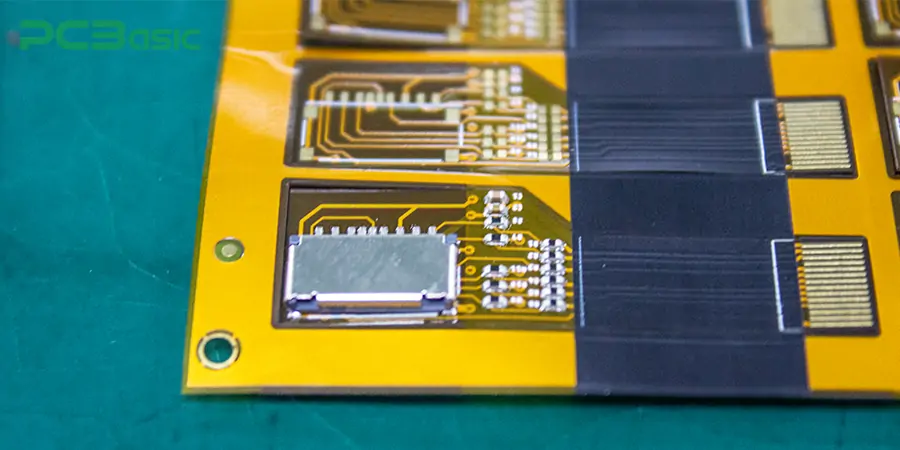

Flex PCB is a key technology for achieving slim and lightweight designs and space optimization in today's highly integrated and functionally intensive electronic products. Compared with traditional rigid boards, flexible circuit boards can be bent, folded and even twisted, thereby meeting the requirements of complex structures or dynamic devices. Therefore, as electronic devices evolve toward thinner, smaller, and more flexible designs, the demand for flexible printed circuit boards will continue to grow.

So, what materials are flexible circuit boards composed of? Today, let's explore the dedicated flex PCB materials together! This article will introduce in detail several core types of flex PCB materials and their physical properties, and analyze how these materials affect flex PCB manufacturing. Whether you are designing a simple flex circuit board or a complex rigid-flex PCB, choosing the right materials is the key to success.

Flexible PCB materials refer to the combination of flexible substrates, conductive layers, adhesives and protective films that make up flexible circuit boards. These materials are engineered to support repeated mechanical deformation without compromising performance. It is precisely because of these materials that circuit boards also have the ability to be bent, folded and even twisted without damaging their functions. To meet the installation requirements of the equipment in a small and three-dimensional space, choosing the appropriate flexible PCB material is of vital importance.

The properties of different flex PCB materials, such as heat resistance, dielectric strength, moisture absorption rate and flexibility, will directly affect the reliability of the product. Typical flex PCB structures include flexible substrates (such as polyimide PCB), copper conductors, adhesives, and coverlays for electrical insulation, and flex PCB stiffener material that provides local rigid support. Next, let's take a look at the specific flex PCB materials!

We will cover the core flexible PCB material in three parts: substrate films, coverlay & adhesives, and conductors. Materials not mentioned do not mean they are unimportant. Each type of material undertakes specific functions and jointly determines the structural strength, electrical conductivity and processability of the entire flexible PCB board. First of all, let's get to know the substrate material.

The substrate is the base layer of the flexible PCB board and determines its overall mechanical strength and thermal performance. The substrate film is the core layer of the flexible PCB board and is used to provide mechanical support and electrical insulation functions for copper conductors.

The most common flexible PCB material is polyimide. It has high thermal stability (> 200°C), strong resistance to chemical corrosion and excellent mechanical properties. It is widely used in high-reliability industries such as aerospace, automobiles, military industry and medical electronics, and is the first choice for scenarios with extremely high performance requirements.

PET is a kind of low-cost flexible PCB material (material for flex PCB), suitable for static applications in medium and low temperature environments. Although its heat resistance is not as good as that of polyimide, it performs well in consumer electronics such as LED light strips, membrane switches and disposable electronic products.

PTFE is renowned for its outstanding dielectric properties and extremely low dielectric loss. It is often used in radio frequency (RF), microwave and high-speed digital circuits, and is the preferred choice for high-frequency performance. However, it has poor flexibility and is difficult to process, so it is not suitable for flexible applications that require frequent dynamic bending.

LCP features excellent moisture resistance, low dielectric constant and stable high-frequency electrical performance. It is an increasingly popular flexible circuit board material in mobile devices, 5G antennas and high-frequency communication modules.

|

Performance Parameter |

Polyimide (PI) |

Polyester (PET) |

Liquid Crystal Polymer (LCP) |

Polytetrafluoroethylene (PTFE) |

|

Heat Resistance |

Excellent (>200°C) |

Moderate (≤150°C) |

Good (180–220°C) |

Outstanding (>250°C) |

|

Flexibility / Bend Durability |

ideal for dynamic flexing |

suitable for static use only |

limited flexibility |

not suitable for bending |

|

Dimensional Stability |

High |

Average |

High |

Moderate |

|

High-Frequency Electrical Performance |

Good |

Average |

Excellent |

Exceptional |

|

Moisture Resistance |

Good |

Poor |

Excellent |

Excellent |

|

Chemical Resistance |

Excellent |

Moderate |

Good |

Excellent |

|

Process Compatibility |

Strong compatibility with lamination and assembly |

Easy to process, suitable for volume production |

Requires controlled processing |

Difficult to process, needs specialized tools |

|

Cost Level |

Medium |

Low, cost-effective |

High, used for premium applications |

High, suited for high-frequency reliability |

|

Typical Applications |

Aerospace, automotive, medical, military |

LED strips, membrane switches, labels |

5G antennas, mobile RF modules, connectors |

RF modules, microwave devices, satellites |

The differences in flex PCB material properties among different types of substrate films are significant. Multiple aspects need to be considered to determine the selection of flex PCB substrate.

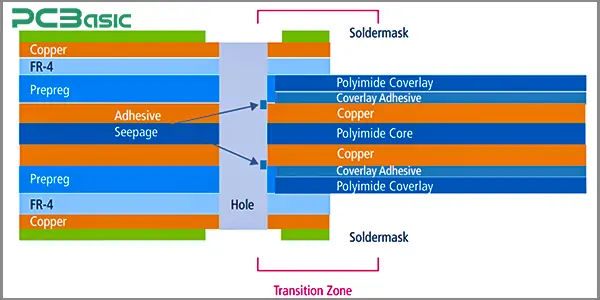

Unlike the solder mask ink used in traditional rigid PCBs, flexible PCBs more often adopt a structure of coverlay + adhesive to maintain good flexibility and heat resistance. The coverlay is used to protect copper wires and provide electrical insulation while maintaining the flexibility of the sheet.

The coverlay generally uses polyimide (PI) film as the main material. Because PI has excellent heat resistance and flexibility, it is highly suitable for use in the structure of flexible PCB materials.

Two types of adhesives, acrylic and epoxy, are usually used to firmly bond the coverlay to the surface of copper foil or substrate. Adhesive-free laminates are bonded directly through hot pressing, eliminating the need for additional adhesives. This method has the advantages of being thinner and more reliable, and is often used in high-end FPC or rigid-flex PCB materials.

Note: During the flexible PCB manufacturing process, it is necessary to ensure that the thermal expansion coefficients of the covering film and adhesive match those of the substrate and copper foil to avoid problems such as warping and delamination.

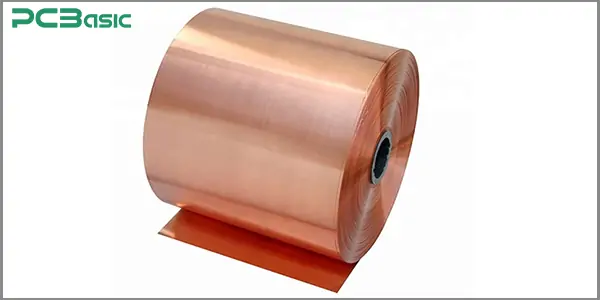

The choice of conductor type directly affects the process difficulty and reliability of flexible PCB assembly. In flexible PCBs, copper foil is the most commonly used conductor material. Copper foil is mainly divided into the following two types:

Rolled Annealed Copper: RA copper is a copper foil obtained through mechanical rolling and heat treatment processes. Its grain arrangement is more orderly, and it has excellent ductility and fatigue resistance. It is highly suitable for dynamic bending environments, such as wearable devices, camera modules, print heads and other repeatedly moving products.

Electrolytic Copper: ED copper is a copper foil manufactured through electrochemical deposition, featuring low cost and high efficiency in mass production. Although its flexibility is poor and its fatigue resistance is inferior to that of RA copper, it performs stably in static applications or disposable electronic products.

Although flexible PCBs themselves are bendable, additional mechanical support is still required in certain areas, such as connectors or mounting areas. At this point, flex PCB stiffener material is needed.

Common reinforcing materials include:

FR4 fiberglass board: Commonly used in connector areas

Polyimide (PI) : Consistent with the base material, facilitating process unification

Stainless steel/aluminium: It can provide extremely high rigidity and thermal conductivity

The stiffener is not part of the circuit layer but is attached to a specific area as a "non-electrical structure." It is often adhered to the back of the board through methods such as lamination, hot-pressing adhesive, and double-sided tape. In the process of flexible PCB manufacturing, the selection and position arrangement of the reinforcing layer usually need to be clarified at the design stage and have a direct impact on the subsequent flexible PCB assembly. Correctly integrating reinforcing materials in flexible PCB boards is the key to ensuring structural stability and process compatibility.

Selecting the appropriate flexible PCB material is an important step to ensure electrical reliability, mechanical properties and product durability. When evaluating flex PCB material, it is necessary to comprehensively consider application requirements, environmental conditions, cost budget and the compatibility of manufacturing processes. For example:

1. The working temperature range should be appropriate to ensure that the material does not delaminate or fail due to thermal stress.

2. If it is a dynamic application, the material needs to be able to withstand more than a million bends.

3. If impedance control is involved in the design, the electrical properties of the materials must be given priority.

4. If the design involves connector areas or structural reinforcement areas, consider whether the selected flexible PCB material is compatible with the flex PCB stiffener material used (e.g. FR4, stainless steel, PI).

In addition to the above suggestions, we also recommend following industry norms such as IPC-6013 (performance requirements for flexible PCBs) and IPC-2223 (design standards) to select the correct flexible PCB materials.

Selecting flex PCB material is a crucial step towards achieving high performance, reliability and cost-effectiveness. A good understanding of flex PCB materials is beneficial for the subsequent flex PCB manufacturing and assembly. Whether you are developing wearable devices or high-density rigid-flex boards, the various performances of the flexible circuit board material should be comprehensively evaluated. No single flex PCB material can be applied to all products. Therefore, before manufacturing flex PCBs, the material selection of flex PCBs should be carefully considered. Choosing the correct flexible circuit board material can not only reduce the failure rate, but also optimize the flexible PCB assembly process and improve the consistency and reliability of the products.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.