Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

Global high-mix volume high-speed PCBA manufacturer

9:00 -18:00, Mon. - Fri. (GMT+8)

9:00 -12:00, Sat. (GMT+8)

(Except Chinese public holidays)

HomePage > Blog > Knowledge Base > Capacitor Polarity: A Comprehensive Guide

Capacitors are some of the most fundamental components of modern electronic systems. They play a critical role in the storage and regulation of electrical energy. Uses of capacitors include various applications, such as supply of power, filtering signals, and storing energy. This is quite interesting since capacitors come in several forms, and some kinds of capacitors must be mounted in a specific polarity for them to work. Hence, the importance of the polarity of capacitors.

Knowing how the polarity of the capacitor can be a huge issue is essential in achieving efficient circuits and safe outcomes for circuits, especially within PCBs, where improper placement leads to colossal loss or destruction. This article provides comprehensive information on capacitors regarding their polarity and the importance and relevance of different types of capacitance. It further indicates identification criteria and accurate application to enhance your decision-making skills related to capacitors while safeguarding your project results with improved performance.

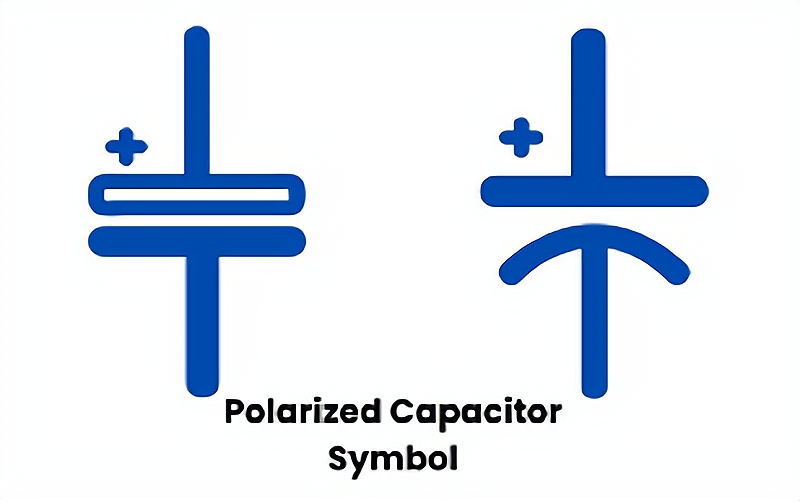

Capacitor polarity is how a capacitor is positioned within any given circuit. A polarized capacitor possesses a positive and a negative terminal. This feature of polarized capacitors creates an illusion that permits current to flow only in one direction toward the circuit. Consequently, the right connections of capacitors as they are employed would reduce damage or malfunction.

But, on the other hand, nonpolarized capacitors have no sensitivity towards the orientation and can be mounted in any direction. So polarity is very essential while selecting a capacitor for an application to avoid incompatibility in circuits.

Capacitor polarity is a very critical factor in the design and working of a circuit. Misaligned polarized capacitors may lead to the following:

●Circuit Malfunction: Even polarized capacitors can fail if electrolytic capacitors are misconnected; that is, they fit into the circuit incorrectly.

●Damage to Components: Reverse polarity can cause a capacitor to overheat, leak, or even explode, damaging other sensitive subcomponents mounted on the PCB.

● Reduced Efficiency: The reversed capacitor sometimes loses its preferred capacitance value.

Eventually, the system's efficiency for energy storage or signal processing was very low.

If special care is taken regarding the capacitor polarity while assembling, all such problems can be avoided, and your circuit will function perfectly and safely.

About PCBasic

Time is money in your projects – and PCBasic gets it. PCBasic is the pcb assembly company that delivers fast, flawless results every time. Our comprehensive PCB Assembly Services include expert engineering support at every step, ensuring top quality in every board. As a leading PCB Assembly Manufacturer, we provide a one-stop solution that streamlines your supply chain. Partner with our advanced PCB Prototype Factory for quick turnarounds and superior results you can trust.

Capacitors probably are the most essential component in electrical circuits. Their two main functions are that the capacitors store and then release energy appropriately. Several uses, including signal processing and energy storage, put them in a position that no one could do without them on modern circuitry. What's essential about a capacitor is its polarity, which sets how these devices would find their way in using circuits. These mainly come in polarized and nonpolarized. This section explains the nature, uses, and reason why polarity is necessary for the correct design of a circuit.

Polarized capacitors, such as surface mount (SMD) capacitor polarity, can be used in DC circuits and are always applied to the correct polarity for proper operation. In applications where high capacitance is needed in a very compact format, they work extremely well. Specific materials and construction techniques are used for polarized capacitors that enable them to withstand high energy levels; therefore, they are generally preferred in power-intensive as well as filtering circuits.

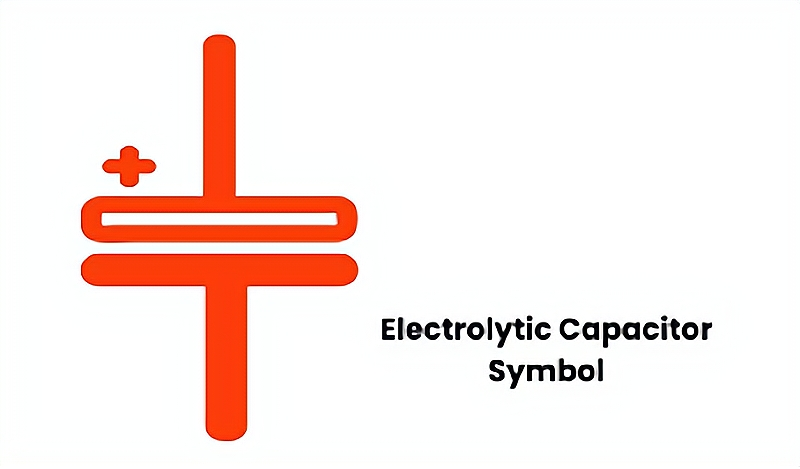

Electrolytic capacitors are the most widely available polarized capacitors because they have the most excellent capacitance per unit volume. The device consists of metal foil, an oxide layer, which forms the dielectric, and an electrolyte solution.

● High Capacitance: They range from 1 µF to thousands of µF to store quite a lot of electrical energy.

● Voltage ratings: They come in a very wide range of ratings from as low as 6V to over 500V, thereby giving way to diverse circuit requirements.

● Heat Resistance: It is usually stable between normal operating temperatures, but degradation occurs at extreme heat or extreme cold.

Electrolytic capacitors are the core of many applications

● Smoothing Filter: Filters the voltage noise; therefore, it supplies stable DC output to sensitive equipment.

● Signal Decoupling: Isolate AC signals in amplifiers, preventing DC biasing.

● Energy storage: It is widely used in backup power systems for critical devices such as servers and medical equipment.

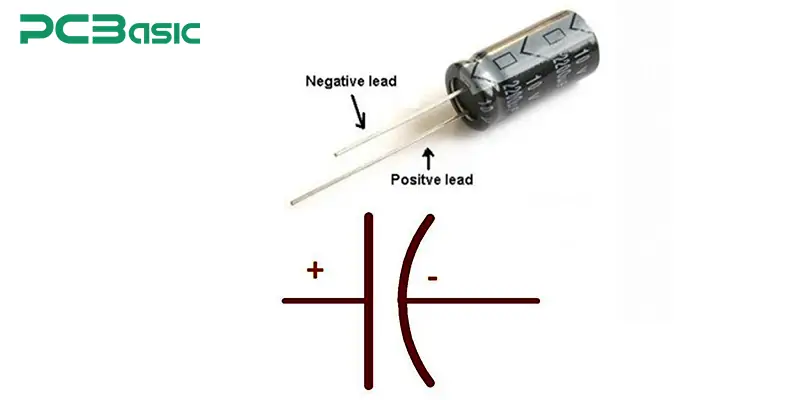

The opposing end of an electrolytic capacitor has a stripe, and in leaded types, the positive lead is more extended. Incorrect polarity may cause overheating, leakage of electrolytes, and catastrophic failure that can result in explosions.

Tantalum capacitor polarity is a very reliable polarized capacitor consisting of tantalum powder in a pellet format. The stability and accuracy are vastly better than that of aluminum electrolytic capacitors.

● Small size: much more petite than electrolytic capacitors of the same capacitance, making them ideal for space-constrained designs.

● Stability: It can deliver consistent performance over a wide range of temperature and frequency conditions.

● Durability: resistant to aging, hence implying long-term reliability.

● Consumer Electronics: It is used in mobile phones, laptops, and cameras because of their compact size and efficiency.

● Medical Devices: These are used in pacemakers and hearing aids, where precision and reliability are essential.

● Aerospace and Defense: Applied in high-performance systems that require high stability.

They are susceptible to wrong polarity and voltage spikes. Once damaged, it cannot be reversed.

Supercapacitors are also known as ultracapacitors. Their applications are those that imply a very high capacitance with fast charge/discharge cycles.They offer a unique combination of characteristics that bridge the gap between conventional capacitors and batteries. Although they have a higher energy density compared to conventional capacitors, their energy storage capacity is still much lower than that of batteries.

● High capacitance: The values reach thousands of farads and can store relatively high energies.

● Quick Response: Can charge and discharge quickly; suitable applications that require rapid energy transfer.

● Lifespan: Much more important than a conventional battery, it supports many charge/discharge cycles.

● Renewable Energy Systems: Balance Supply and Demand in Solar and Wind Power Sites.

● Electric Vehicles: Source of power surges for acceleration and regenerative braking systems.

● UPS: Those will give point-by-point, instantaneous short-period backup power during failure.

Despite their advantages, supercapacitors must obey the polarity constraints to avoid performance degradation and failure.

Nonpolarized capacitors can be mounted without any restriction in orientation. Being symmetrically constructed, successful usage for both AC as well as DC circuits also applies.

Ceramic capacitors are valued for low cost and reliable performance at high frequencies. There are several classes within the ceramic type depending on temperature stability and capacitance.

● Capacitance Range: a few pF to several µF.

● Handling High Frequencies: Suits high-frequency applications such as RF circuits and oscillators.

● Space-saving: For SMT on PCBs.

Ceramic capacitors used for noise suppression and decoupling are the most ubiquitous in consumer electronics and devices of communication.

Thin plastic film dielectrics are employed in film capacitors and provide high precision, stability, and large current-carrying ability.

● High voltage tolerant: Suitable for motor control and power factor correction applications.

● Lower ESR: It minimizes the energy loss in the circuit.

Applications include audio circuits for low distortion and motor start/running systems in HVAC.

Mica capacitors are made using natural mica as the dielectric and hence of excellent precision and stability. They are robustly constructed and, therefore, function dependably in extreme conditions.

● Oscillator Circuits: Ensure stable capacitance for accurate frequency generation.

● Aerospace Electronics: Reliability makes them widely used in satellite and defense systems.

They are expensive, but they possess special properties that are valuable for specialized applications.

The table below highlights the key differences between polarized and nonpolarized capacitors, aiding in selecting the right type for your circuit design:

Aspect

Polarized Capacitors

Nonpolarized Capacitors

Dielectric Material

Dielectric materials such as aluminum oxide or tantalum pentoxide are typically used. Such materials have high capacitance in a small size but limit the capacitor to only one polarity orientation.

These are made from ceramic, plastic films, or mica that allow for versatility and bidirectional operation. The dielectrics are stable both for AC as well as DC circuits.

Performance

They hold a lot of charge in a small volume, though they are polarity-sensitive, so they may fail if incorrectly connected.

They have less capacitance than polarized but score high on stability and reliability in all frequency ranges. Orientation is not a problem for them.

Capacitance Range

Application in energy storage and filtering capabilities with capacitance values from 1µF to several thousand µF.

Capacitance between a few picofarads and several microfarads, allowing for signal processing and coupling without having critical high capacitance.

Lifespan

Affected by electrolyte degradation; polarity reversal can significantly shorten lifespan.

More robust and durable, not polarity-sensitive, and typically longer-lasting in high-frequency circuits.

Temperature Range

-40°C to +85°C for standard models; up to 125°C for high-temp models.

-55°C to +125°C, suitable for harsh environments.

Structural Appearance

Often cylindrical with clear designations for polarity. Electrolytic capacitors will have a stripe on the negative terminal and a longer lead on the positive terminal for better identification.

They come as discs, boxes, and rectangles without any polarity indications, hence their easier installation to circuits.

Voltage Handling

Designed for DC circuits, with voltage ratings from 6V to 500V.

Suitable for AC and DC circuits, voltage range varies from a few volts to several kilovolts.

Usage Scenarios

Used in circuits that demand high capacitance and stable energy storage, like power supplies, audio amplifiers, renewable energy systems, etc.

In those applications where high-frequency circuits, AC signal coupling, RF systems, or motor start/run require bidirectional voltage handling.

Capacitors are one of the most important components in daily electronics and modern industrial systems. Their utilization highly depends on their polarities and characteristics.

High capacitance applications, especially requiring a robust capability of reliable energy storage.

●Power Supply Filtering: Filtering for Power Supply To smooth out the voltage ripples for DC output, especially with sensitive electronics like microcontrollers and amplifiers.

●Audio Amplification: Provides a very clean sound in an audio circuit by filtering and stabilizing audio signals.

●Energy Storage in Renewable Systems: Store and release energy in solar inverters and wind turbines to be able to operate continuously.

Nonpolarized capacitors are better suited for AC signals and high-frequency circuit applications.

●RF and oscillator circuits: For stabilized signal processing and frequency generation in communication equipment, RF and oscillator circuits are necessary.

● AC Signal Coupling: Filter out DC components and pass AC signals to the amplifiers.

● Motor Start/Run Systems: Gradually start the motor for smooth operation in HVAC systems and industrial equipment.

Understanding the specific uses of polarized and nonpolarized capacitors ensures proper use, which gives extra circuit performance and robustness.

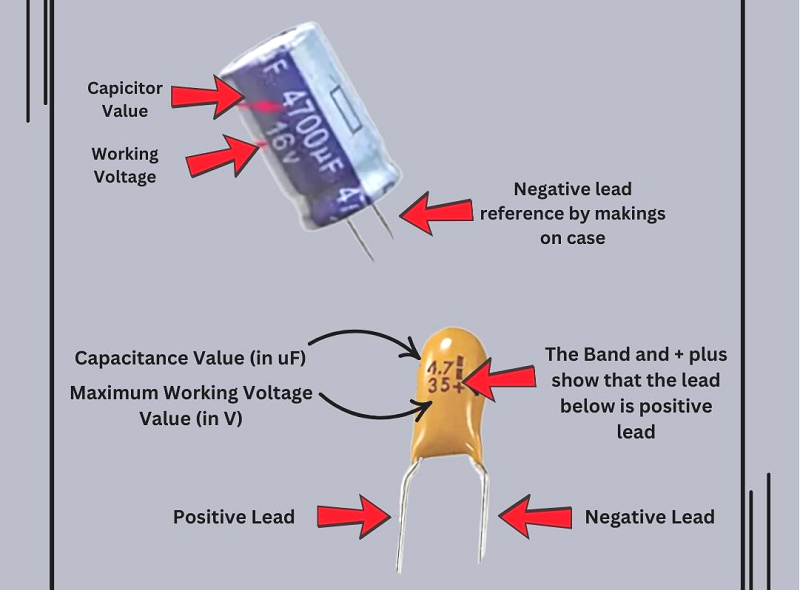

The most important thing related to the identification of the polarity of a capacitor is so that it can work effectively and not get damaged in an electronic circuit. Electrolytic capacitors, among others, tantalum capacitors have a specific capacitor polarity markings in respect of the orientation of their positive as well as negative terminals.

The most common way of indication is through a stripe or an arrow on the capacitor body itself to point to the negative terminal. Others, use symbols like a "+" sign to mark the positive terminal. Other methods make use of the difference in the length of the pins, with the longer lead that indicates the positive terminal. Some special types of capacitors have polarities marked with chamsfering or color code for easy identification.

Other means and equipment can be applied in determining the polarity save for the visual marks. The data sheets of manufacturers can also be a means of establishing the polarity. Normally, they include the drawings and specifications meant for good installation. If all those are not available, check the packaging of the capacitor as most manufacturers print all details of the polarity at the box.

Another good tool for testing for polarity is a multimeter. You put its probes onto the leads of the capacitor with your multimeter set into resistance mode, and you see the resistance reading change. Oriented properly, you know some kind of rising pattern for the resistance value as it charges up to determine which one is positive and which is negative.

This knowledge would ensure capacitors were used properly so the circuit could be assembled without costly mistakes.

Polar reversed can, in destructive mode, adversely affect both the component and the circuit. This is because polarized capacitors such as electrolytic and tantalum may fail cataclysmically if installed or oriented incorrectly.

Reversed polarity most likely causes short circuits immediately. The dielectric of the capacitor breaks up in opposition to what it is supposed to hold and, therefore, fails from an inside perspective. It causes great heat, probably blasting or leaking hazardous substances.

Reverse polarity not only damages the physical aspect but also affects the circuit's performance. Some capacitors, like filters or energy storage capacitors, may malfunction if not oriented correctly. This can result in a bad signal quality, unstable voltage, or even a failure in delivering energy.

Capacitor shorting damages the surrounding parts of the PCB. Heat, as well as electrical shock arising from the faulty component, can over-stress the adjacent resistors, transistors, or integrated circuits to damage circuitry reliability.

Moreover, make sure the polarity is correct for the right installation so that both the capacitor and circuit would not get destroyed when installed.

Proper polarity of capacitors during assembly on a PCB is very important for circuit integrity and safety. There are several ways that ensure the right orientation of polarized capacitors.

First, find the polarity marks on the capacitor and on the PCB. Most of the PCBs mark the locations to connect the plus terminal correctly by a ' + ' symbol or the shape of the pads. Comparing marks on the capacitor minimizes errors at the time of assembly.

Following testing of the capacitor's polarity with good test equipment - possibly multimeters before soldering onto the board, one will have the additional confidence of knowing that at the installation, the terminal orientation has been checked using the testing equipment.

Equally important is the consulting of datasheets of various manufacturers to have an accurate determination of appropriate use and installation for certain types of capacitors. Datasheets become critical in more complicated designs or for unknown parts.

Finally, checking each component before the final assembly reduces errors. A final look at the capacitor's orientation also saves time and resources if possible circuit failures are avoided, especially in high-stakes applications.

From all this, a PCB can easily follow all these processes to ensure assured operations for its engineers.

Capacitor polarity is very important in electronic design. Only correct orientation gives security and high performance of the circuit; otherwise, the wrong orientation may result in the failure of the component elements, low performance, or even damage to other components within the circuit.

For example, the utilization of instruments such as polar markings testing instruments and others ensure that the situation is not averted. Proper, correct, and careful assembly of PCBs affords the protection of design in its own guaranteed optimal performance. Good knowledge of the polarity of a capacitor is integral for reliable electronic design.

Assembly Enquiry

Instant Quote

Phone contact

+86-755-27218592

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

Wechat Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.

WhatsApp Support

In addition, we've prepared a Help Center. We recommend checking it before reaching out, as your question and its answer may already be clearly explained there.