Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Circuit Board Manufacturing: A Complete Step-by-Step Guide

In the modern electronics industry, printed circuit board (PCB) manufacturing is the core technology behind every electronic product. From mobile phones and computers to industrial equipment, aerospace and medical devices, PCB manufacturing enables complex circuit systems to function properly within a limited space. With the development of technology, electronic products have become smaller, faster and more functional, and the requirements for the PCB manufacturing process are also getting higher and higher. Continuous optimization is needed to ensure performance and reliability.

However, for many people engaged in the circuit board industry, the entire circuit board manufacturing process is often rather complex and involves many technical details. This guide will explain the complete process from design, prototyping, and PCB fabrication to inspection in a clear sequence. Whether you are learning about how to make a PCB for the first time or are looking for a cooperative factory for large-scale PCB manufacturing and assembly, this article can help you have a comprehensive understanding of the key points and critical control methods in each phase of the custom circuit board, PCB prototype and large-scale PCB production.

Simply speaking, circuit board manufacturing is the process of turning an electronic design into a real and usable hardware product. The printed circuit board is the core component of all electronic devices and is responsible for transmitting electrical signals while fixing and supporting electronic components.

A complete PCB goes through multiple production steps. The entire PCB manufacturing process usually includes the following main processes:

• Prepare the design files;

• Select the right materials;

• Perform PCB fabrication, which builds the bare circuit board;

• Drill holes and plate them to connect different circuit layers;

• Do imaging and etching to form the circuit patterns;

• Apply surface finishing to protect the pads and conductors;

• Complete PCB assembly by soldering components onto the board;

• Finally, inspect and test the boards to ensure quality.

Nowadays, the demand for custom PCBs in many industries is increasing. Different products have special requirements in terms of size, performance, function and environmental adaptability, which also promotes the continuous innovation and improvement of PCB design.

In the process of PCB manufacturing, different application scenarios, product complexity and design requirements determine the type of circuit board. Before starting the printed circuit board manufacturing process, it is very important to understand these common types first:

1. Single-Sided PCB

The single-sided PCB is the simplest type. There is only one layer of copper on the circuit board, which is used to connect electronic components. This kind of board is usually used in electronic products with simple structures and single functions, such as calculators, radios or low-end household appliances. Because of its simple process, low cost and high production efficiency, it is very common in some low-cost and low-density application scenarios.

2. Double-Sided PCB

Both sides of a double-sided PCB have copper layers. Electronic components can be installed on both sides of the board, and circuits can also be connected to each other through vias between the two layers. This structure makes the circuit design more flexible and can accommodate more functions and components. Double-sided PCBs are widely used in consumer electronics, household appliances, industrial automation control systems and other fields.

3. Multilayer PCB

Multilayer PCB fabrication involves sandwiching insulating layers between multiple double-sided PCBs and then laminating them together through heating and high pressure to form one solid board. Multilayer PCBs can have structures of 4 layers, 6 layers, or even dozens of layers. It is suitable for carrying a large number of complex, high-speed and high-frequency circuit signals in the case of limited space. Multilayer PCBs are widely used in high-end fields such as servers, network communication equipment, high-end computers, aerospace and medical devices.

4. Rigid PCB

Rigid PCBs use hard substrate materials, such as fiberglass-reinforced epoxy (FR4), to keep the circuit board in a fixed shape and less prone to bending. Most traditional electronic products use rigid PCBs, such as mobile phone and computer motherboards. This type of board is easy to install and maintain, has high mechanical strength, and is suitable for the vast majority of standard electronic application scenarios.

5. Flexible and Rigid-Flex PCB

Flexible PCBs use soft materials (such as polyimide and polyester film), which can be freely bent, folded or rolled during use. They are suitable for scenarios with limited installation space or where dynamic bending is required. The rigid-flex PCB combines flexible and rigid materials, featuring both fixed support and flexible bending in a single board. This type of PCB is widely used in high-demand scenarios such as medical implant devices, wearable devices, military electronic systems and aerospace equipment.

Among these different types of boards, many products also need to be customized according to actual applications.

|

PCB Type |

Materials |

Key Features |

Typical Applications |

|

Single-Sided PCB |

FR4, phenolic resin, paper-based substrates |

Only one copper layer; simple structure; low cost; easy to manufacture and repair |

Calculators, radios, LED lighting, basic home appliances |

|

Double-Sided PCB |

FR4, CEM-3 |

Copper on both sides; components mounted on both sides; allows more complex circuits |

Consumer electronics, industrial controls, power supplies, printers |

|

Multilayer PCB |

FR4, high-frequency materials (PTFE, Rogers) |

4+ copper layers; supports high-speed, high-frequency, and compact designs; complex interconnections |

Servers, routers, aerospace systems, medical equipment, advanced computers |

|

Rigid PCB |

FR4, high TG laminates, metal core |

Fixed shape; high mechanical strength; reliable structure |

Smartphones, laptops, automotive electronics, industrial machines |

|

Flexible & Rigid-Flex PCB |

Polyimide (PI), polyester (PET), FR4 (for rigid parts) |

Bendable and foldable; combines rigid and flexible zones; ideal for space-constrained designs |

Medical implants, wearable devices, military electronics, aerospace instrumentation |

Through the custom PCB solution, engineers can flexibly select materials, the number of layers, board thickness, size and stacking structure, thereby better meeting the performance and usage requirements of the products.

Next, we will introduce in detail the complete PCB manufacturing process adopted by the current leading PCB manufacturing companies and PCB suppliers:

Every PCB manufacturing project starts with designing the circuit board. Engineers use software like Altium Designer, KiCad, or Eagle to draw the circuit diagram and layout. They define the width of copper traces, hole positions, component locations, and how many layers the board has. Once finished, the design is saved as Gerber files, which are the standard file format used for PCB fabrication.

Before starting full PCB manufacturing, PCB manufacturers review the design using DFM (Design for Manufacturability) checks. This helps to make sure the design matches the factory's production limits and avoids problems later. For custom PCBs and PCB prototypes, this step is very helpful in catching issues early and saving costs.

During the PCB fabrication stage, the Gerber files are used to create photofilms using laser photoplotters. These are clear plastic sheets with black patterns showing the circuits for each layer. The photofilms will later be used as templates to transfer the design onto the actual board. In multilayer PCB fabrication, registration holes ensure each film is perfectly aligned.

Clean copper sheets (laminates) are coated with a light-sensitive film called photoresist. The photofilm is placed over the laminate, and UV light shines through it. The areas exposed to light harden; the unexposed areas stay soft and are washed away. This exposes the unwanted copper, which is then etched away using chemicals, leaving only the required circuit pattern.

In circuit board manufacturing, inner layers are stacked together to create multilayer PCBs. The layers, prepreg (insulation layers), and copper foils are precisely aligned using machines. Then, heat and pressure press them together into one solid board. This multilayer PCB fabrication step is crucial for board strength, flatness, and proper connections between layers.

After lamination, holes are drilled using CNC drilling machines or lasers. These holes include vias (connecting layers), through-holes, and component holes. Accurate drilling is very important for good electrical connections. For complex custom circuit board designs, very tight drilling tolerance is needed to ensure proper copper plating later.

Inside the drilled holes, the walls are still non-conductive. A thin layer of copper is chemically deposited onto the hole walls using a process called PTH (Plated Through-Hole). This creates a conductive base for later copper plating, allowing current to flow between layers.

The outer layers go through a similar imaging process. The photoresist is applied, exposed to UV light, and developed to form the outer circuit pattern. Then, copper is electroplated onto the exposed areas to build up the copper traces and plate the hole walls. Finally, a thin layer of tin is plated on top to protect the copper during the next etching step.

The tin protects the copper traces while chemicals remove the unwanted exposed copper. After etching, the tin is stripped off, leaving clean and precise copper circuits. At this point, the complete circuit paths on the board are finished.

To prevent short circuits and solder bridges during PCB assembly, a solder mask is applied. A liquid photoimageable (LPI) solder mask covers the board, then UV light hardens the areas to be protected. The solder mask protects the circuits from oxidation, dirt, and physical damage during handling and use.

A silkscreen layer is printed on the board to show part numbers, component positions, version info, company logos, and product codes. This helps with the PCB assembly process, ensuring that components are correctly placed and making maintenance easier later.

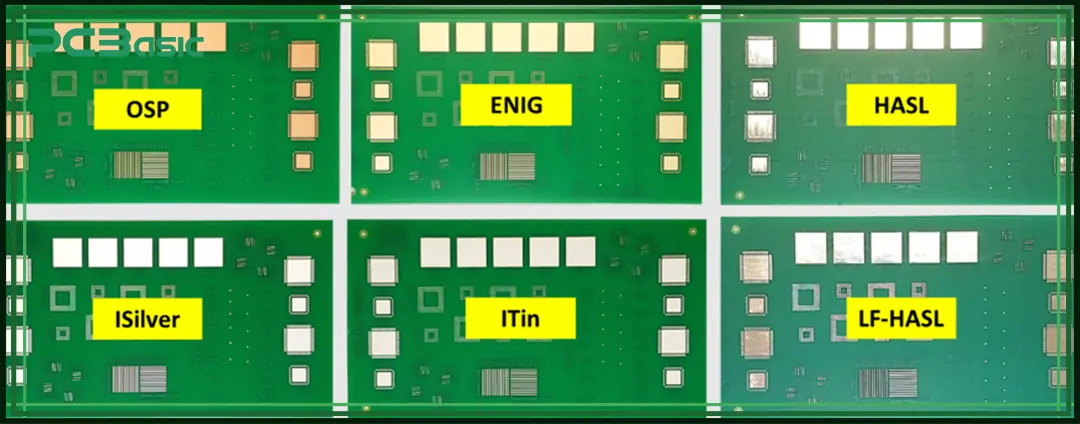

Exposed copper pads need finishing to improve soldering quality and prevent corrosion. Common surface finishes include:

• Hot Air Solder Leveling (HASL)

• Electroless Nickel Immersion Gold (ENIG)

• Organic Solderability Preservative (OSP)

• Immersion Tin / Immersion Silver

• Hard Gold Plating (for gold fingers)

Different custom PCB and PCB manufacturing and assembly projects require different finishes based on product needs, reliability, and cost.

After surface finishing, the board’s electrical circuits are tested. This includes checking for open circuits (missing connections) and short circuits (unwanted connections). Small batches are tested using flying probes; large batches use bed-of-nails fixtures. Any boards that fail are repaired or discarded to maintain quality.

CNC routers or V-cut machines separate individual boards from the large production panel. V-scoring cuts about one-third into both sides of the board, creating weak points that make breaking apart the boards easy. CNC routing is used for boards with custom shapes.

All custom circuit boards go through final inspections to check appearance, size, flatness, and cleanliness. Boards that pass are vacuum-packed with anti-static protection to keep them safe during shipping.

About PCBasic

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is a PCB assembly company that delivers fast, flawless results every time. Our comprehensive PCB assembly services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB assembly manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB prototype factory for quick turnarounds and superior results you can trust.

Even with advanced technology, printed circuit board manufacturing still faces several common challenges:

Drilling Accuracy Problems

If the drill holes are not positioned exactly right, the circuits may not connect properly, which can cause open circuits.

Copper Thickness Control

If the copper layer is too thin, it may not carry enough current. If it’s too thick, it can affect impedance, leading to signal distortion or overheating.

Solder Mask Defects

If the solder mask does not fully cover certain areas, it can cause solder bridges and short circuits during PCB assembly.

Uneven Surface Finishing

If the surface finish is not applied evenly, it can affect soldering quality, making components less stable and reducing long-term reliability.

Layer Alignment Errors

In multilayer PCB fabrication, even small misalignments between layers can ruin the whole board and make it unusable.

High-level PCB manufacturers and PCB suppliers use strict process controls and advanced AOI (Automated Optical Inspection) systems to detect and fix these issues early, ensuring high-quality circuit board production.

Before entering large-scale PCB production, creating a PCB prototype is very important. Through prototyping, engineers can check early whether the circuit board design meets the expected requirements, such as electrical performance, signal transmission, heat dissipation, and stability during actual use.

The prototype not only tests whether the circuit board works properly but also helps detect potential design and manufacturing issues in advance. For example, it may reveal problems such as unreasonable trace layouts, inaccurate hole positions, defective layer stacking, or difficulties in controlling production tolerances. If these problems are not identified during PCB manufacturing, entering mass production may result in large amounts of rework or scrap, increased costs, and project delays.

Many professional PCB manufacturing companies and PCB suppliers offer fast PCB prototype services to help customers quickly verify designs, improve solutions earlier, shorten product development cycles, and speed up time-to-market.

For custom PCB projects, prototyping also helps verify whether the entire PCB design and assembly process runs smoothly. For example, it checks whether components can be placed correctly, whether the soldering quality is good, and whether the assembly process is reasonable. This helps reduce risks before mass production and ensures stable production in the later stages.

Circuit board manufacturing has become the foundation of modern electronic technology. From design, PCB fabrication, and testing to PCB assembly, the entire PCB manufacturing process relies on precise techniques and advanced equipment.

Whether developing a new product or expanding production, it is important to work with experienced PCB manufacturers, PCB suppliers, and PCB manufacturing companies. This ensures stable product quality, reliable performance, and controlled costs. From custom circuit board development to large-scale PCB production, every step must be carefully controlled to ensure success.

By fully understanding how to make a PCB and mastering the complete printed circuit board manufacturing process, engineers and businesses can bring new products to market faster and more reliably.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.